Preparation method of high-solid-content butadiene-styrene latex

A technology of styrene-butadiene latex and high solid content, which is applied in the field of preparation of high-solid content styrene-butadiene latex, can solve problems such as high viscosity and narrow particle size distribution, and achieve easy control of agglomerated particle size, high production efficiency, and satisfying The effects of production, processing and performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

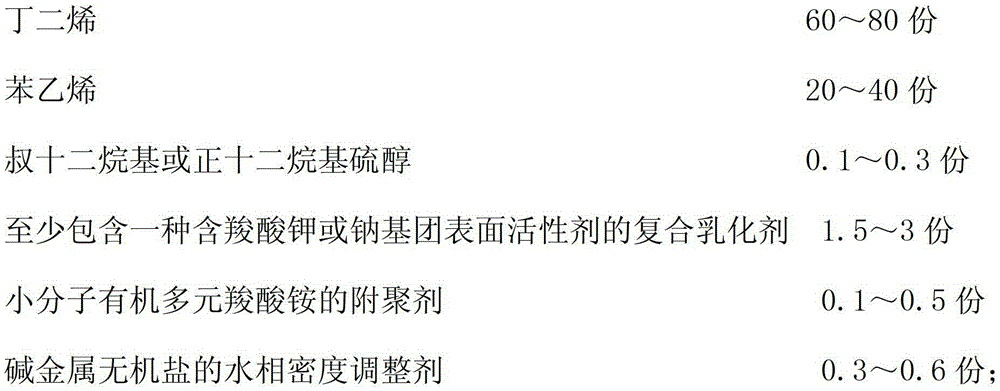

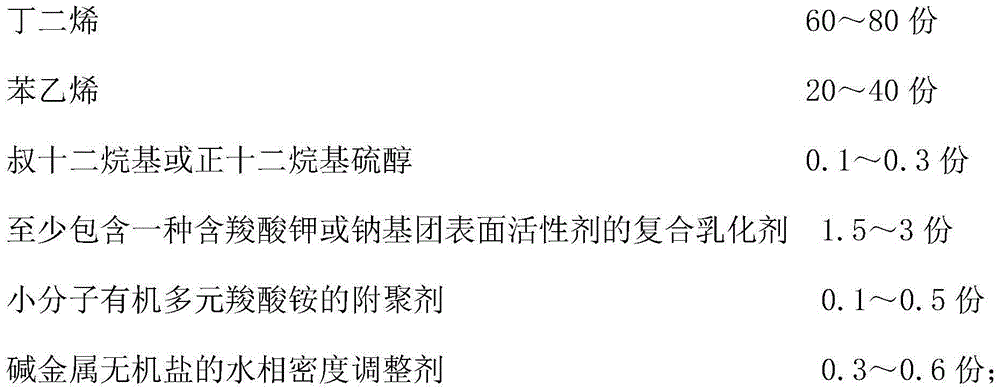

Method used

Image

Examples

Embodiment 1

[0031] a. Raw materials: 75 parts of butadiene, 25 parts of styrene, 0.2 parts of n-dodecyl mercaptan, 0.8 parts of potassium oleate, 0.5 parts of sodium dodecyl diphenyl ether disulfonate, polyoctearyl alcohol 1.2 parts of oxyethylene ether (20), 0.15 parts of ammonium oxalate, 0.5 parts of sodium hexametaphosphate, 0.25 parts of ammonium persulfate, 0.1 parts of sodium sulfite, 103 parts of deionized water (conductivity ≤ 5 μS / cm);

[0032] b. Emulsion polymerization: Add 91 parts of deionized water, 0.6 parts of potassium oleate, 0.35 parts of sodium dodecyl diphenyl ether disulfonate, and 0.9 parts of stearyl polyoxyethylene ether (20) to the polymerization kettle in a vacuum state. 1 part, 0.4 part of sodium hexametaphosphate, stir and dissolve, add 13 parts of styrene, 0.1 part of n-dodecyl mercaptan, vacuumize to -0.05MPa, fill nitrogen to 0.3MPa, repeat 3 times, exhaust nitrogen to the kettle Medium to slightly positive pressure, add 38 parts of butadiene to the reacti...

Embodiment 2

[0041] a. Raw materials: 60 parts of butadiene, 40 parts of styrene, 0.2 parts of n-dodecyl mercaptan, 1.2 parts of disproportionated potassium abietate, 0.3 parts of sodium dodecylbenzenesulfonate, nonylphenol polyoxyethylene 1.2 parts of ether (15), 0.12 parts of ammonium oxalate, 0.5 parts of sodium hexametaphosphate, 0.25 parts of ammonium persulfate, 0.1 parts of sodium sulfite, 103 parts of deionized water (conductivity ≤ 5 μS / cm);

[0042] b. Emulsion polymerization: Add 91 parts of deionized water, 0.9 parts of disproportionated potassium abietate, 0.23 parts of sodium dodecylbenzenesulfonate, and 0.9 parts of nonylphenol polyoxyethylene ether (15) into the polymerization kettle under vacuum , 0.4 parts of sodium hexametaphosphate, after stirring and dissolving, add 20 parts of styrene and 0.1 part of n-dodecyl mercaptan, vacuumize to -0.05MPa, fill with nitrogen to 0.3MPa, repeat 3 times, and discharge nitrogen into the kettle Slightly positive pressure, add 30 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com