Moving parallel robot mechanism with three freedom degrees

A degree of freedom and robot technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of low running speed of the mechanism, large inertia of the execution part, and many motion pairs, so as to reduce the inertia of motion, the mechanism is simple, and the mechanism The effect of fewer joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

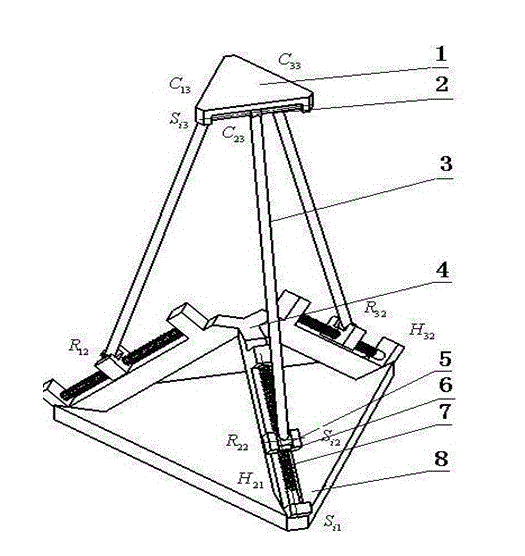

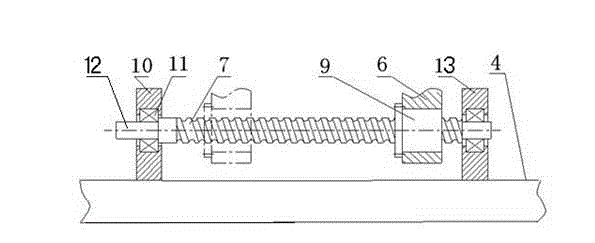

[0014] Depend on figure 1 It is known that the three-degree-of-freedom mobile parallel robot mechanism is composed of a moving platform 1, a fixed platform 8, and three branches connecting the moving platform 1 and the fixed platform 8, and the three branches are composed of three helical pairs H 7 (H 11 、H 21 、H 32 ), three rotating pairs R 5 (R 12 , R 22 , R 32 ) and three cylindrical pairs C2 (C 13 、C 23 、C 33 ), a revolving pair R5 and a cylindrical pair C2 form the axis of the helical pair H7 perpendicular to the axis of the revolving pair R5, and the axes of the revolving pair R5 and the cylindrical pair C2 are parallel to each other. The upper and lower triangles represent the dynamic platform, and each branch is kinematic chain. (i=1,2,3; j=1,2,3) indicates the axis of the joint.

[0015] In the 3-HRC three-degree-of-freedom mobile parallel robot mechanism disclosed by the present invention, the axes of the three cylindrical pairs installed on the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com