Black polymerizable composition and method for producing black layer

A technology of composition and black layer, which can be applied in the direction of photographic process, coating, and photosensitive materials used in optomechanical equipment, etc., can solve the problems that the research on the resistance of alkali developer has not been fully carried out, and achieve extreme The effect of good shading characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0391] Hereinafter, the present invention is described in detail with reference to Examples without departing from the spirit of the present invention, but the present invention is not limited to the following Examples. In addition, "%" and "parts" are by mass unless otherwise specified.

[0392] Preparation of Titanium Black Dispersion (TB-1 Dispersion)

[0393] The components shown in Composition I below were subjected to a high-viscosity dispersion treatment using a double roller to obtain a dispersion liquid. The viscosity of this dispersion was 40,000 mPa·s.

[0394] In addition, the components may be kneaded for 30 minutes using a kneader before the high-viscosity dispersion treatment.

[0395] (composition I)

[0396] Titanium black 13M-C with an average primary particle diameter of 75 nm (manufactured by Mitsubishi Materials Electronic Chemicals Co., Ltd.) (Pigment Black 35)

[0397] 40 copies

[0398] ・Propylene glycol mo...

example 1 to example 5 and comparative example 1 and comparative example 2

[0426] 1. Preparation of black polymerizable composition

[0427] The components of the following composition A-1 were mixed using a mixer to prepare each black polymerizable composition used in Examples 1 to 5 and Comparative Examples 1 and 2.

[0428] (Composition A-1)

[0429] ・(D) 2.5 parts of alkali-soluble binder polymer described in Table 1

[0430] (C) Polymerizable compound: 2.0 parts of dipentaerythritol hexaacrylate

[0431] (C) Polymerizable compound: 1.0 parts of pentaerythritol triacrylate

[0432] ・(B) 0.3 parts of the polymerization initiator described in Table 1

[0433] 24 parts of the dispersion containing (A) black pigment described in Table 1

[0434] ·Propylene glycol monomethyl ether acetate 10 parts

[0435] ·8 parts of cyclohexanone

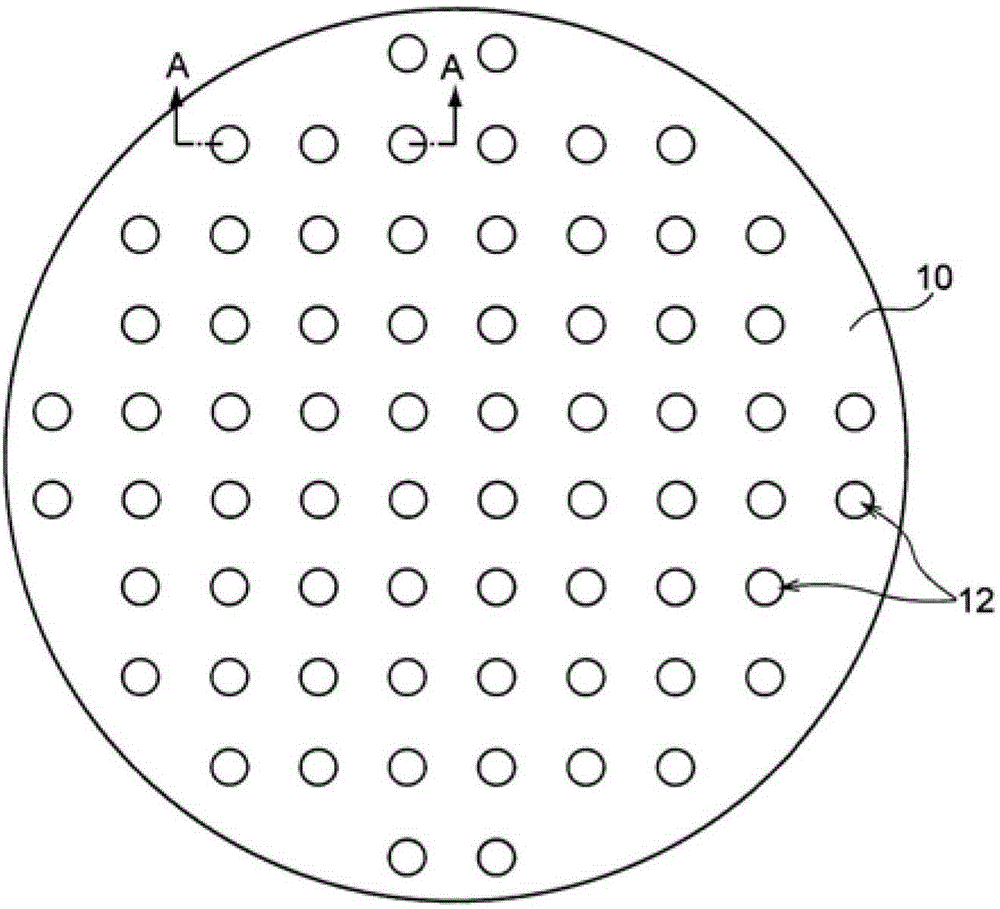

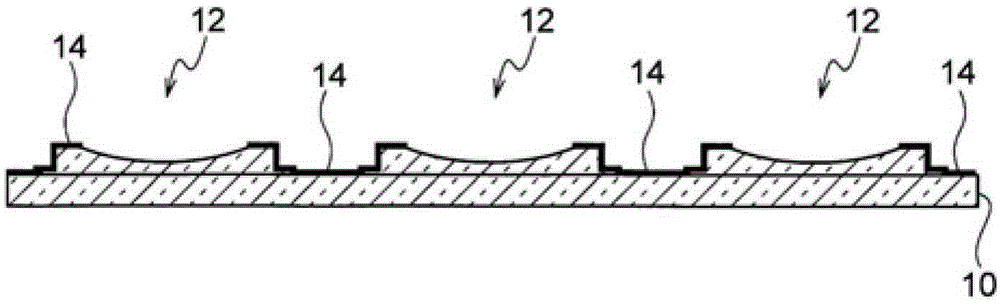

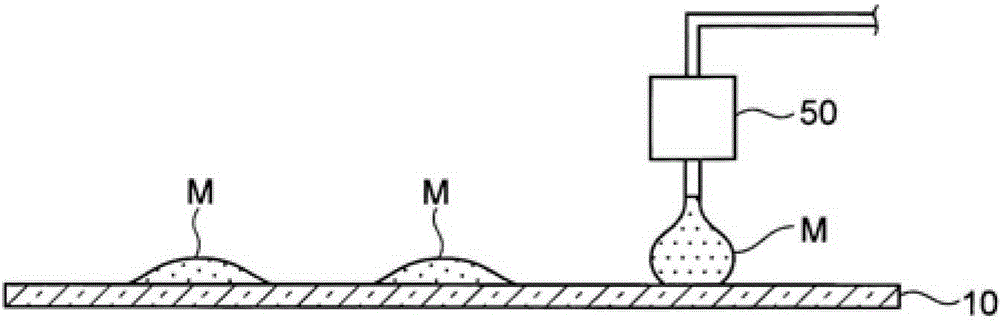

[0436] 2. Manufacture and evaluation of shading film (shading area)

[0437] Each black polymerizable composition obtained above was coated on a glass wafer by spin coating, and heated on a hot plate at a temperatu...

example 6 to example 10 and comparative example 3

[0451] 1. Preparation of black polymerizable composition

[0452] The components of the following composition A-2 were mixed using a stirrer, thereby obtaining the black polymerizable compositions of Examples 6 to 10 and Comparative Example 3, respectively.

[0453] (Composition A-2)

[0454] ・(D) 2.5 parts of alkali-soluble binder polymer described in Table 2

[0455] (C) Polymerizable compound: dipentaerythritol hexaacrylate monomer modified with succinic acid

[0456] 2.0 copies

[0457] (C) Polymerizable compound: 2.0 parts of pentaerythritol triacrylate

[0458] 0.1 parts of 3-methacryloxypropyldimethoxymethylsilane

[0459] ・(B) 0.4 part of polymerization initiator described in Table 2

[0460] · 24 parts of dispersion liquid containing (A) black pigment described in Table 1

[0461] ·Propylene glycol monomethyl ether acetate 10 parts

[0462] ·8 parts of cyclohexanone

[0463] 2. Manufacture and evaluation of shading f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com