2PRU (Pseudo-Random Upstream) and CRS (Central Reservation System) spatial parallel robot mechanism

A robot and parallel technology, applied in the field of robotics, can solve the problems of high manufacturing cost, complex structure, poor workmanship, etc., and achieve the effect of easy processing and manufacturing, simple mechanism, and improved structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

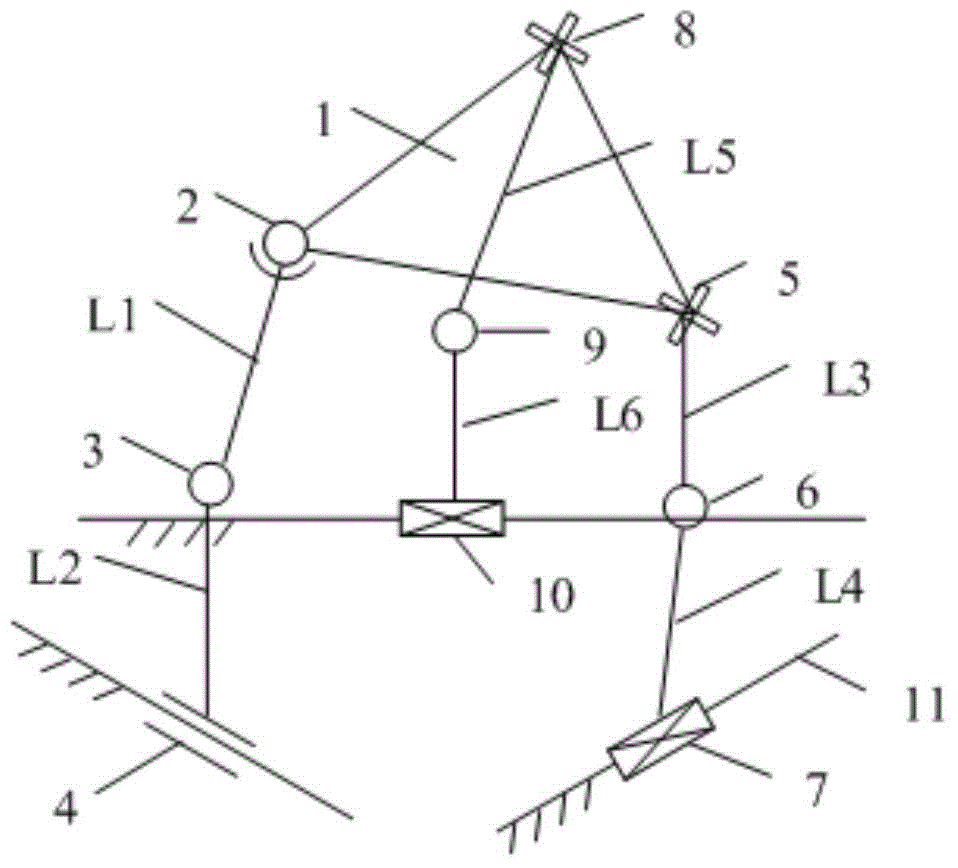

[0017] The embodiment of the present invention provides a 2PRU&CRS space parallel robot mechanism, such as figure 1 As shown, it consists of a moving platform 1, a fixed platform 11 and three branch chains connecting the above two platforms. The first branch chain and the second branch chain in the three branch chains have the same structure, and the two branch chains are from top to bottom It is composed of a universal joint pair, a rotating pair, a moving pair and the connecting rod between them. The third branch chain in the three branch chains is composed of a ball pair, a rotating pair, a cylindrical pair and The link between them consists of;

[0018] One end of the upper link L3 of the first branch chain is connected with the motion platform 1 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com