Automatic cleaning device

An automatic cleaning and cleaning technology, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve problems such as inability to blow out dirt, increase production line downtime, and labor time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

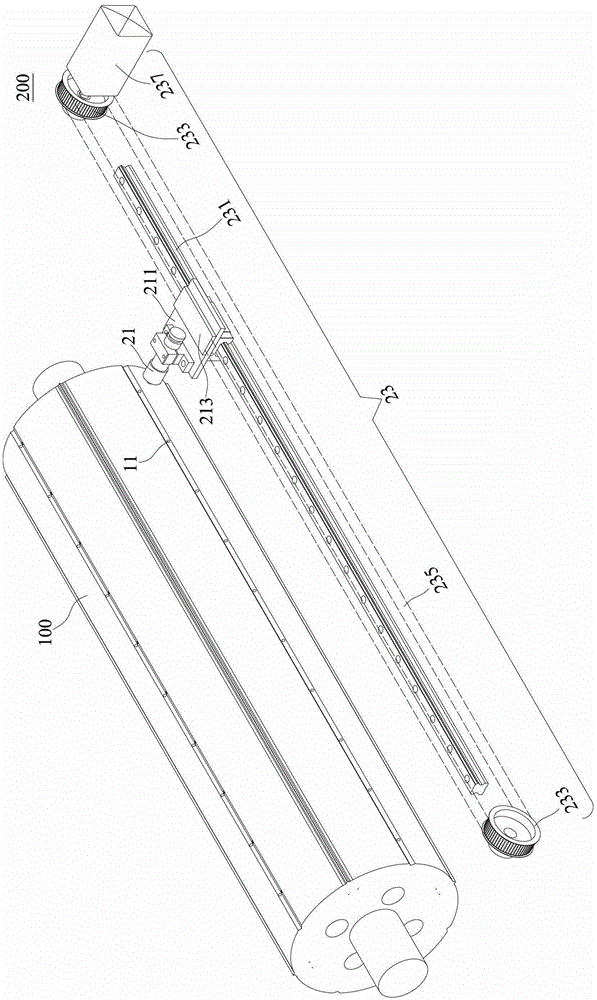

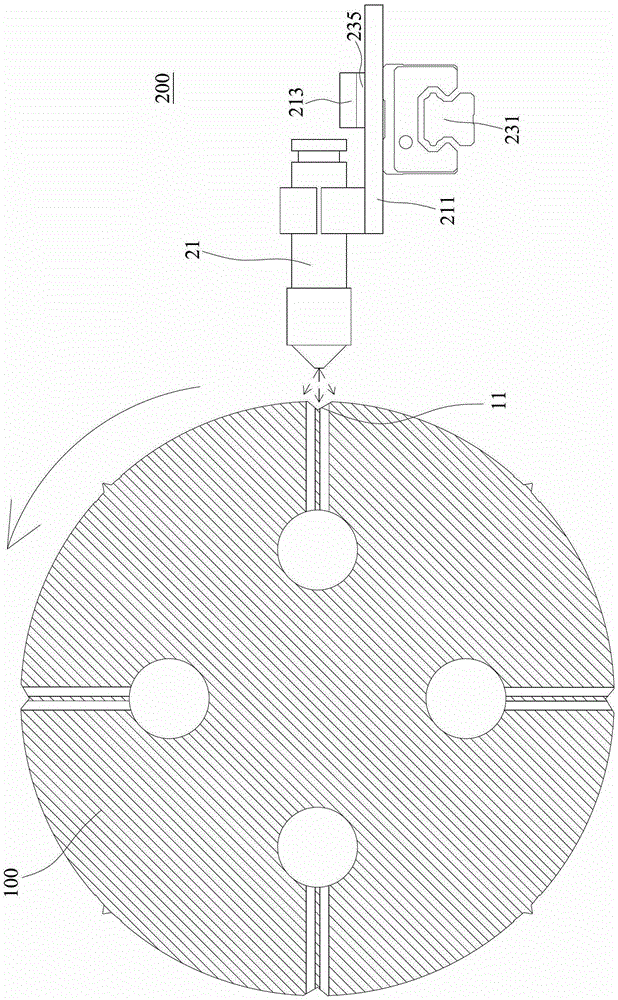

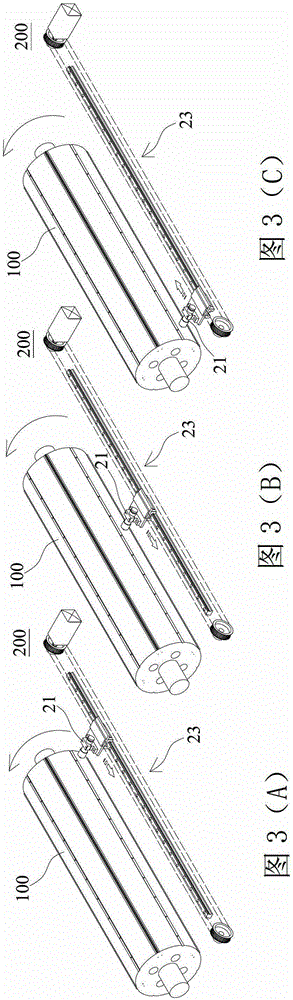

[0036] see figure 1 , figure 2 and Figure 3(A)-Figure 3(C) , is a structural perspective view and a structural sectional view of a preferred embodiment of the automatic cleaning device used to clean the suction holes of the rollers of the present invention, and a structural perspective view of the blowing device of the present invention moving beside the wheel surface of the rollers. As shown in the figure, the automatic cleaning device 200 of the present invention is used to clean a roller 100 having a plurality of suction holes 11 . The roller 100 utilizes the suction holes 11 on the wheel surface to absorb some light and soft products (such as toilet paper, cloth, film), and utilizes the rotation of the roller 100 so that these products adsorbed on the roller 100 can be on the production line Produced by transferring s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com