Transmission shaft device for automobile air-conditioning compressor suction performance testing equipment

A technology for suction performance and testing equipment, applied in mechanical equipment, rigid shaft couplings, machines/engines, etc. The high-efficiency operation of the compressor production line has achieved the effect of solving the problem of wear and damage, which is conducive to promotion and good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing:

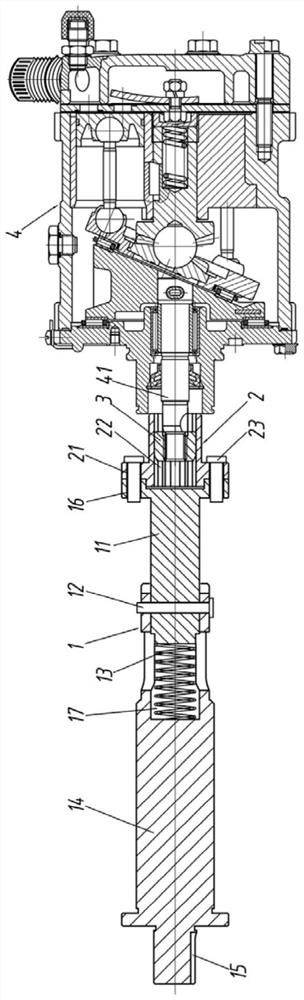

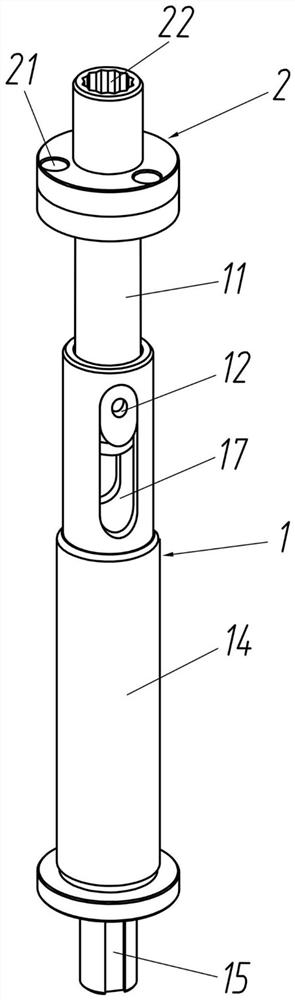

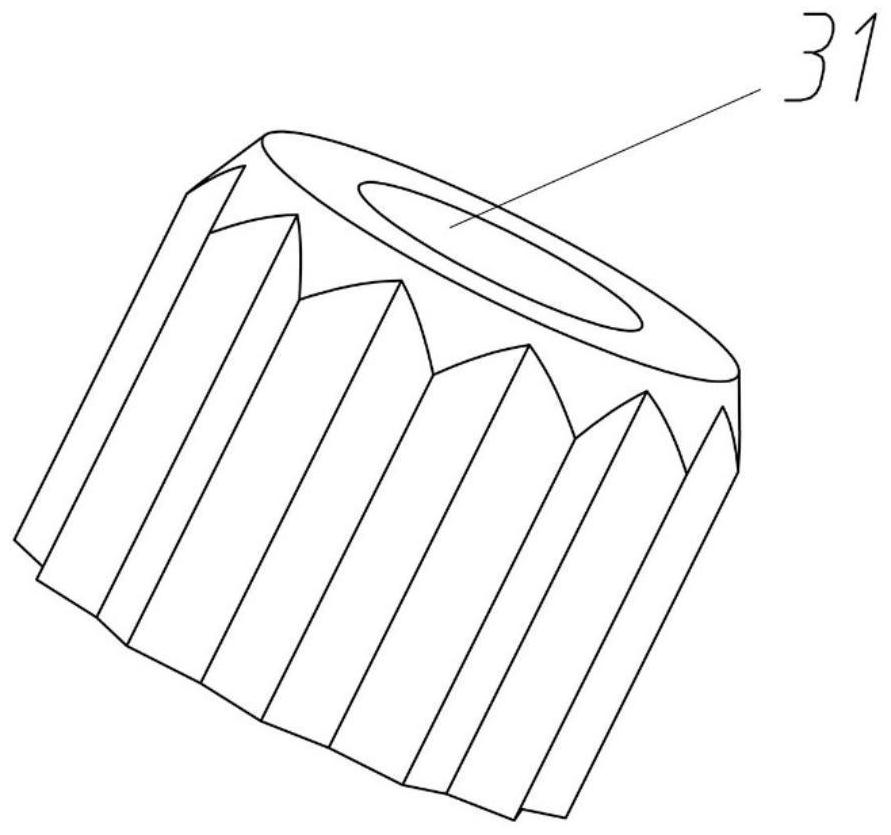

[0016] With reference to accompanying drawing: the transmission shaft device that is used for the suction performance testing equipment of automobile air-conditioning compressor in the present embodiment comprises workbench, and workbench is provided with transmission shaft structure 1, transmission head 2, twelve angle head 3, main shaft 41, the main shaft 41 is the main shaft 41 of the automobile air-conditioning compressor 4, which is installed vertically downward on the workbench, and its end is connected with the twelve-point head 3 through a threaded connection, and then through the transmission head 2 and the suction performance testing equipment The power transmission shaft structure 1 matches.

[0017] Transmission shaft structure 1 is installed vertically under the workbench, including shaft joint 11, pin shaft 12, cavity 17, spring 13, connecting shaft 14, keyway...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com