Mold worktable with rubber ring

A worktable and rubber ring technology, applied in the field of die stamping, can solve the problems of producing substandard products, enterprise losses, and unstable movement of the workpiece pressed by the center block of the die, so as to improve the qualified rate of products, solve the problem of wear and tear, and ensure The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with accompanying drawing:

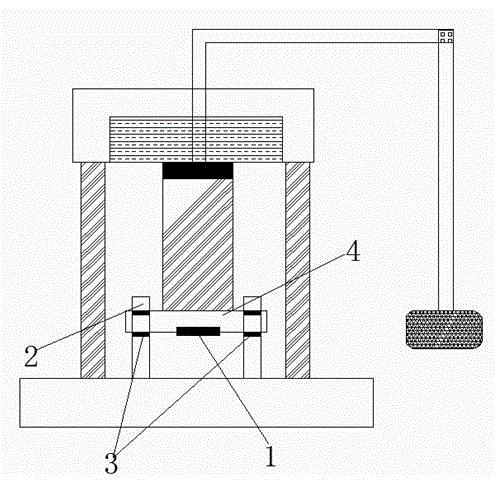

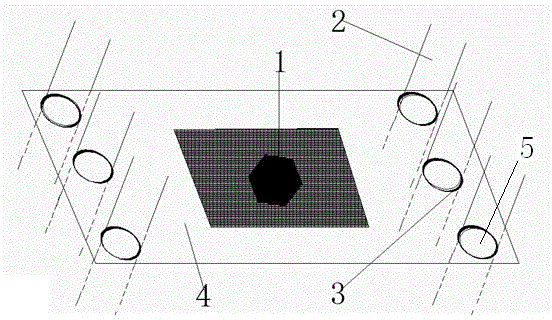

[0010] Such as figure 1 As shown, the present invention relates to a mold table with a rubber ring, which is provided with a mold center block 1, a fixed rod 2, a mold table 4, an inner hole 5, and a rubber ring 3, and is characterized in that: a mold center block 1 is provided below A mold workbench 4 is provided, and several inner holes 5 are arranged on the mold workbench 4, and the fixed rod 2 passes through the inner holes 5 to fix the mold workbench 4, and the inner hole 5 is provided with a rubber ring 3.

[0011] When the invention is in use, start the hydraulic press, the mold center block presses the workpiece downward, and the mold workbench is connected and assembled with the fixed rod through a high wear-resistant rubber ring to ensure the balance and stability of the mold when it descends, and press out qualified workpieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com