Anti-wear and slip-proof gloves

A glove and anti-slip technology, which is applied in gloves, protective clothing, clothing, etc., can solve the problems of glove wrist looseness, poor wear resistance, and objects slipping, etc., to solve the problem of wrist looseness, improve wear resistance, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

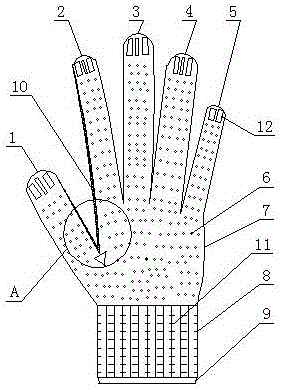

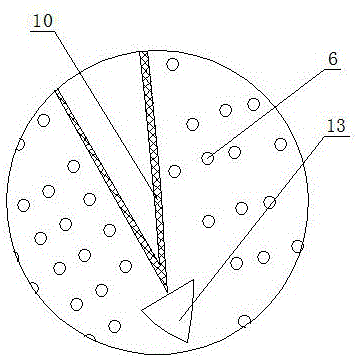

[0017] The wear-resistant and non-slip glove is composed of a glove body, which includes a wrist guard 8, a palm cover 7 and a thumb cover 1, an index finger cover 2, a middle finger cover 3, a ring finger cover 4 and a little finger cover 5 on the palm cover 7. The inner surface of the top is provided with anti-slip sheet 12 respectively, and anti-slip sheet 12 is made of PVC material and is longitudinally arranged side by side in a long strip, which can effectively improve the wear-resistant and anti-skid performance at each finger place; The palm cover 7 is provided with anti-slip lines 6, the anti-slip lines 6 are made of PVC material, have a diameter of 1-2 mm and are arranged in dots, which can effectively improve the anti-slip performance of the glove when grasping objects and reduce the risk of objects slipping; Thumb cover 1 and index finger cover 2 are respectively provided with anti-wear ribs 10 on the inner sides corresponding to them. The palm cover 7 at the bottom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com