Fast clamping device in new energy automobile motor testing system

A new energy vehicle, motor testing technology, applied in workpiece clamping devices, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

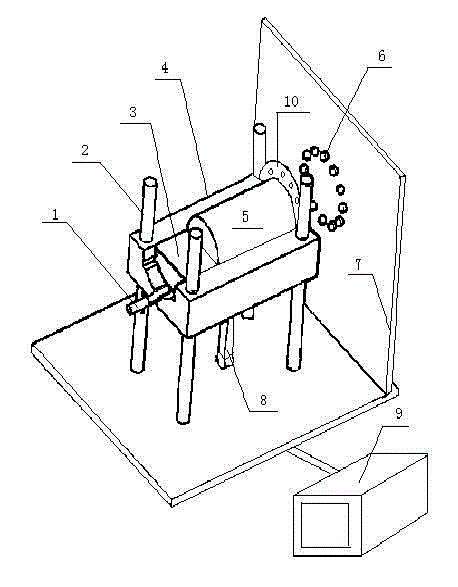

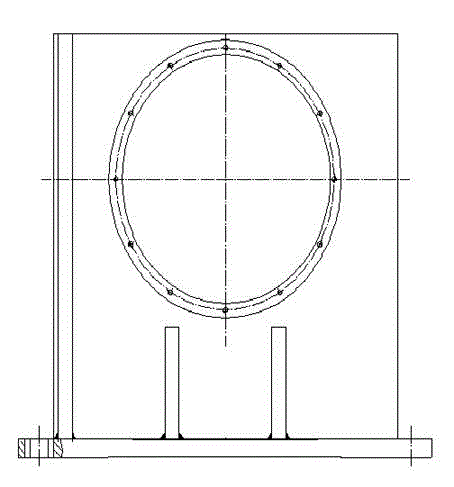

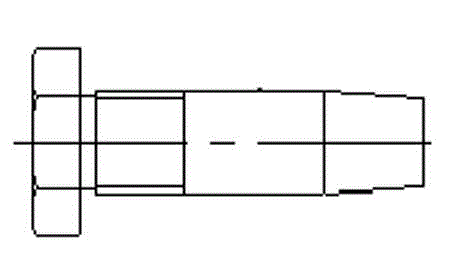

[0018] Further, the guide bolts 6 adopt a tapered structure and are provided in multiples, and are evenly distributed on the fixing bracket 7 around the circumference.

[0019] Further, a flange 10 is arranged on the fixing bracket 7 and fixed by guide bolts 6 .

[0020] Further, the lead screw pressing mechanism includes a lead screw 1 , a pressing block 3 connected to the threaded end of the lead screw 1 , and a servo motor connected to the optical axis of the lead screw 1 .

[0021] First, place the motor 5 under test in the self-centering V-shaped groove 4, and the height adjustment hydraulic cylinder 8 is driven by the hydraulic drive system 9 to adjust the height so that the center height of the motor 5 under test is equal to the center of the inner hole on the fixed bracket 7. Alignment, the left and right centers of the tested motor 5 are self-aligned by the self-centering V-shaped groove 4, and the self-centering V-shaped groove 4 is guided by four guide support colum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap