Viscosity coefficient measurement method based on photoacoustic effect

A technology of viscosity coefficient and measurement method, applied in the field of physical measurement, which can solve the problems of difficulty in judging the whereabouts of the center line of a small glass tube, low accuracy, and poor repeatability of falling ball measurement time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

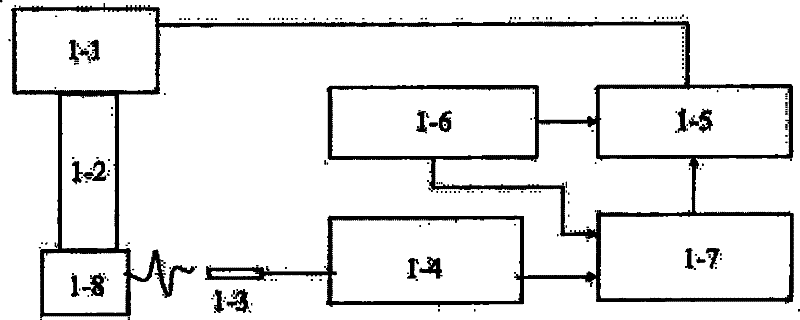

Method used

Image

Examples

Embodiment 1

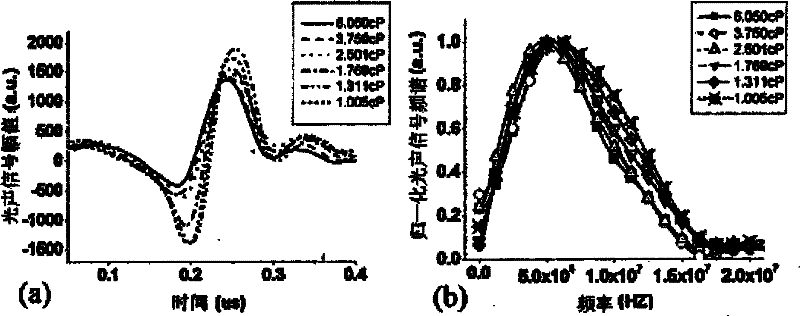

[0050] Embodiment 1. Measuring the time-domain photoacoustic signal of glycerol aqueous solutions with different viscosity coefficients:

[0051] (1) Different viscosity coefficients ξ n The liquid samples are placed in the container respectively, and the pulsed laser is focused and irradiated on the liquid sample to excite the photoacoustic signal;

[0052] (2) Using the acquisition system to record the photoacoustic signal P(t) of the liquid sample. Plotting thermoacoustic signals with Origin figure 2 (a), and calculate the thermoacoustic conversion efficiency by known parameters.

[0053] It can be seen from the figure that with the increase of the viscosity coefficient, the amplitude of the liquid thermoacoustic signal decreases, which is consistent with the change law of equation (10). Due to the effect of heat dissipation caused by viscosity, the conversion efficiency of thermoacoustic signal is significantly reduced.

Embodiment 2

[0054] Embodiment 2, measuring the frequency-domain photoacoustic signal of glycerol aqueous solution with different viscosity coefficients:

[0055] (1) Different viscosity coefficients ξ n The liquid samples are placed in the container respectively, and the pulsed laser is focused and irradiated on the liquid sample to excite the photoacoustic signal;

[0056] (2) Using the acquisition system to record the photoacoustic signal P(t) of the liquid sample. Use the acquisition system to record the photoacoustic signal of the liquid sample and use Matlab to perform Fourier transform on the recorded photoacoustic signal to obtain the spectrum of the liquid thermoacoustic signal with different viscosity coefficients figure 2 (b).

[0057] It can be seen from the figure that with the increase of the viscosity coefficient, the main frequency and bandwidth of the liquid thermoacoustic signal decrease, which is consistent with the change law of equation (10).

Embodiment 3

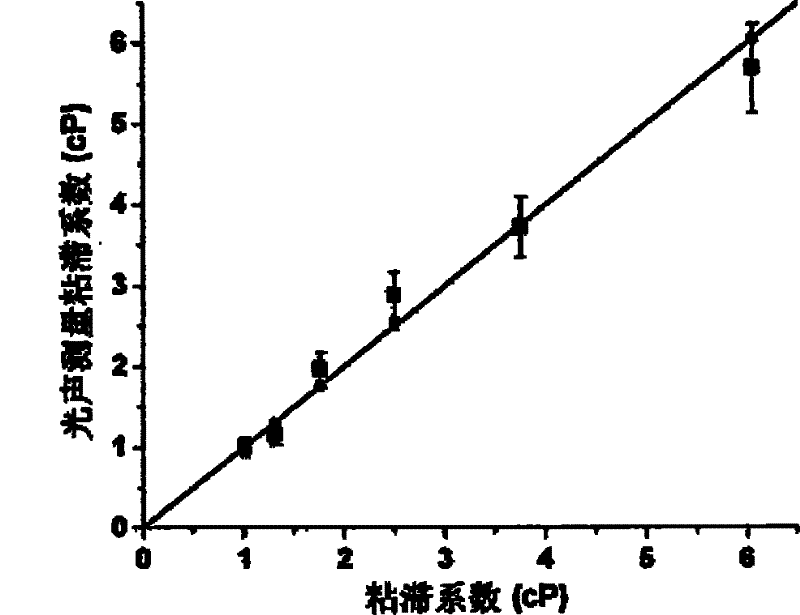

[0058] Embodiment 3, obtain the viscosity coefficient of glycerol aqueous solution with different viscosity coefficients by thermoacoustic signal frequency shift calculation:

[0059] (1) The known viscosity coefficient ξ 1 The glycerol aqueous solution is placed in a container, and the pulsed laser (continuously modulated laser) is focused and irradiated on the glycerol aqueous solution to excite the photoacoustic signal;

[0060] (2) Use the acquisition system to record the photoacoustic signal P(t) of the liquid sample, and use Matlab to perform Fourier transform on the recorded photoacoustic signal;

[0061] (3) Extract the main frequency or bandwidth ω of the photoacoustic signal 1 , according to k 1 = ω 1 / c s1 Get the wavelength k 1 ; The photoacoustic pressure function P(t) is obtained by ultrasonic transducer detection, according to the main frequency of the photoacoustic signal in the following photoacoustic signal frequency domain expression equation The rela...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com