Bionic bone-chopping knife

A bone knife and bionic technology, applied in manufacturing tools, hand-held tools, metal processing, etc., can solve the problems of shortened service life and difficulty in raw meat processing, and achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

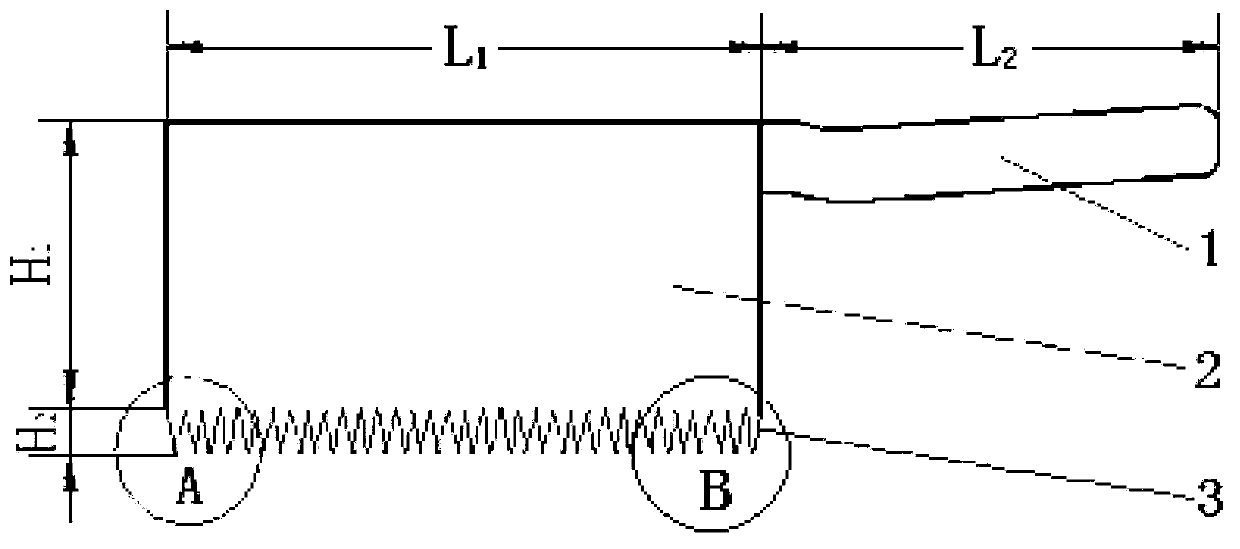

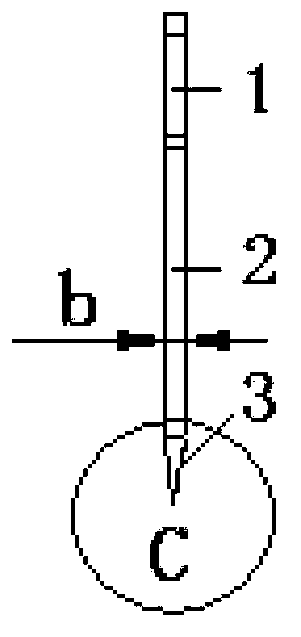

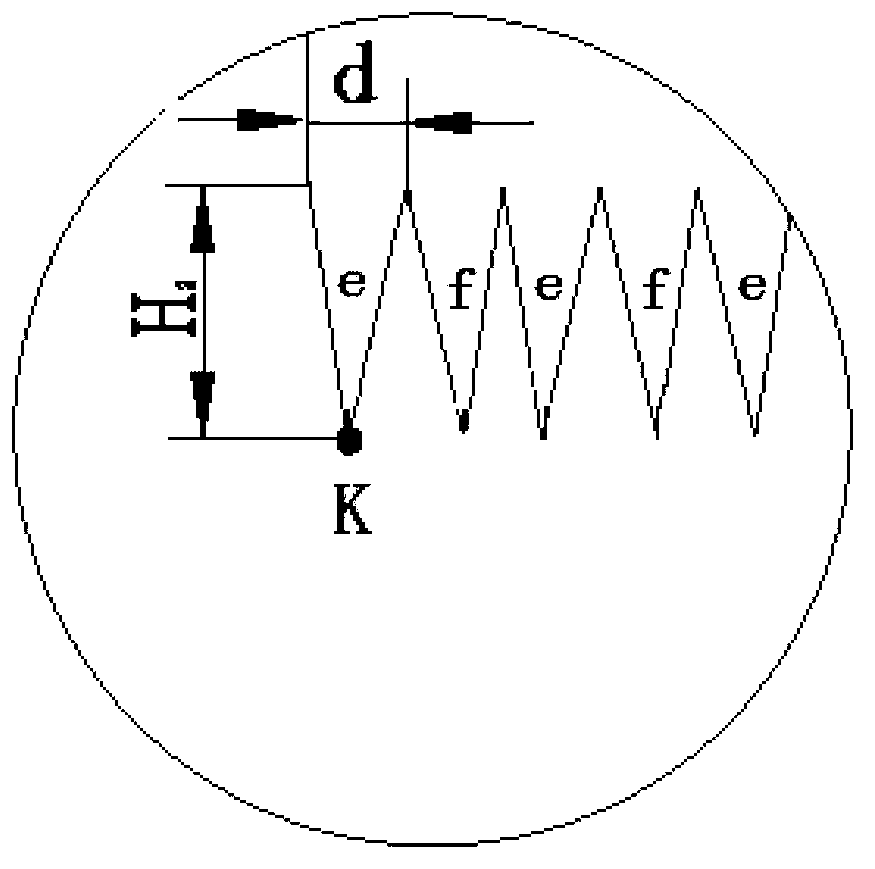

[0028] Example 1: The bionic bone chop knife of the present invention, the length of a single tooth is H 2 4mm, the width d of the large end of a single tooth is 2.5mm, the length of the blade and the length of the cutter body L 1 Both are 165mm, the tool handle length is L 2 145mm, the width of the cutter body H 1 Is 75mm. The thickness b of the cutter body is 2.5mm, the expansion angle θ is 70°~0°, and the starting point k point (see image 3 ) To the end cutter tooth point M point (see Figure 4 )slowing shrieking.

example 2

[0029] Example 2: The bionic bone chop knife of the present invention, the length of a single tooth is H 2 2.6mm, the width d of the large end of a single tooth is 2mm, the length of the blade and the length of the blade L 1 All are 160mm, the length of the handle l 2 140mm, the width of the knife body H 1 Is 70mm, the thickness of the cutter body b is 2mm, the expansion angle θ is 70°~0°, and it starts from the starting tooth point k (see image 3 ) To the end cutter tooth point M (see Figure 4 )slowing shrieking.

example 3

[0030] Example 3: The bionic bone chopping knife of the present invention, the length of a single knife tooth is H 2 7.5mm, the width d of the large end of a single tooth is 3mm, the length of the blade and the length of the cutter body L 1 Both are 170mm, the handle length is L 2 150mm, cutter body width H 1 Is 80mm, the thickness of the knife body b is 3mm, the expansion angle θ is 70°~0°, and the starting knife tooth point k point (see image 3 ) To the end cutter tooth point M (see Figure 4 )slowing shrieking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com