Water filter apparatus and washing method thereof

A water filter and filter technology, applied to chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of wasting manpower and time, cumbersome operation, etc., and achieve labor and time saving, low cost and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

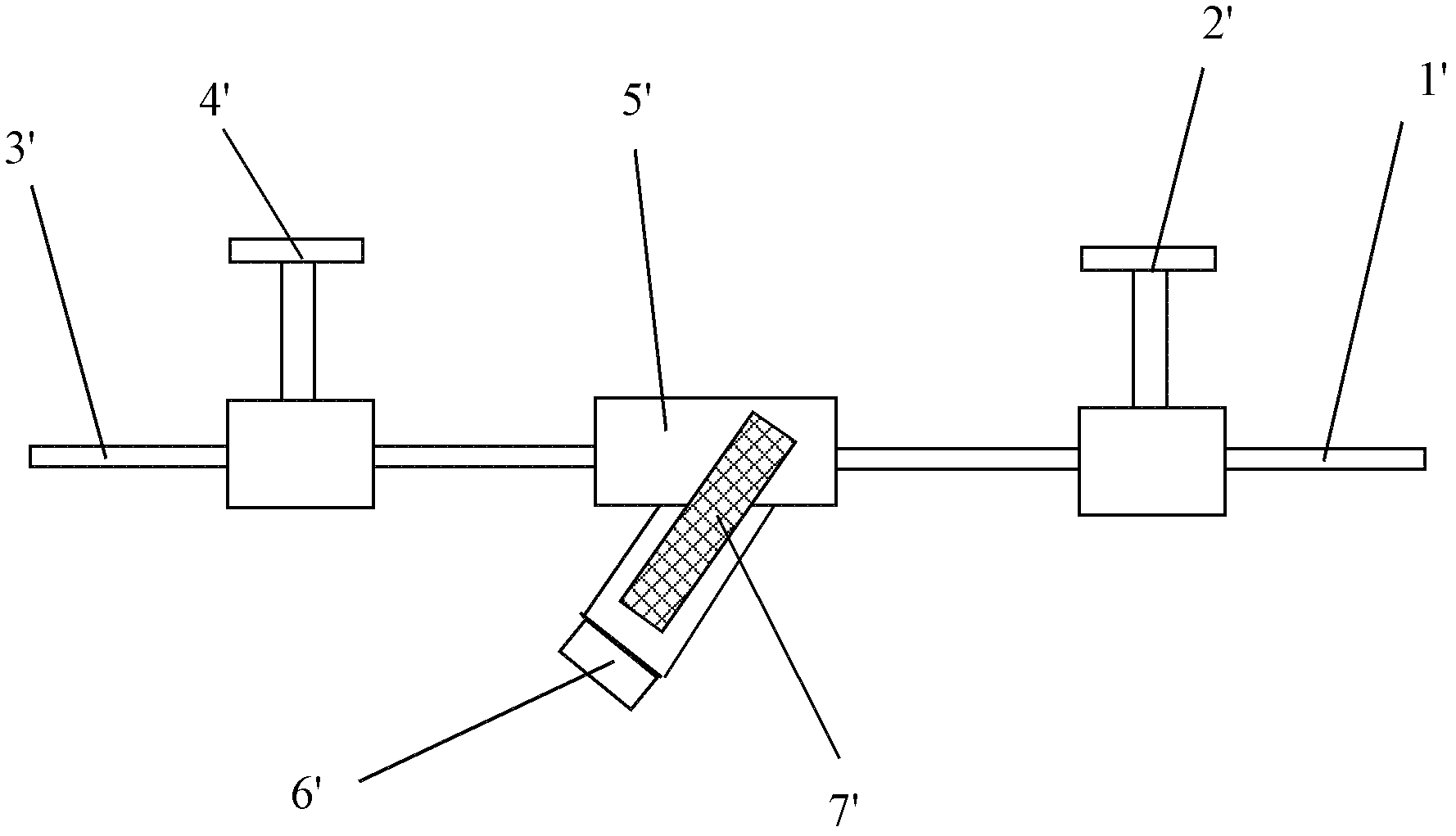

[0024] see figure 1 As shown, a Y-shaped water filter device in the prior art includes a water inlet pipe 1' at one end, a water inlet valve 2' for controlling the water inlet pipe 1', an outlet pipe 3' at the other end, a control The water outlet valve 4' of the water outlet pipe 3', the filter body 5', the cover plate 6' at the bottom of the filter body 5' and the filter element 7' inside the filter body 5'. Generally, the Y-shaped water filter device will be blocked after use. The usual method is to close the outlet valve 4' and the water inlet valve 2' of the Y-shaped water filter device, and close the cover plate 6' at the bottom of the Y-shaped water filter device. Open it, then remove the inner filter element 7' and wash it, then put the filter element 7' back into the filter body 5' after washing, and cover the cover plate 6', after completion, open the water inlet valve 2' and the water outlet valve 4'. However, this method of flushing the filter element is cumberso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com