A fuel cell flow field plate and fuel cell

A fuel cell and flow field plate technology, applied in fuel cells, fuel cell parts, circuits, etc., can solve problems such as not considering the timely discharge of water, achieve good power generation performance, and reduce resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

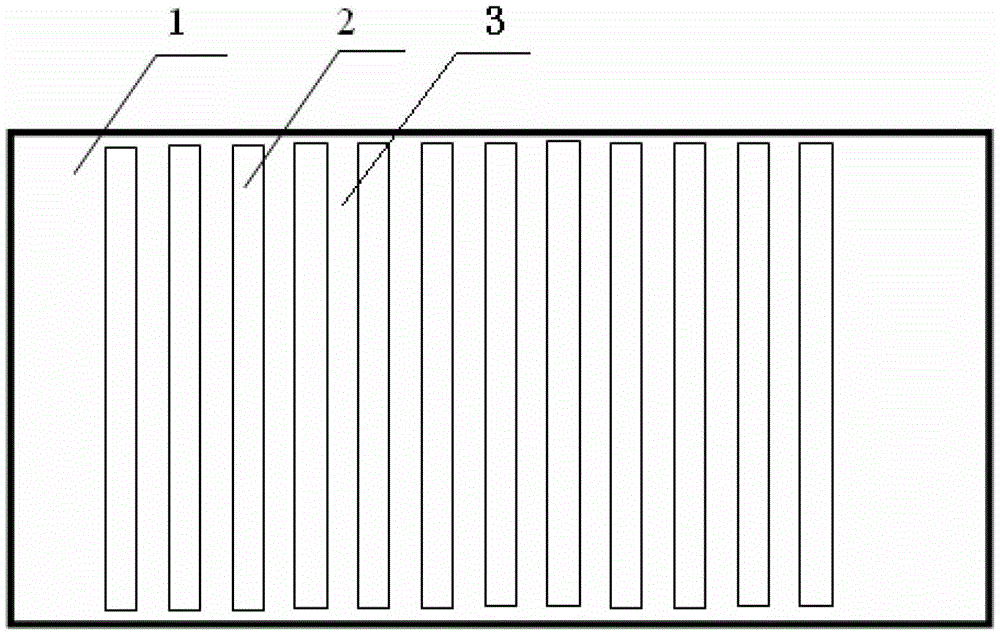

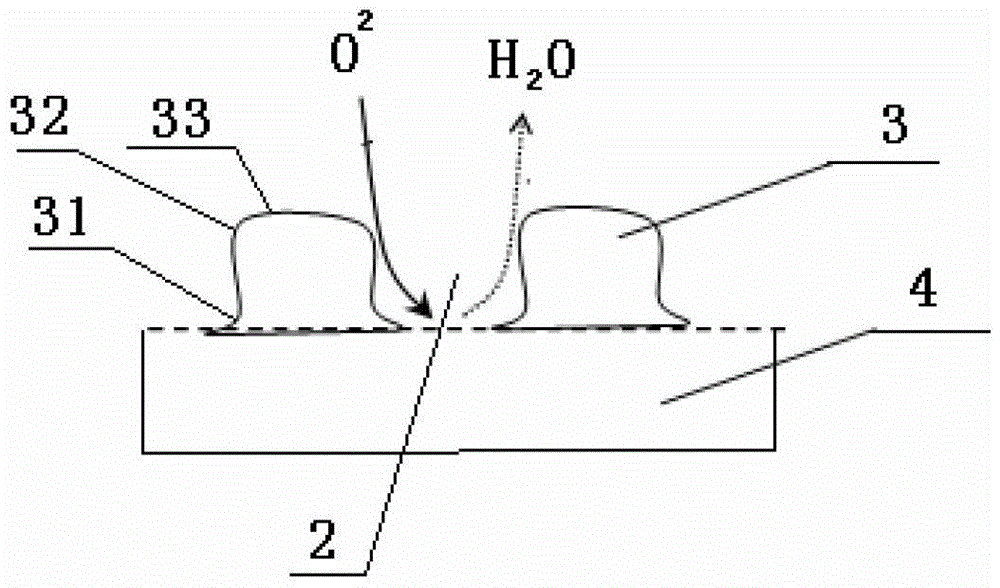

[0018] Such as figure 1 , 2 As shown, a fuel cell flow field plate includes a substrate 1 with a plurality of flow field channels 2, one end of the substrate 1 is bonded to the battery plate 4, the flow field channels 2 are arranged in parallel, and the flow field channels 2 are opened on the substrate 1 The part between the adjacent flow field channels 2 is the flow field skeleton 3; the end of the flow field skeleton 3 and the battery plate 4 is provided with a circular arc transition part 31, and the arc transition part 31 is connected to the flow field channel. 2 protrudes inside, and the end of the flow field frame 3 away from the battery plate is provided with a chamfer 32; the flow field frame 3 has a contact surface with the battery plate and an exposed surface in contact with the fluid, and the exposed surface is covered with a hydrophobic layer 33 .

[0019] The contact angle between the hydrophobic layer 33 and water is greater than 60 degrees. This contact angle...

Embodiment 2

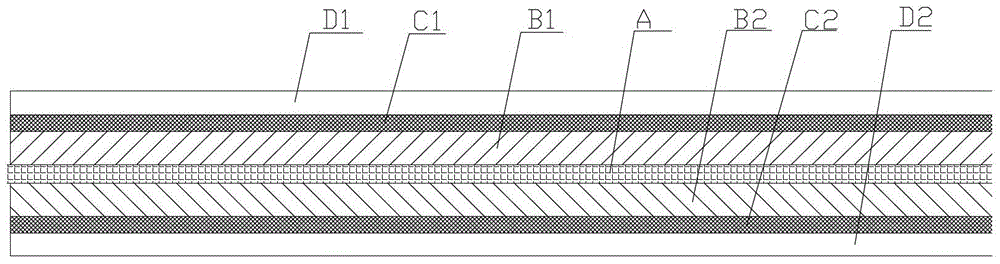

[0027] Such as Figure 1-3 As shown, a fuel cell includes a proton exchange membrane A, a battery anode plate B1 and a battery cathode plate B2 respectively arranged on both sides of the proton exchange membrane, flow field plates C1, C2 and battery splints D1, D2, each pole plate Connect a flow field plate, and each flow field plate is connected to a battery splint; the flow field plates C1 and C2 include a substrate 1 with multiple flow field channels 2, one end of the substrate 1 is attached to the battery plate, and the flow field channels 2 are arranged in parallel , the flow field channel 2 is a through groove opened on the substrate 1, and the part between the adjacent flow field channels 2 is the flow field skeleton 3; the end of the flow field skeleton 3 and the battery plate is provided with a circular arc transition part 31, The arc transition part 31 protrudes into the flow field channel 2, and the end of the flow field frame 3 away from the battery plate is provid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com