Instant type water boiler

A water boiler and water tank technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of mixing cold water and boiling water (yin and yang water, incapable water, and easy scaling, etc.) It is not easy to have quality problems and the effect of hot water health and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

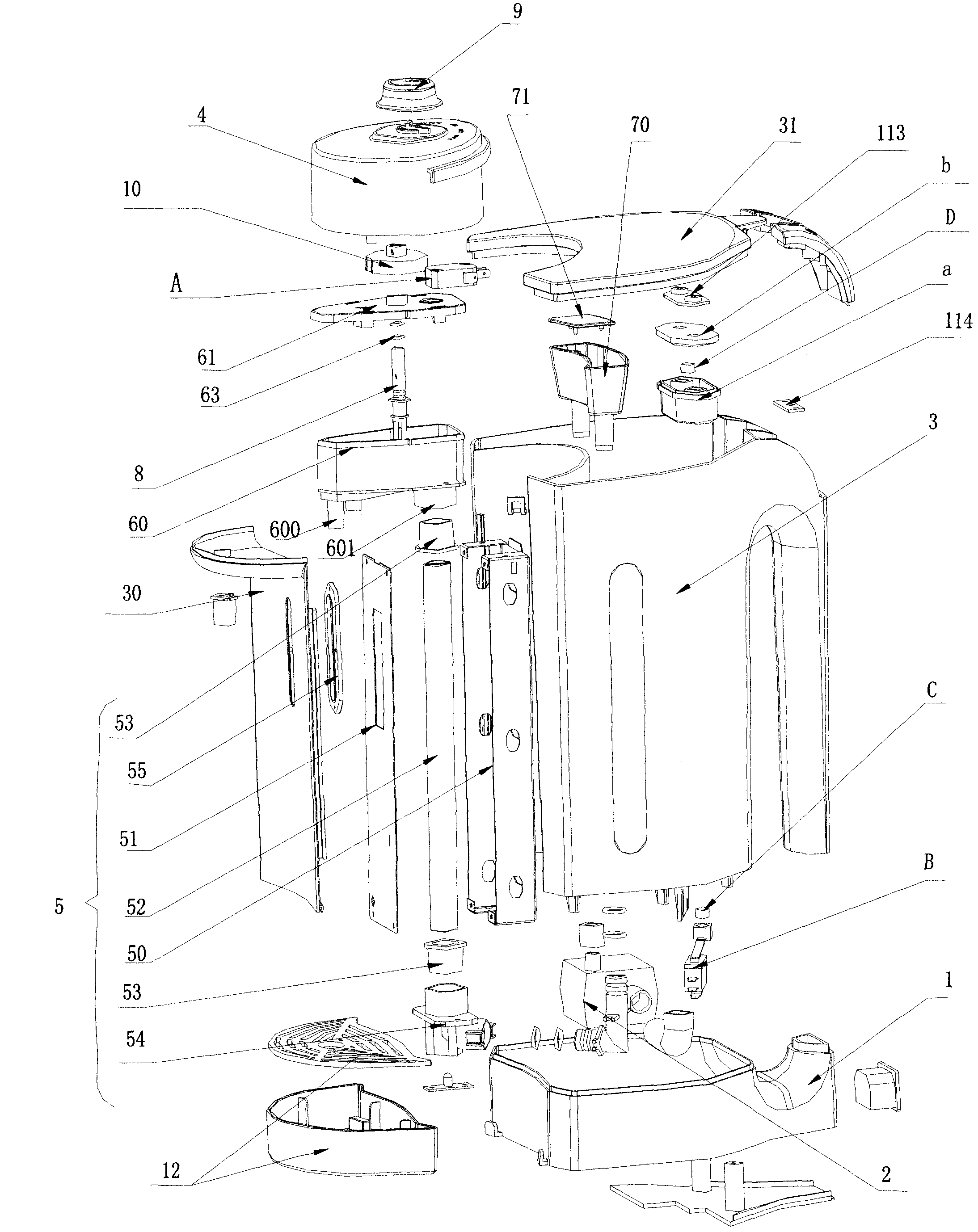

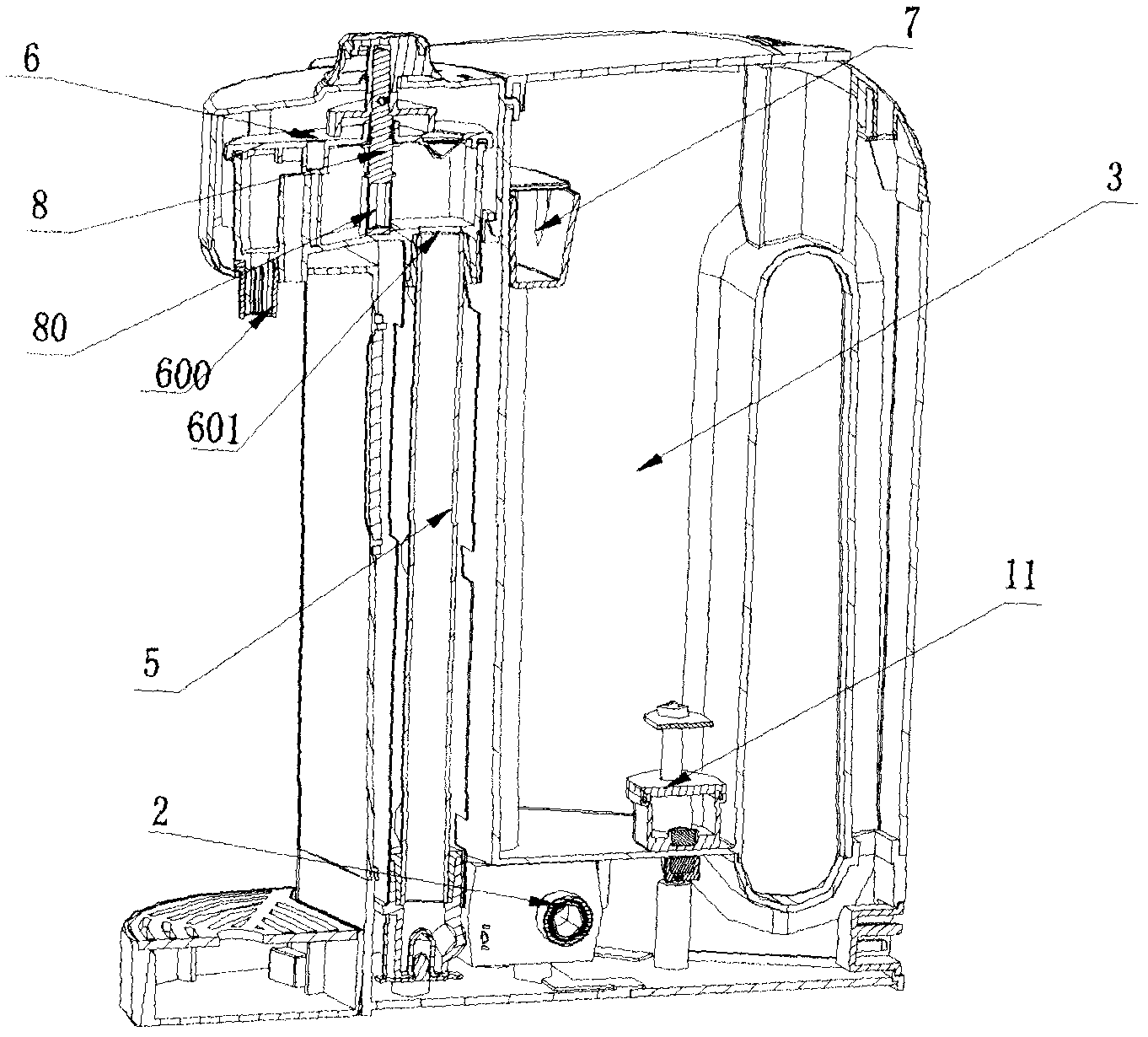

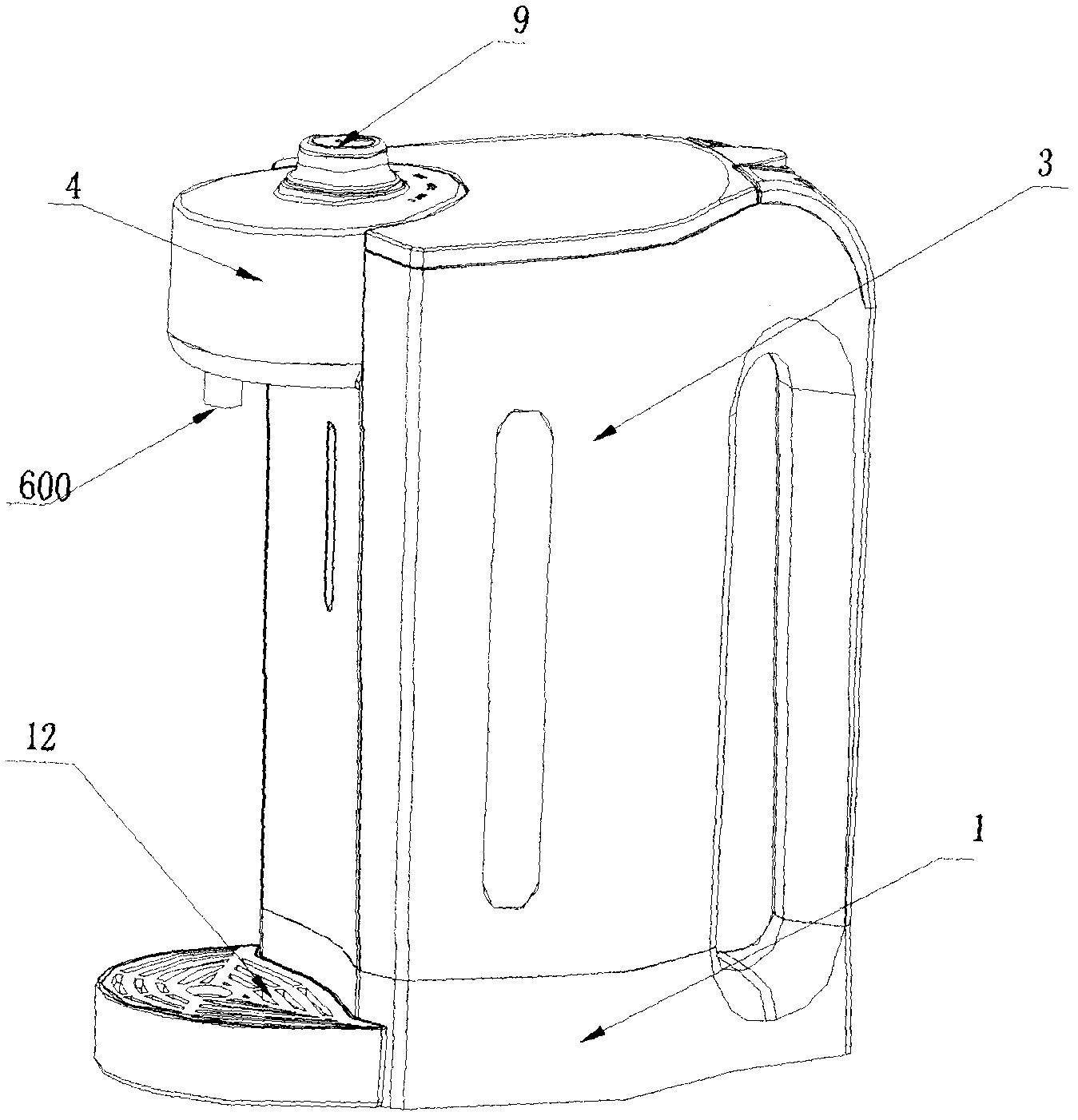

[0024] Such as Figure 1 to Figure 7 As shown, the instant water boiler includes a base 1, a water pump 2, a water tank 3 and a water outlet control panel 4. The water pump 2 is installed in the base 1 on the lower side of the bottom of the water tank 3, and the water outlet control panel 4 is installed outside the upper end of the water tank 3. side, a heating element assembly 5 is installed on the rear side of the water tank front plate 30 on the lower side of the water outlet control panel 4; The front end of the bottom of the temperature control box 6 is provided with a water outlet, and the top of the water tank 3 is installed at the position corresponding to the outer boiling water temperature control box 6. A bridging water tank 7 is installed to supply water to the heating element assembly 5 using the "U"-shaped tube principle. The water pump 2 in the base 1 The water in the water tank 3 is continuously supplied to the bridging water tank 7 through the pipeline, and a ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap