Treatment-free rubber roll for air vortex spinning

A vortex spinning, treatment-free technology, applied in the direction of drafting equipment, etc., can solve the problems of shortened service life, high production cost, difficult to dissipate heat, etc., and achieve the effect of prolonging service life, improving rigidity and easy heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

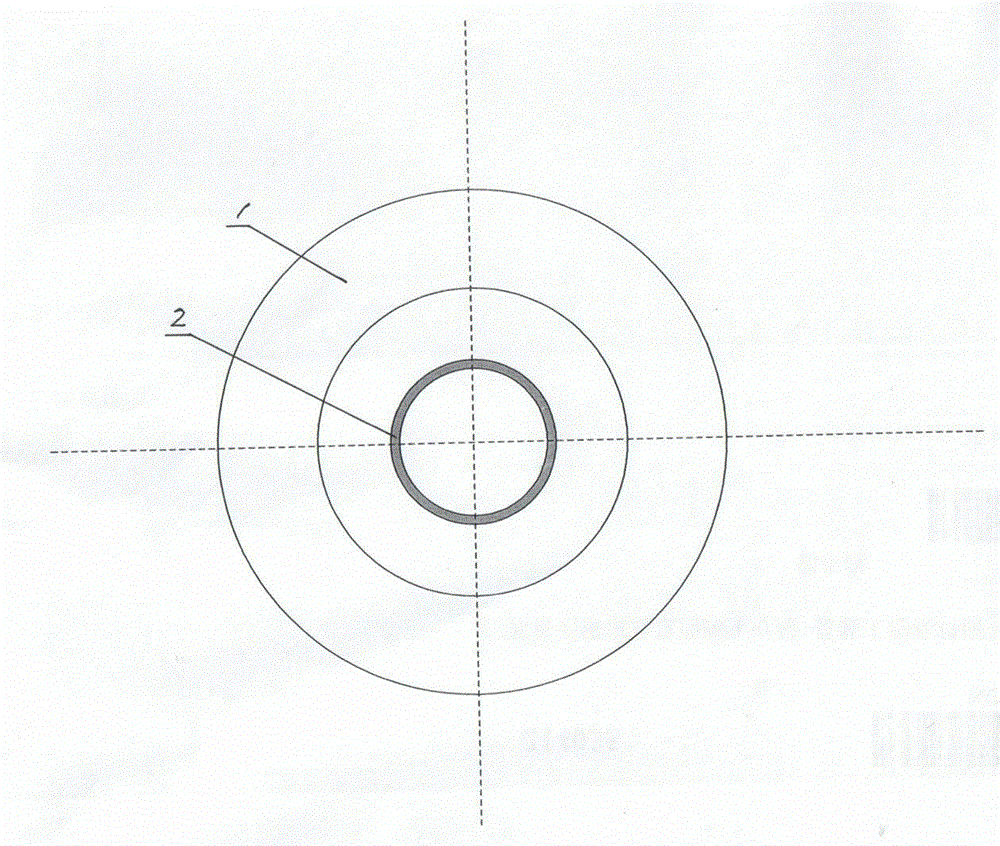

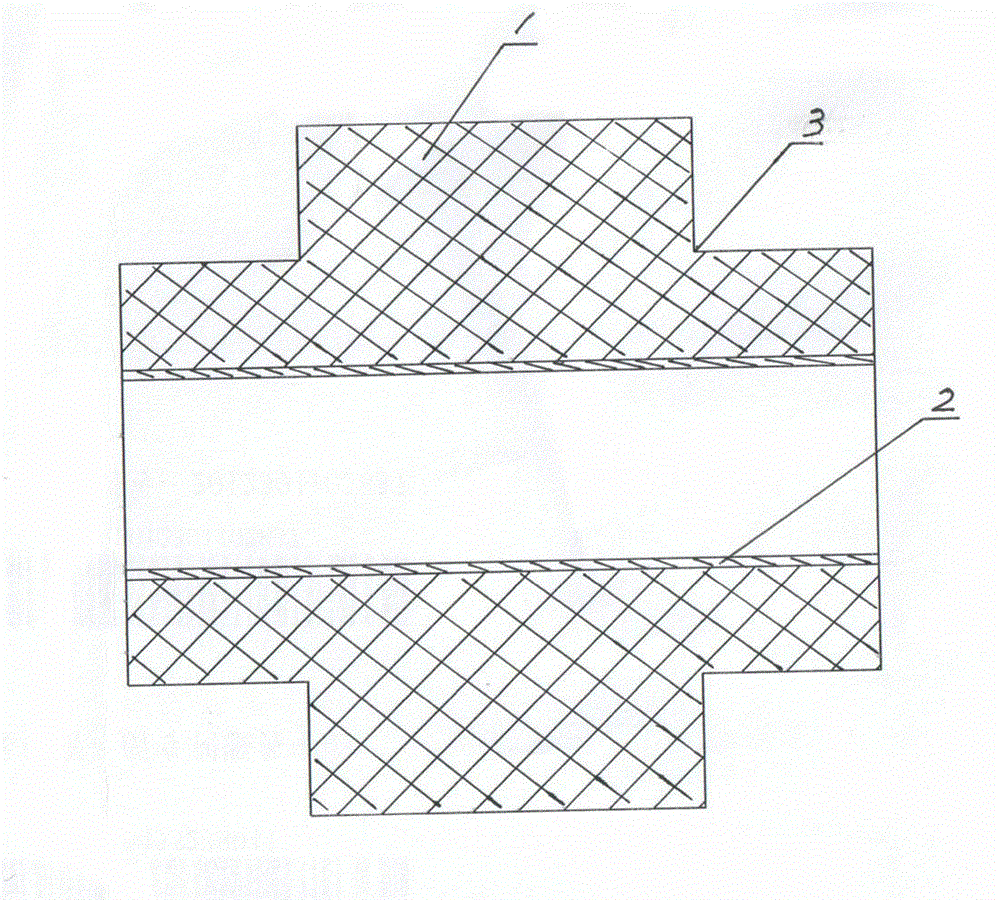

[0013] Such as figure 1 and figure 2 As shown, the treatment-free rubber roller for vortex spinning of the present invention includes a roller body 1, and the roller body 1 is a short circular rubber tube, in which an aluminum bush 2 is arranged, and the aluminum bush 2 and the roller body 1 tightly compounded together. In the state of use, the treatment-free rubber roller for eddy current spinning of the present invention is sheathed on the bearing. When cooperating with the bearing, only the aluminum bush 2 is in contact with the bearing, as long as the inner diameter of the aluminum bush 2 is a few wires smaller than the bearing, the two can be fitted together in an interference shape, so that the present invention and the bearing The bonding force is improved, and it is not easy to escape from the bearing. Since there is an aluminum bush 2 inside the roller body 1, only the aluminum bush 2 is in contact with the bearing in the process of combining with the bearing, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com