Oil separation system structure of screw air compressor

An air compressor oil and sub-system technology, used in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of cumbersome installation, increase leakage points, unfavorable installation, etc., and save labor, pipes and joints. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

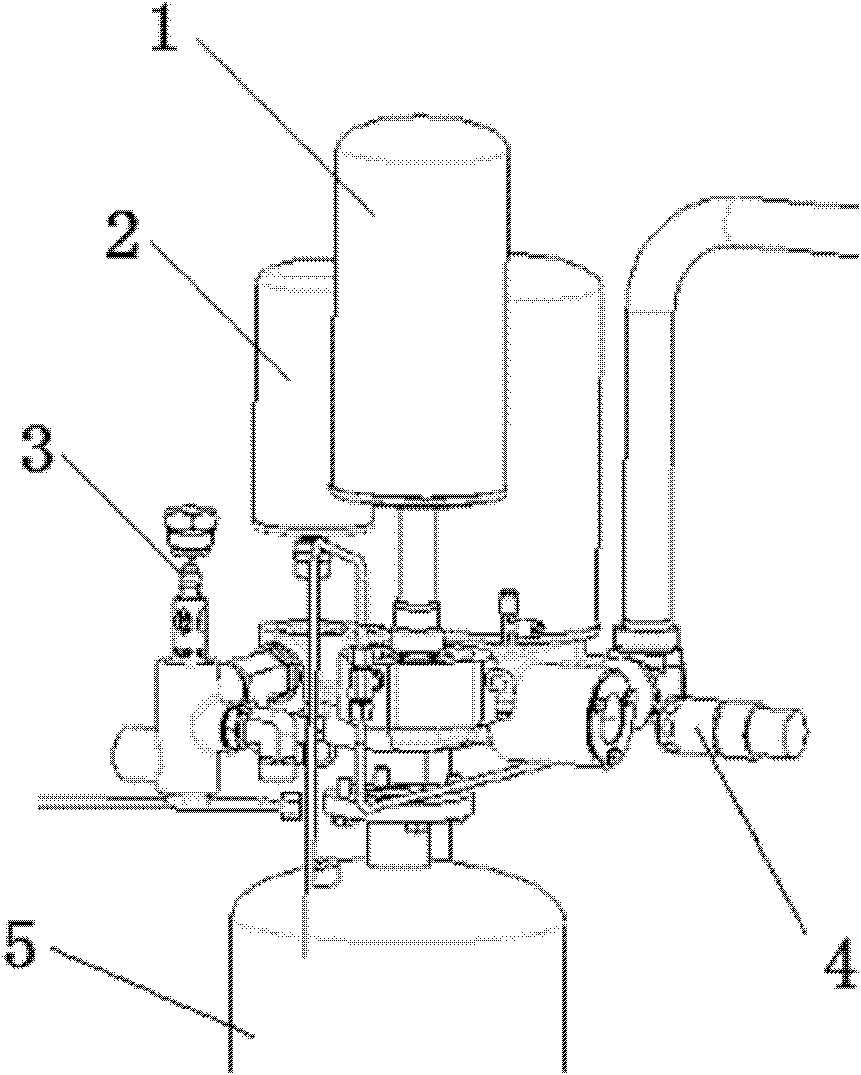

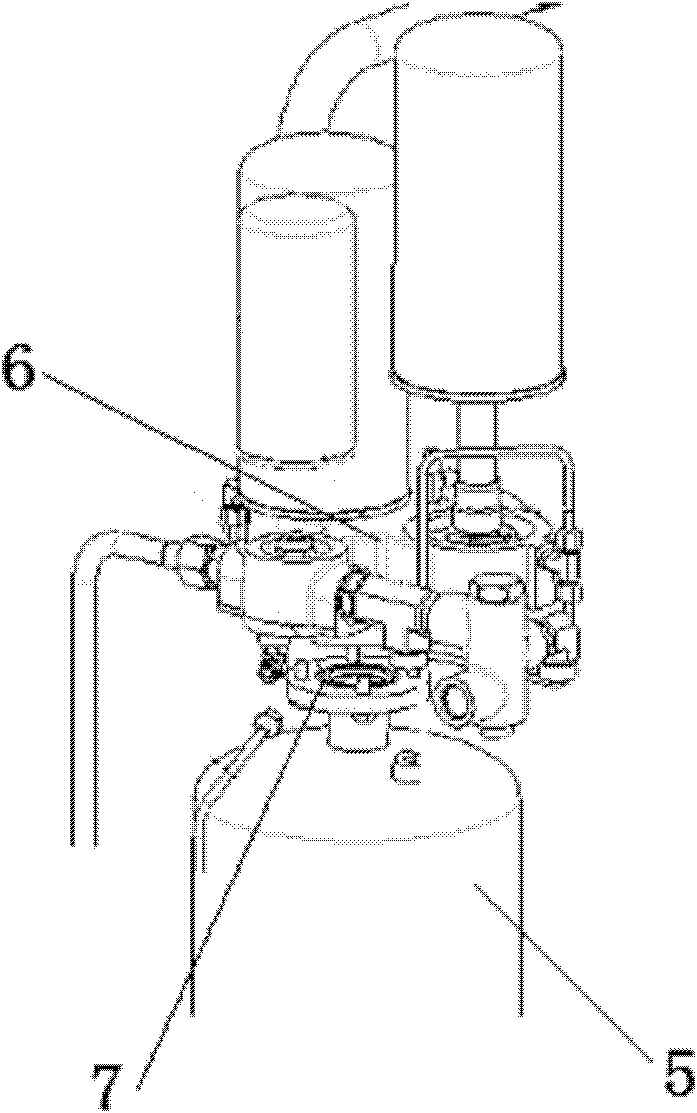

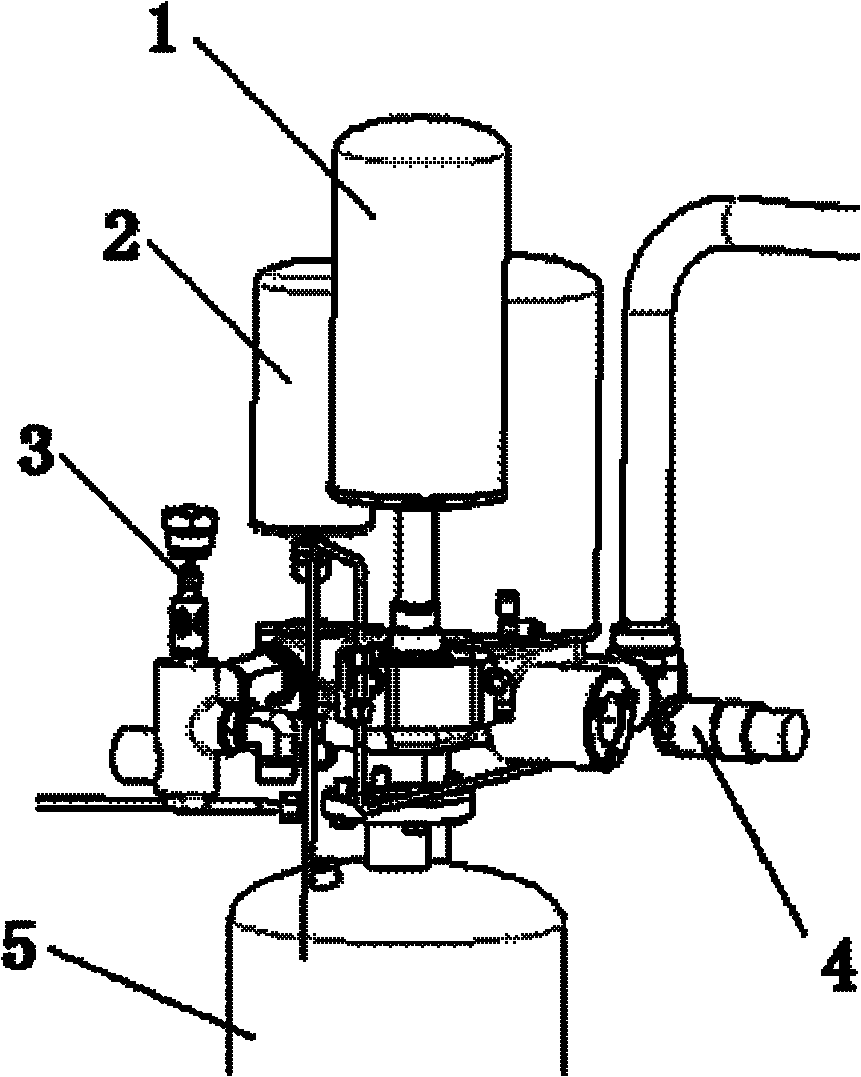

[0016] Such as figure 1 with figure 2 As shown in the figure, a combination valve 6 is included in the figure, an oil separation barrel 5 is placed under the combination valve 6, an O-ring 7 with a sealing effect is arranged at the connection between the combination valve 6 and the oil separation barrel 5, and an O-ring 7 with sealing effect is arranged on the combination valve 6. Oil separator 1, oil filter 2, the lower port of oil separator 1 and the lower port of oil filter 2 are respectively connected to combined valve 6, combined valve 6 is connected to a temperature control valve spool 3, and one side of combined valve 6 is connected to a minimum pressure valve 4.

[0017] The oil separator core 1 and the oil filter core 2 are arranged vertically and parallelly on the combined valve.

[0018] The structure of the oil separation system in this embodiment is mainly used in V series 15-37KW air compressors.

[0019] The present invention adopts an integral valve body on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com