Packaging assembly of air-conditioner compressor

A technology for air-conditioning compressors and packaging components, which is applied in the direction of special packaging objects, packaging, and packaged food. Guarantee the effect of repeated use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

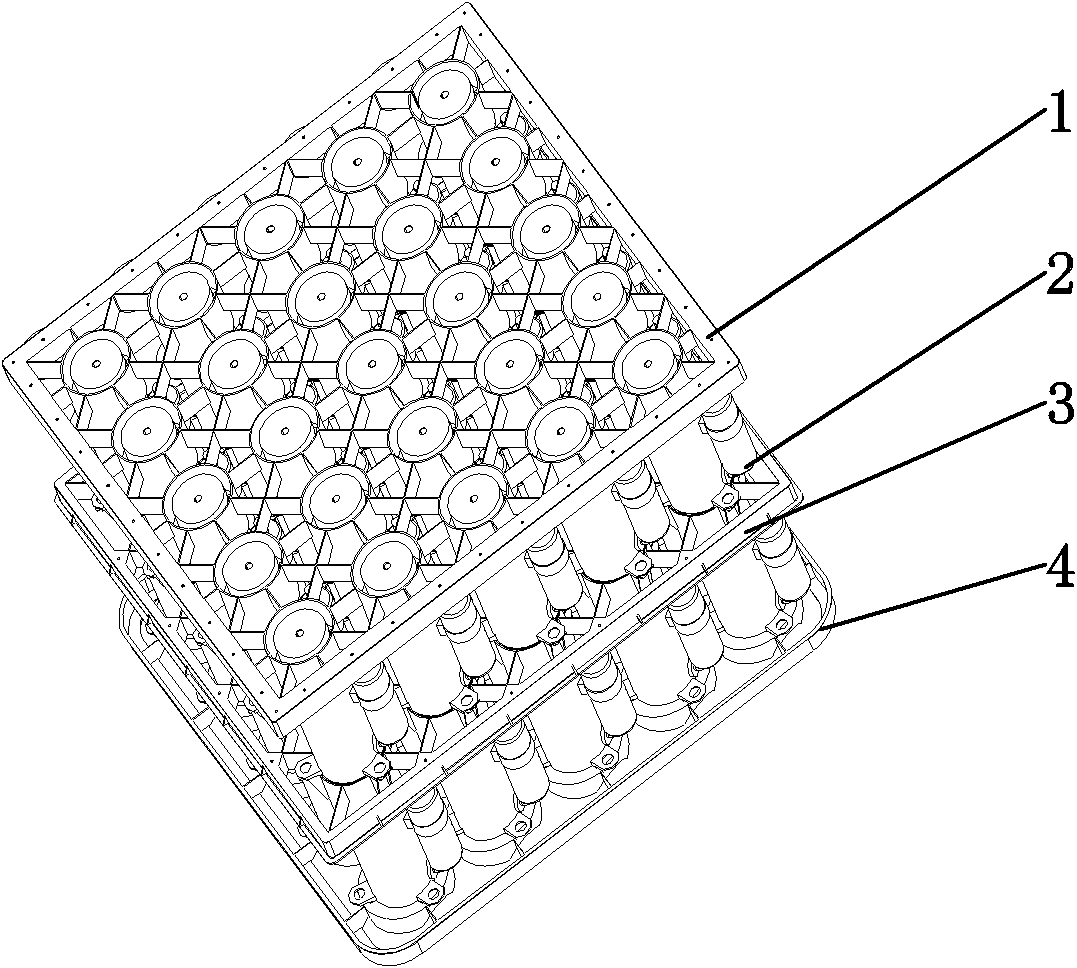

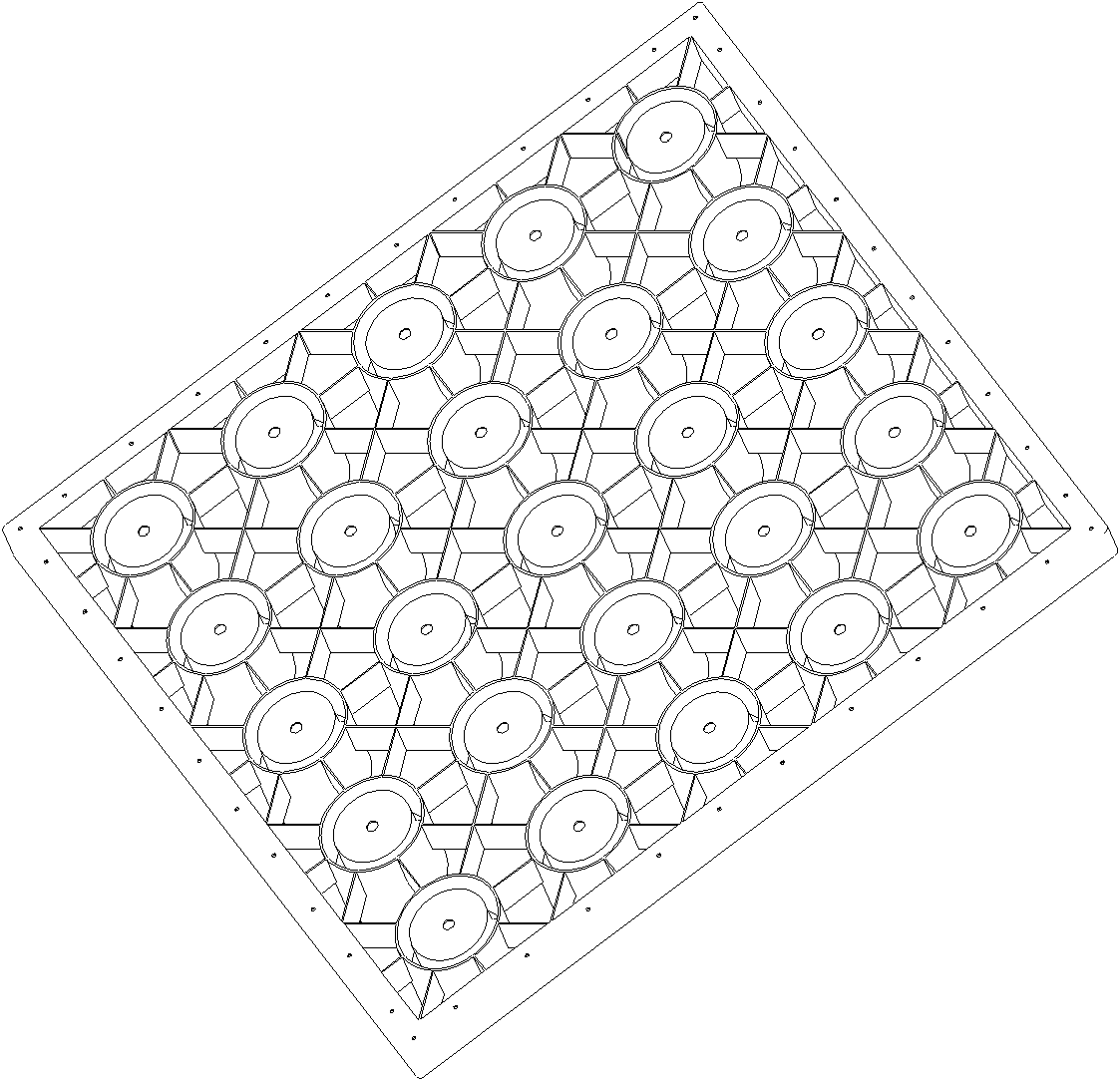

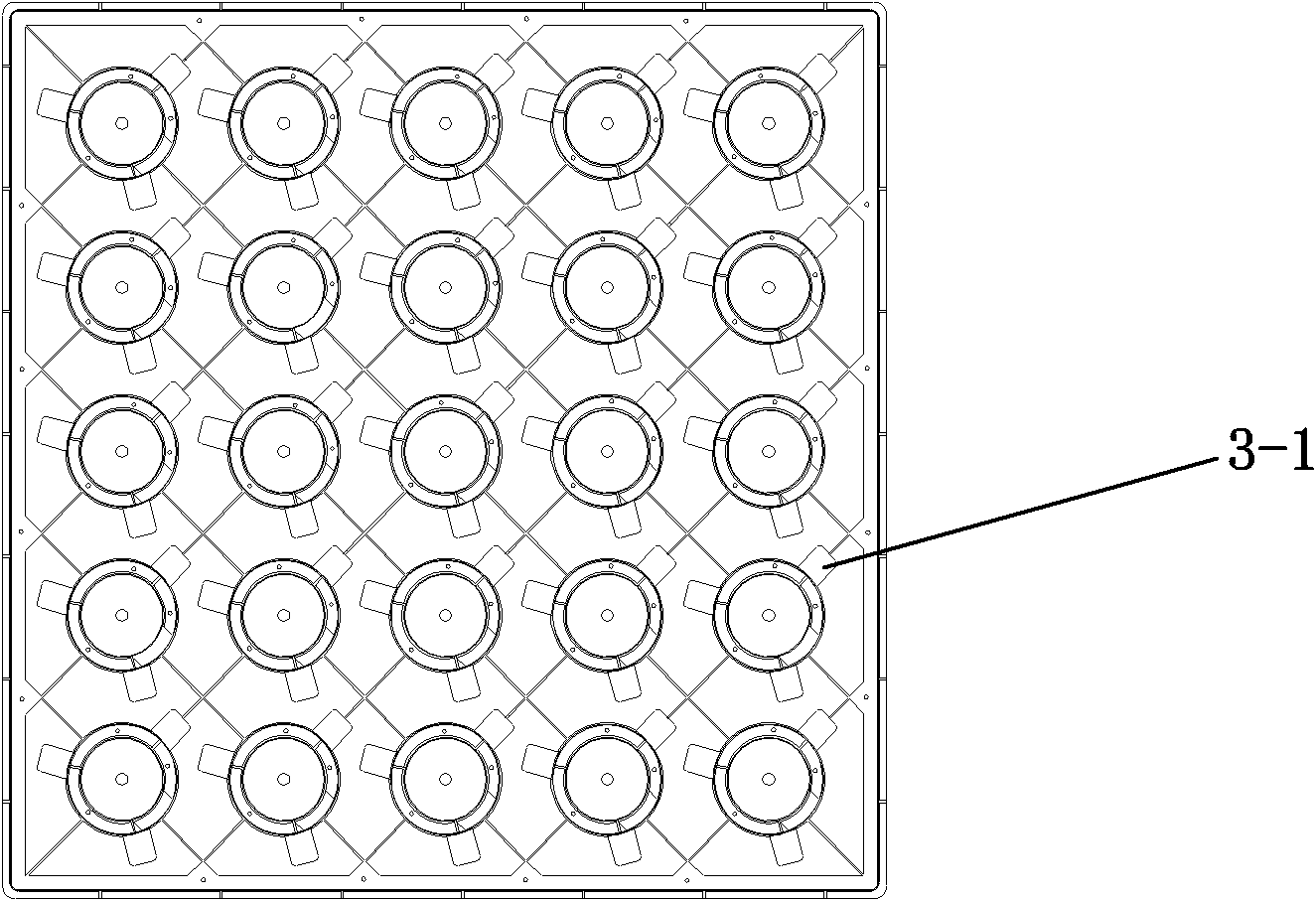

[0022] Such as Figure 1-5 As shown, an air conditioner compressor packaging assembly is composed of three structures: an upper fixing plate 1 , a middle fixing plate 3 , and a lower fixing plate 4 . The three fixing plates are made of continuous fiber reinforced polypropylene engineering plastic. Inside the middle fixing plate 3 and the lower fixing plate 4, there are a total of 25 buffer structures arranged in a 5×5 arrangement. A total of 25 fixing holes arranged in 5×5 are arranged inside the upper fixing plate 1 .

[0023] The buffer structure a of the middle fixing plate 3 includes a spherical groove arranged on the lower surface, a hole is arranged in the middle of the spherical groove, and a supporting boss group 3-1 is arranged on the upper surface, and each supporting boss group 3-1 consists of three Consists of a protruding support boss.

[0024] The buffer structure b of the lower fixing plate 4 includes a support boss group 4-1 composed of three protruding supp...

Embodiment 2

[0027] A packaging structure for an air conditioner compressor, the packaging structure is composed of an upper fixing plate and a middle fixing plate, three fixing holes are provided on the upper fixing plate, three buffer structures are provided on the middle fixing plate, and the rest are the same as in Embodiment 1 .

Embodiment 3

[0029] A packaging structure for an air conditioner compressor, the packaging structure is composed of an upper fixing plate and a lower fixing plate, 50 fixing holes are provided on the upper fixing plate, 50 buffer structures are provided on the lower fixing plate, and the rest are the same as in Embodiment 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com