Induction heater and method for realizing non-preheating cladding of alloy on steel rail by using same

A technology of induction heater and cladding alloy, which is applied in the direction of fusion spraying, metal material coating process, coating, etc., can solve the problems of heat energy consumption, waste of heat energy, and affecting normal flaw detection of public works, so as to save energy and increase heating range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

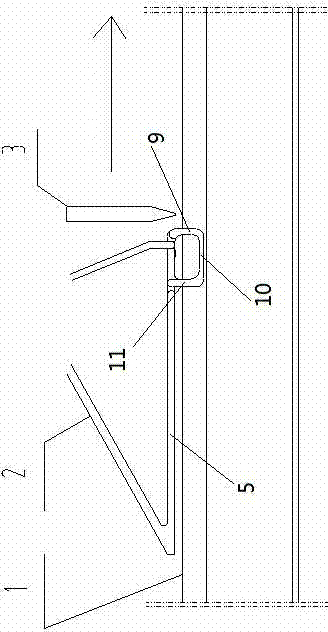

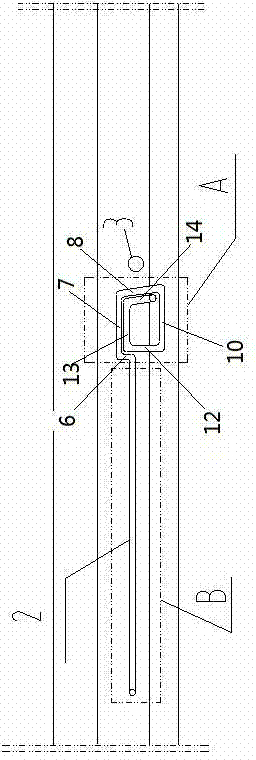

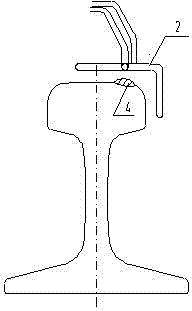

[0068] The invention discloses an induction heater, which comprises a heating zone A and a heating zone B. The heating zone A is divided into two heating surfaces, the shape of the first heating surface is a trapezoid without a bottom, and the second The shape of the first heating surface is U-shaped, and the two waists of the trapezoidal heating surface are connected with the U-shaped heating surface. There is an included angle between the first heating surface and the second heating surface, and the specific included angle The degree can be adjusted according to the shape of the rail in actual application; the heating zone 2B is a "one"-shaped structure, the heating zone 2B is connected to the first heating surface, and the heating zone 2B and the first heating surface On the same level, during specific heating, the heating zone 2B and the first heating surface are located on the upper part of the rail cladding belt, and the second heating surface is located outside the rail ...

Embodiment 2

[0070] As a better improvement of the present invention, the included angle between the first heating surface and the second heating surface is 90 degrees, that is, the entire heater is in an "L" shape as a whole, which can achieve better application effects, and the heating Zone 1A and heating zone 2B are formed by bending, bending or welding copper or silver tubes, which can reduce production costs and facilitate one-time molding. The rest of the structure is the same as that of Embodiment 1.

Embodiment 3

[0072] Refer to attached Figure 4 , the copper or silver tube includes the first section 5 on the horizontal plane, the second section 6, the third section 7, the fourth section 8, the eighth section 12 and the ninth section 13, and the fifth section on the vertical plane Section 9, the sixth section 10 and the seventh section 11, the first section 5 is heating zone 2B, the second section 6, the third section 7, the fourth section 8, the eighth section 12 and the ninth section 13 surround the formed The trapezoidal first heating surface lacking the lower bottom, the fifth section 9, the sixth section 10 and the seventh section 11 are connected to form a U-shaped second heating surface, according to the first section 5 to the ninth section 13 Each section is sequentially formed by copper or silver tubes. The third segment 7 and the ninth segment 13 together form the upper bottom of the trapezoidal heating surface, the cross-sectional shape of the third segment and the ninth s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com