Heating units, high-frequency furnaces and roll units for hot stamping

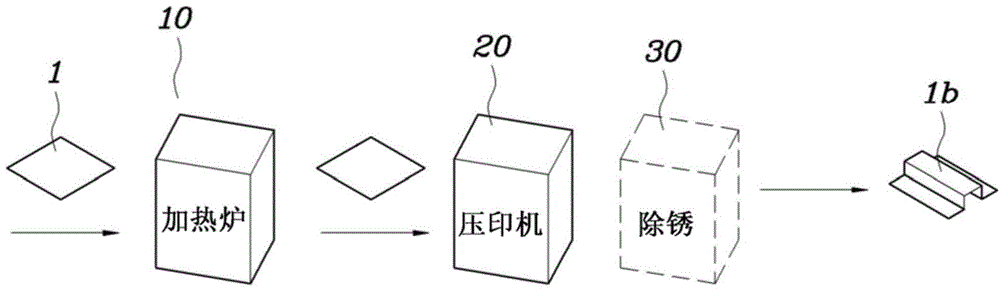

A heating device and hot stamping technology, applied in the fields of heating devices, high-frequency heating furnaces and roller units, can solve the problems of excessive increase in the temperature of the steel plate and deformation of the steel plate, and achieve the effects of increasing productivity, reducing fuel costs and reducing installation space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, a heating device for hot stamping, a high frequency furnace, and a roll unit according to an embodiment of the present invention will be described with reference to the accompanying drawings.

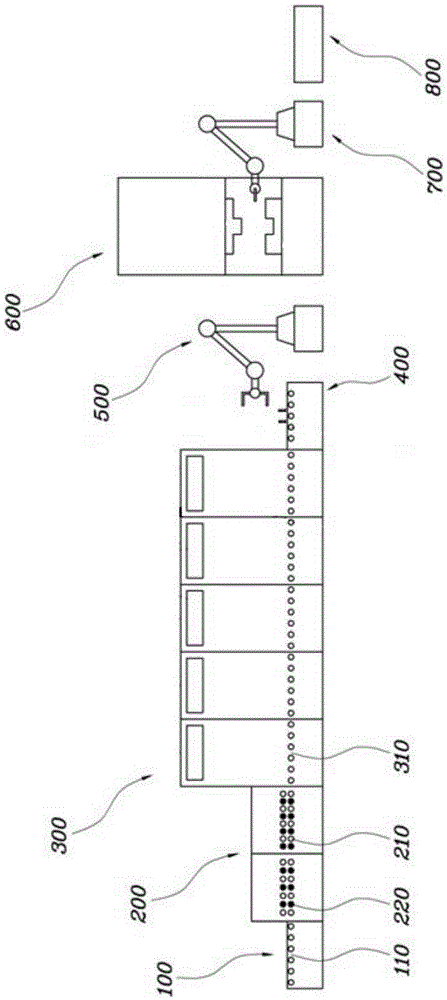

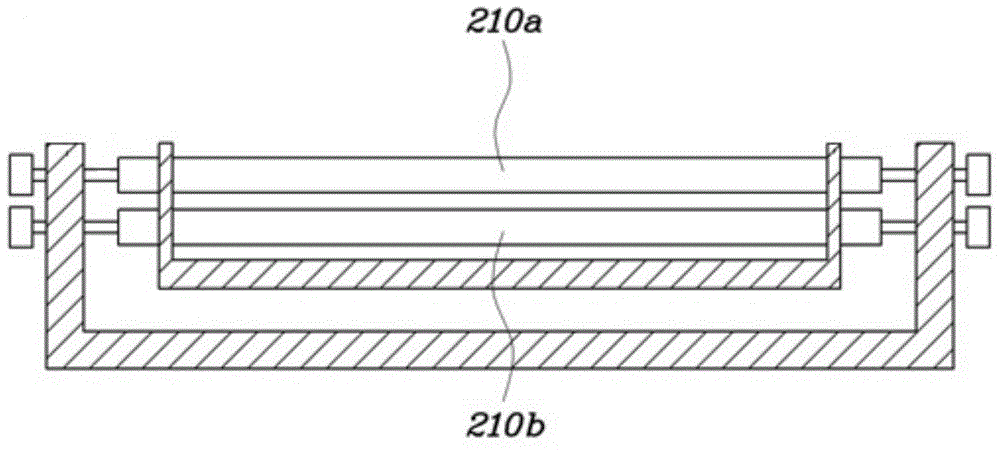

[0034] figure 2 is a view showing a heating device for hot stamping and an imprinter according to an embodiment of the present invention. image 3 is showing figure 2 View of the upper and lower rolls in the first furnace. Figure 4 is showing image 3 The top perspective view of the upper roller and the lower roller in ;

[0035] A heating device for hot stamping according to an embodiment of the present invention includes a steel plate supply unit 100; a first heating furnace 200, a plurality of pairs of upper and lower rollers 210 and a plurality of high-frequency coils 220 for transferring a steel plate in the longitudinal direction of the device installed in the first furnace 200; and an extraction unit 400 from which the steel plate is unloaded.

[0036]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com