Liquid stirring device

A technology of stirring device and liquid, which is applied to household appliances, applications, kitchen utensils and other directions, can solve the problems of troublesome production process, inconvenient cleaning, difficult cleaning of dirt, etc., achieves simple processing technology, improves work efficiency, and has a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The liquid stirring device of the present invention is suitable for stirring various liquids.

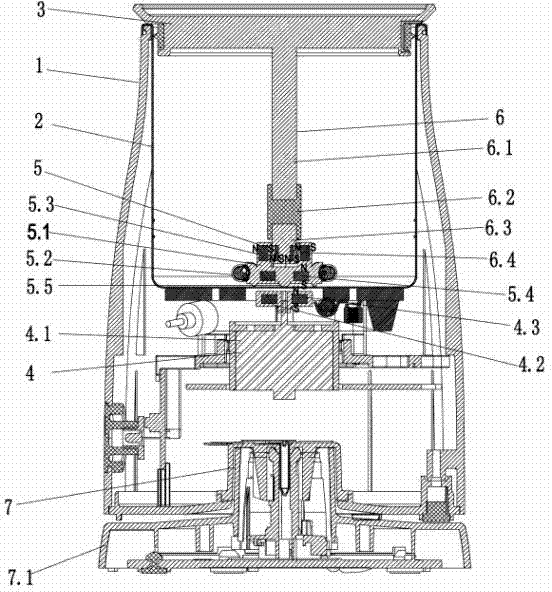

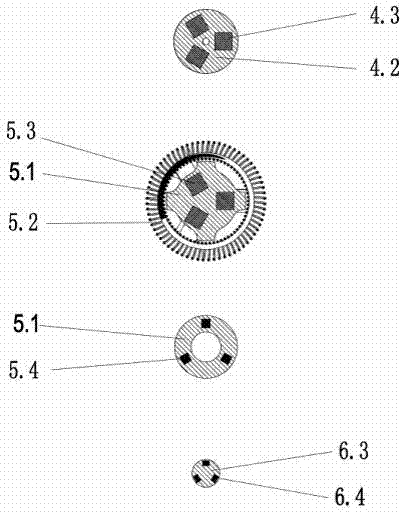

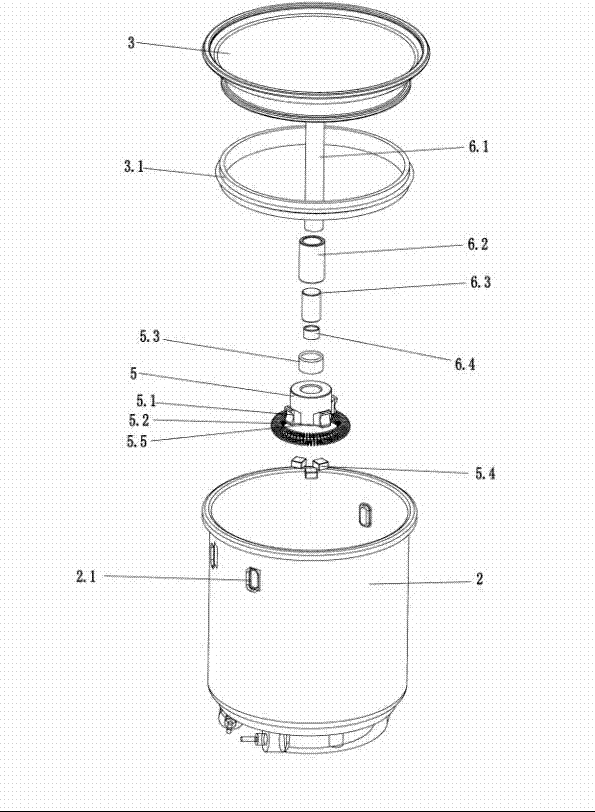

[0031] refer to figure 1 , figure 2 , image 3 , Figure 4 , the preferred embodiments of the liquid stirring device of the present invention will be described in detail below.

[0032] The liquid stirring device in this embodiment includes a housing 1, a container 2, a container cover 3, a driving device 4, a suspension device 6, and a stirring head 5, the driving device 4 is below the container 2, and the suspension device 6 And the stirring head 5 is inside the container 2 , the stirring head 5 is positioned inside the container 2 by the suspension device 6 .

[0033] In this embodiment, there is a stirring head spring 5.2 on the stirring head 5, which is used to stir the liquid to foam. There are different designs depending on the firmness of beans, fruits or other solid substances.

[0034] In this embodiment, the upper end of the suspension device 6 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com