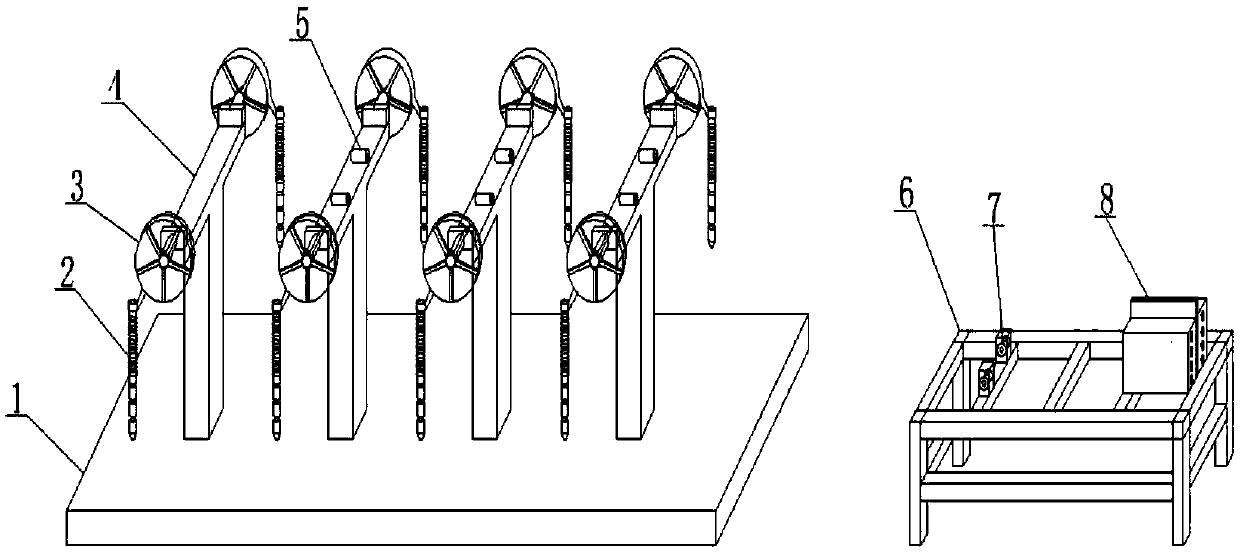

Eight-tube strain-prevention tubing pumping and feeding device

A feeding device and anti-pull technology, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of wear and tear, low efficiency and slow feeding speed, and achieve fast feeding speed and efficiency. High, structurally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

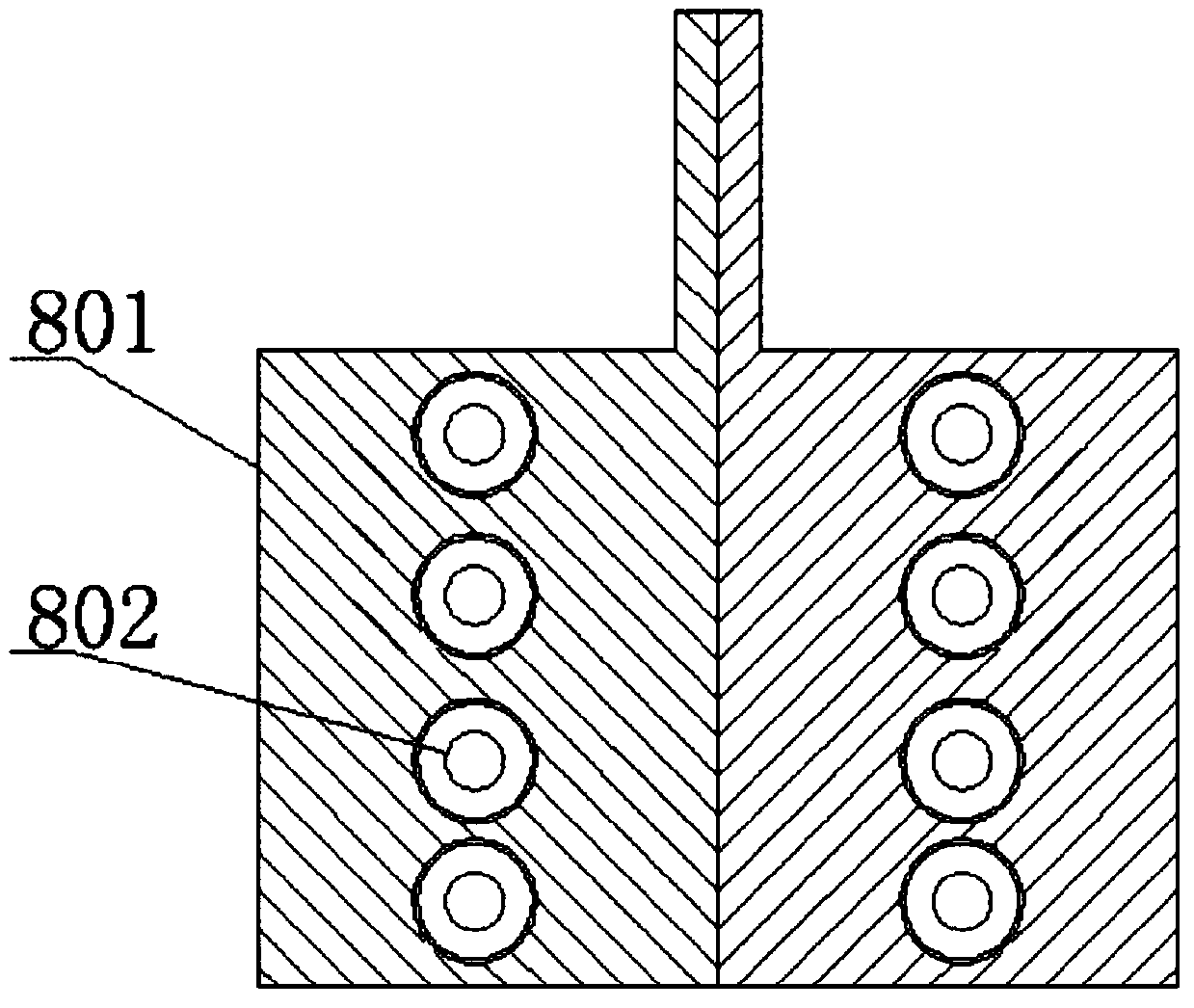

[0014] See the accompanying drawings: an eight-tube anti-strain pumping pipe material device, characterized in that it includes an anti-strain material pumping device (1-5) and an anti-strain material feeding device (6-8), the anti-strain material pumping device The device (1-5) includes eight sets of serpentine feeding rollers 2, support plates 1, four 'T'-shaped brackets 4, six guide rollers 5 and eight feeding trays 3, the four 'T'-shaped The bracket 4 is equidistantly fixed on the support plate 1, the two ends of the 'T'-shaped bracket 4 are fixed to the drawing tray 3, and the serpentine drawing roller 2 is fixed below the drawing tray 3, and the six guide rollers 5 are fixed on the 'T' On the crossbeam of the shaped bracket 4, the anti-strain feeding device (6-8) includes a bracket 6, a merge guide 8, two anti-strain pulleys 7, the support plate 1, four 'T'-shaped brackets 4 And support 6 adopts 45# steel to make, and described eight groups of serpentine feeding rollers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com