Double-tube drop-irrigation cotton partition plate pot

A cotton and clapboard technology, applied in container cultivation, horticulture, botanical equipment and methods, etc., can solve the problem of not being able to understand the distribution characteristics of the root system of alternate root irrigation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with specific embodiments.

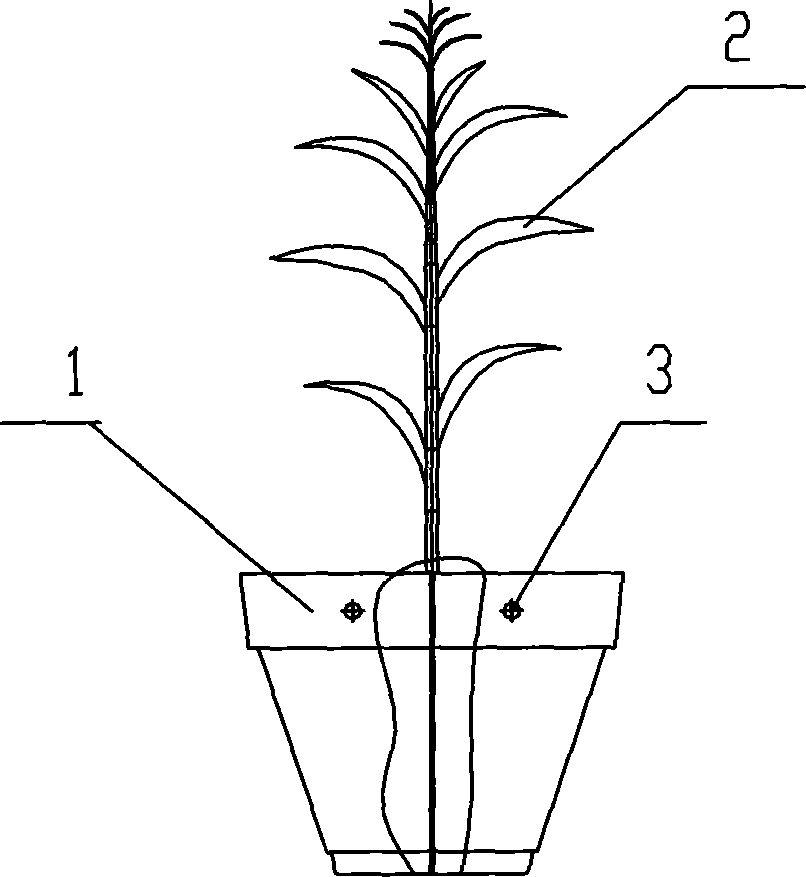

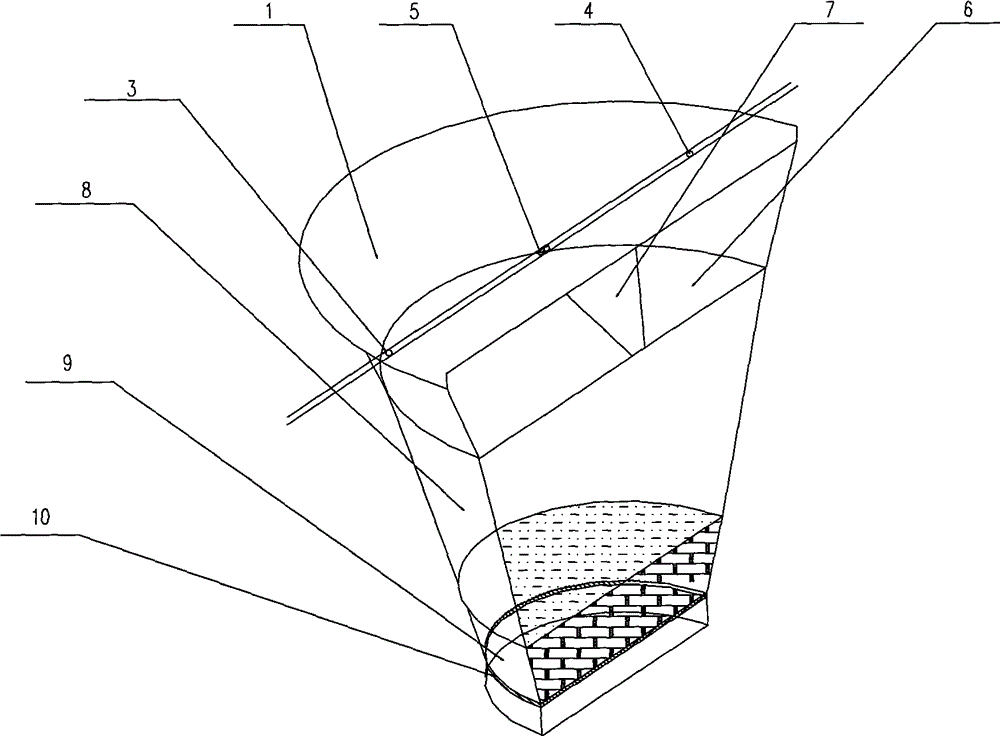

[0015] reference figure 1 with figure 2 , Double-pipe drip irrigation cotton partition pot, including plastic pot 1, built-in drip irrigation dripper 5, built-in drip irrigation capillary 4, trapezoidal gap 7, plastic partition 6, capillary hole 3, soil 8, sand and gravel 9 and filter Sand net 10, plastic partition 6 (using high-density polyethylene and polypropylene as the main raw materials, the plastic middle plate made by extrusion and compression forming, which is made into a certain shape under artificial action. It is resistant to bending and Aging, tensile, compression and tearing strength is high) is a vertical thin plate that penetrates the upper and lower sides of the plastic basin 1, which separates the water and fertilizer on both sides of the plastic partition 6. Dig a trapezoidal gap in a straight and even position called trapezoidal gap 7; put a sand filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com