Steel ring beam structure of steel plate silo

A beam structure and silo technology, applied in the field of steel ring beam structure, can solve the problems of high welding technology requirements, bulky steel ring beam structure, reduced welding strength, etc., to reduce the difficulty of installation and construction, stable and reliable structure, and convenient The effect of making and installing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

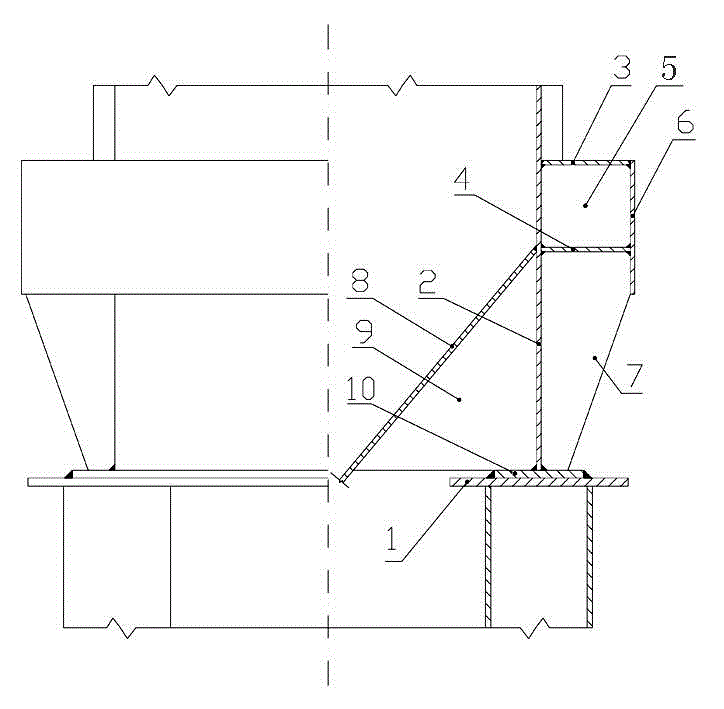

[0008] Such as figure 1 As shown, the steel ring beam structure of the steel plate silo of the present invention includes an annular backing plate 10 welded on the upper surface of the supporting steel column top plate 1, and a silo 2 whose bottom edge is welded on the upper surface of the annular backing plate 10. The outer peripheral surface of the silo 2 is welded with upper and lower annular reinforcing plates 3 and 4 at intervals, and the height of the lower annular reinforcing plate 4 is equal to the upper edge of the conical lower hopper arranged in the silo 2; Between the lower annular reinforcement plates 3 and 4, a plurality of vertical plates 5 are uniformly welded at radial intervals, and the outer edges of the upper and lower annular reinforcement plates 3 and 4 are welded with annular vertical plates 6, and the annular vertical plates 6 The lower edge of the lower edge extends to below the lower annular reinforcing plate 4; a plurality of reinforcing vertical pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com