Active type falling protector

An anti-fall device and anti-fall technology, which is applied in elevators, transportation and packaging, etc., can solve the problem that the anti-fall device does not have the function of overload and anti-fall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

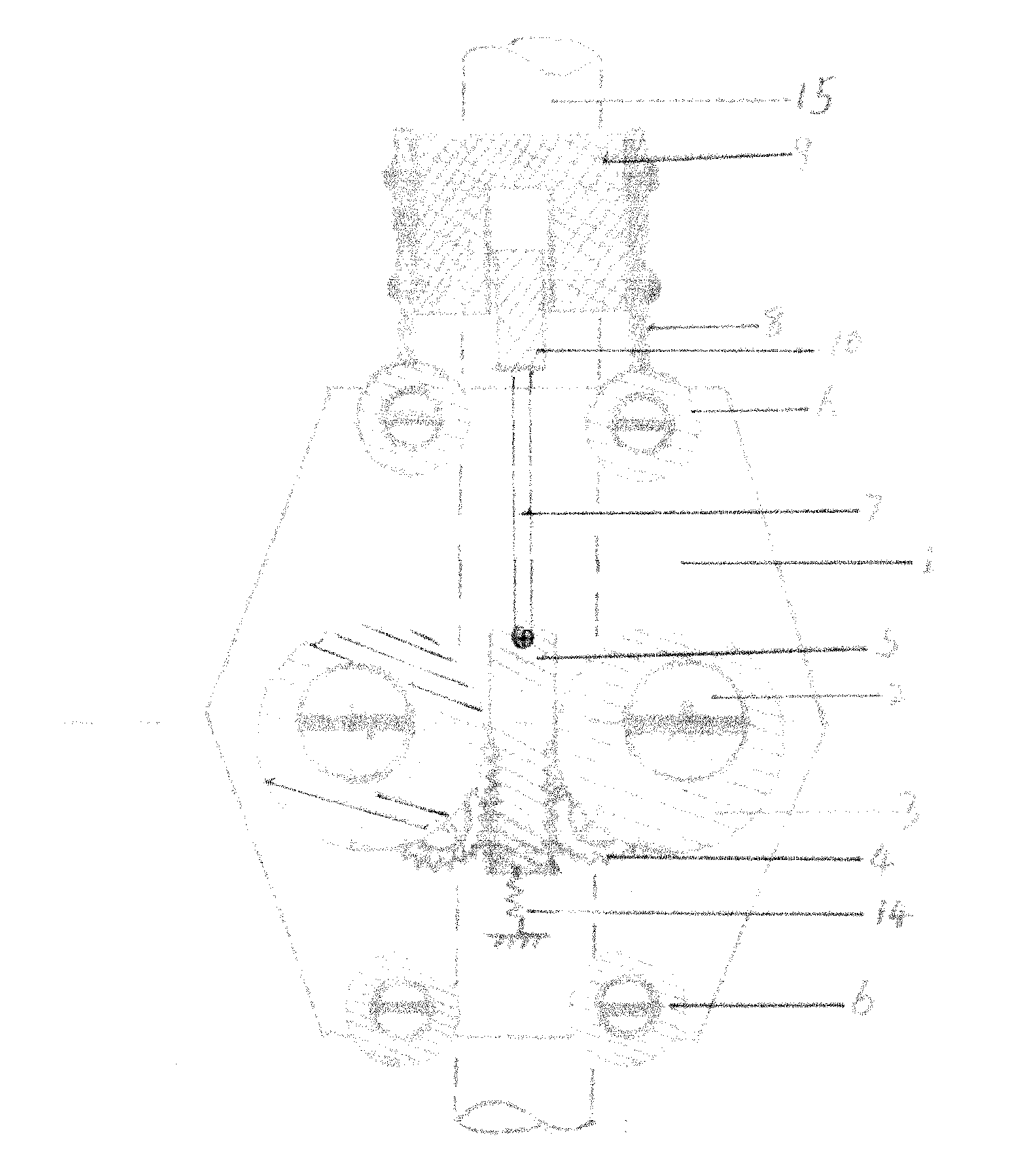

[0011] The active fall arrester of the present invention will be further described below in conjunction with the accompanying drawings.

[0012] refer to figure 1 Schematic diagram of the structure: in the figure, the coil 9 of the electromagnet is connected in parallel with the power supply of the lifting motor. Drive the eccentric card wheel 3 to block the guide rail 15. The state at this time is that the anti-falling device is a Kalaw guide rail when the lifting motor is not powered on. Only when the lifting motor is powered on and started, the electromagnet 9 can move and pull Armature 10, armature 10 drives pull rod 7, pull rod 7 pulls rack 5, rack 5 drives two pinions 4, two pinions 4 drive two eccentric card wheels 3, and two eccentric card wheels 3 rotate in opposite directions, So the card wheel is in an open state, and the elevator or elevator can move freely up and down. When the elevator or elevator is overloaded, the people in the elevator or elevator can cut off...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com