Gamma ray density measuring system and method for minus temperature and high pressure

A gamma ray and density measurement technology, applied in the field of gamma ray density measurement system, can solve the problems of unusability, strict measurement conditions, and great influence of measurement results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

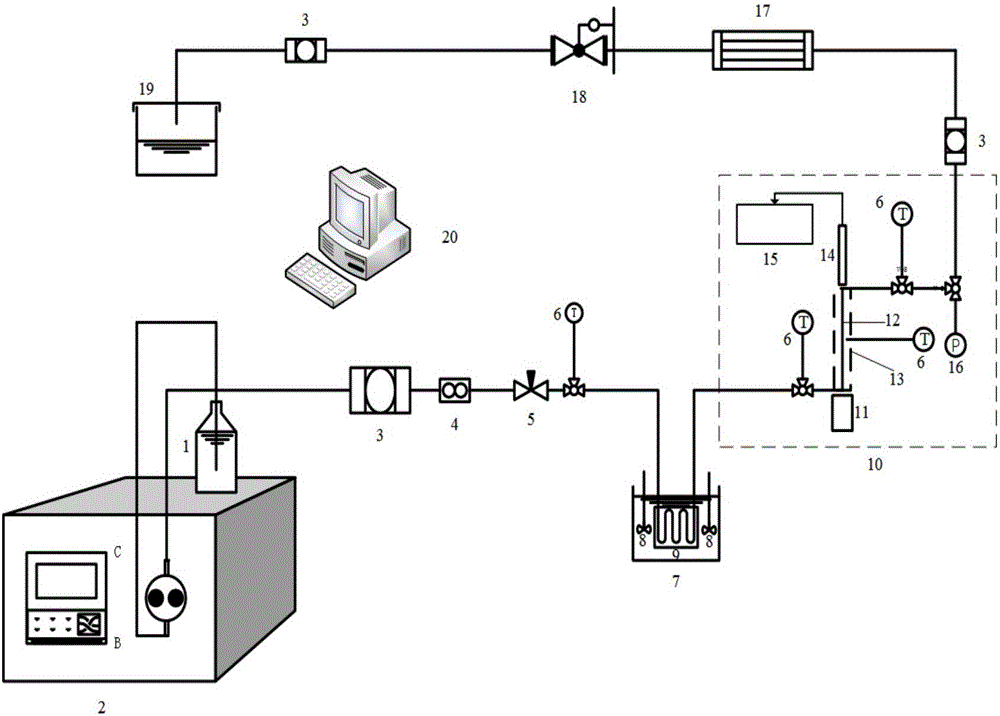

[0058] see figure 1 , a gamma-ray density measurement system for negative temperature and high pressure, including a liquid storage tank 1 for placing the fluid to be tested and a constant-flow pump 2 connected to it. The constant-flow pump 2 passes through the pipeline before the test and gamma-ray density measurement The devices 10 are connected to each other, and a filter 3, a mass flow meter 4, a regulating valve 5 and a negative temperature constant temperature tank 7 are sequentially arranged on the pipeline before the test;

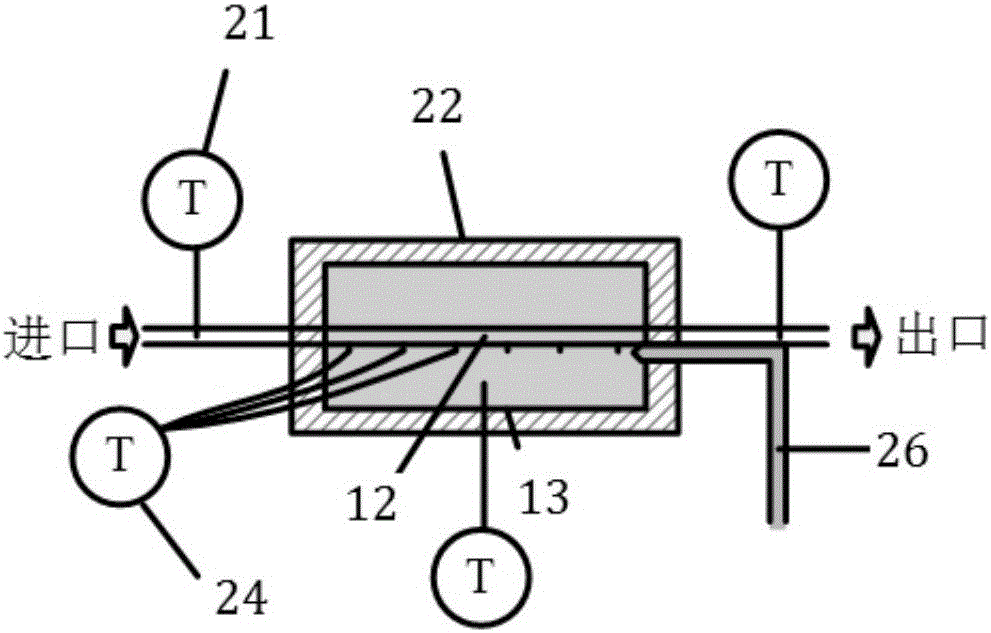

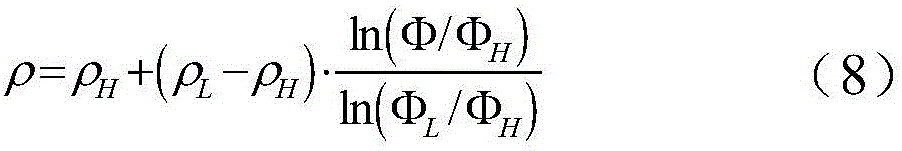

[0059] The gamma ray density measuring device 10 includes a gamma ray source 11 positioned on the same straight line, a test pipeline 12 and a receiver 14 placed in an incubator 13, a signal processing device 15 is connected with the receiver 14, and the test tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Emission intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com