Water trough drainer and water trough drainer deodorization method

A technology for sinks and sinks, which is applied in the field of deodorization of sinks and sinks. It can solve the problems of easy accumulation of food residue and water mixture, large space occupied by water in the sink, and poor drainage of S-bend pipes, etc., so as to avoid pipes. The effect of crossing, simple pipeline and simple overflow pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

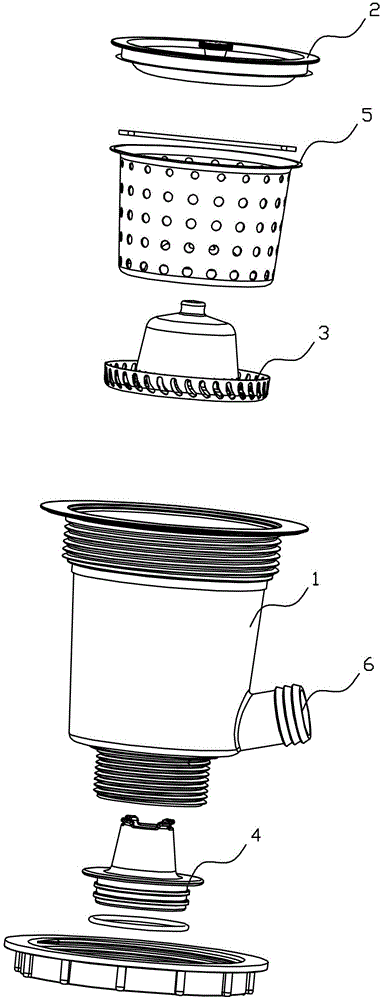

[0063] A sink drainer such as figure 1 As shown, it includes a drain body 1, a drain end cover 2, a water seal cover 3, a water seal pipe 4, and a water leakage basket 5. The side wall of the drain body 1 is provided with an overflow port 6 for connecting with the overflow pipe 12 connected. The bottom of the drain body 1 is provided with a water outlet; the inner bottom of the drain body 1 at the drain is provided with a water seal structure for forming a water seal at the inner bottom of the drain body 1 at the drain. The implementation effect diagram is as follows Figure 16 As shown, the sink drainer 14 of the present invention is installed at the bottom of the sink 13 for deodorizing the sink 13 on the sink drainer 14 . The water flows out from the water tank drainer 14 and is directly drained through the water outlet pipe 11, no S-shaped water trap or a deodorizing bottle are required to realize the deodorizing function.

[0064] The water seal structure includes a wa...

Embodiment 2

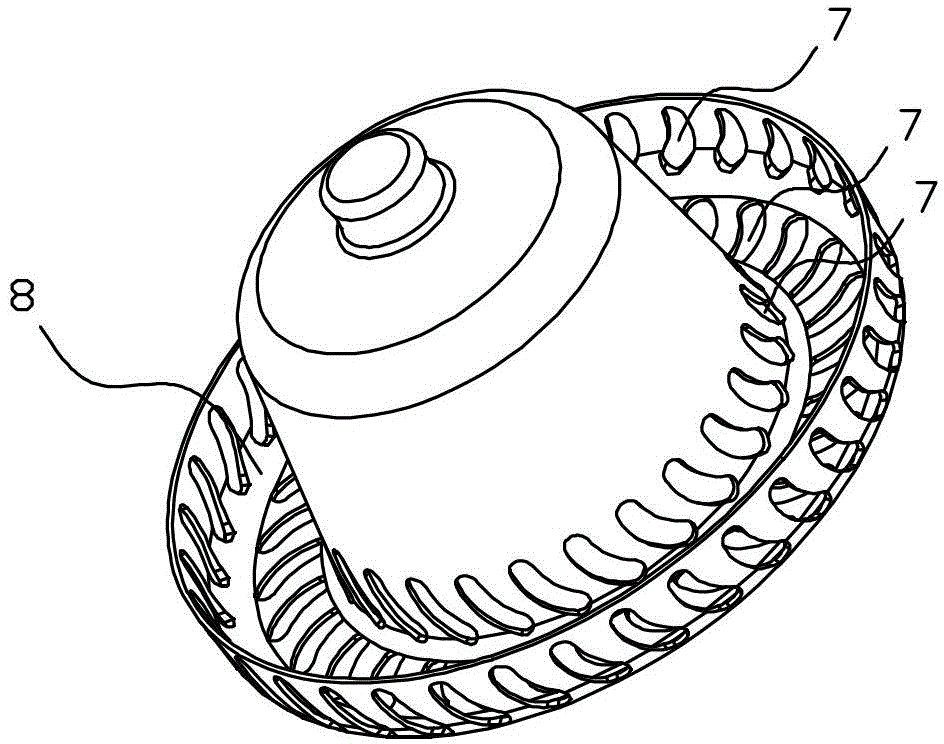

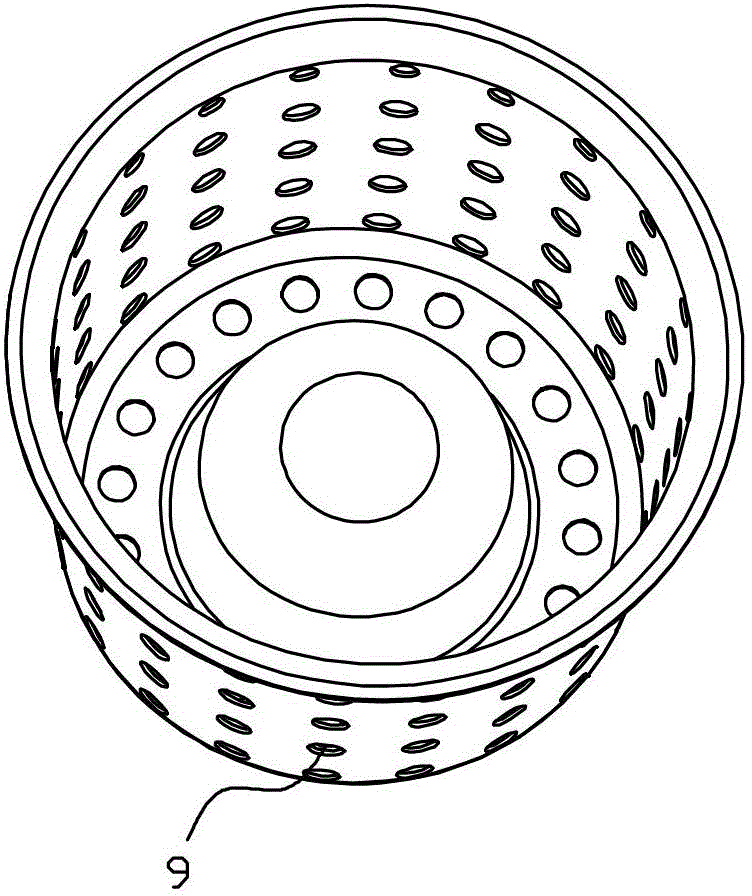

[0071] Such as Figure 7 The shown sink drain includes a drain body 1, a drain end cover 2, a water seal cover 3, a water seal pipe 4, and a water leakage basket 5. An overflow port 6 is provided on the side wall of the drain body 1 for Link to overflow pipe 12. Such as Figure 8 , Figure 9 , Figure 10 As shown, the water sealing cover 3 and the water leakage basket 5 are connected as an integrated structure. In this embodiment, the water sealing cover 3 is a cover-like structure extending outward from the bottom of the water leakage basket 5 . The bottom of the water leakage basket 5 is inwardly recessed to form the upper half of the cover-like structure of the water seal cover 3, and the bottom of the water leakage basket 5 protrudes outwards to form the lower half of the cover-like structure of the water seal cover 3. Another way of realization: the independently formed water seal cover 3 can also be welded or riveted on the bottom of the water leakage basket 5 .

[...

Embodiment 3

[0075] Such as Figure 12 , Figure 13 As shown, the water seal cover 3 and the leaky basket 5 are connected as an integrated structure. In this embodiment, the water seal cover 3 is a cover-like structure with the bottom of the leaky basket 5 sunken inward, and the bottom of the leaky basket 5 is sunken inward to form a water seal. The cover-like structure of cover 3. Such as Figure 14 As shown, the cover-shaped water seal cover 3 of the recessed part is a closed cover-shaped structure, and the bottom surface of the water leakage basket 5 is lower than the height of the water inlet 10 of the water seal pipe 4 . All the other parts are identical with embodiment 2.

[0076] The technical solution of the sink drainer of the present invention is realized based on a drainer deodorization method: a water seal is formed at the position of the drain outlet at the inner bottom of the drainer body 1 for deodorizing the sink 13 on the sink drainer 14 .

[0077] The realization of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com