Automatic deicing device of barrel head of chimney and deicing method thereof

A chimney and ice-melting technology, which is applied in the direction of combustion method, waste gas exhaust device, combustion product treatment, etc., can solve the problem of icing at the head of the chimney, and achieve the effect of solving the problem of icing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

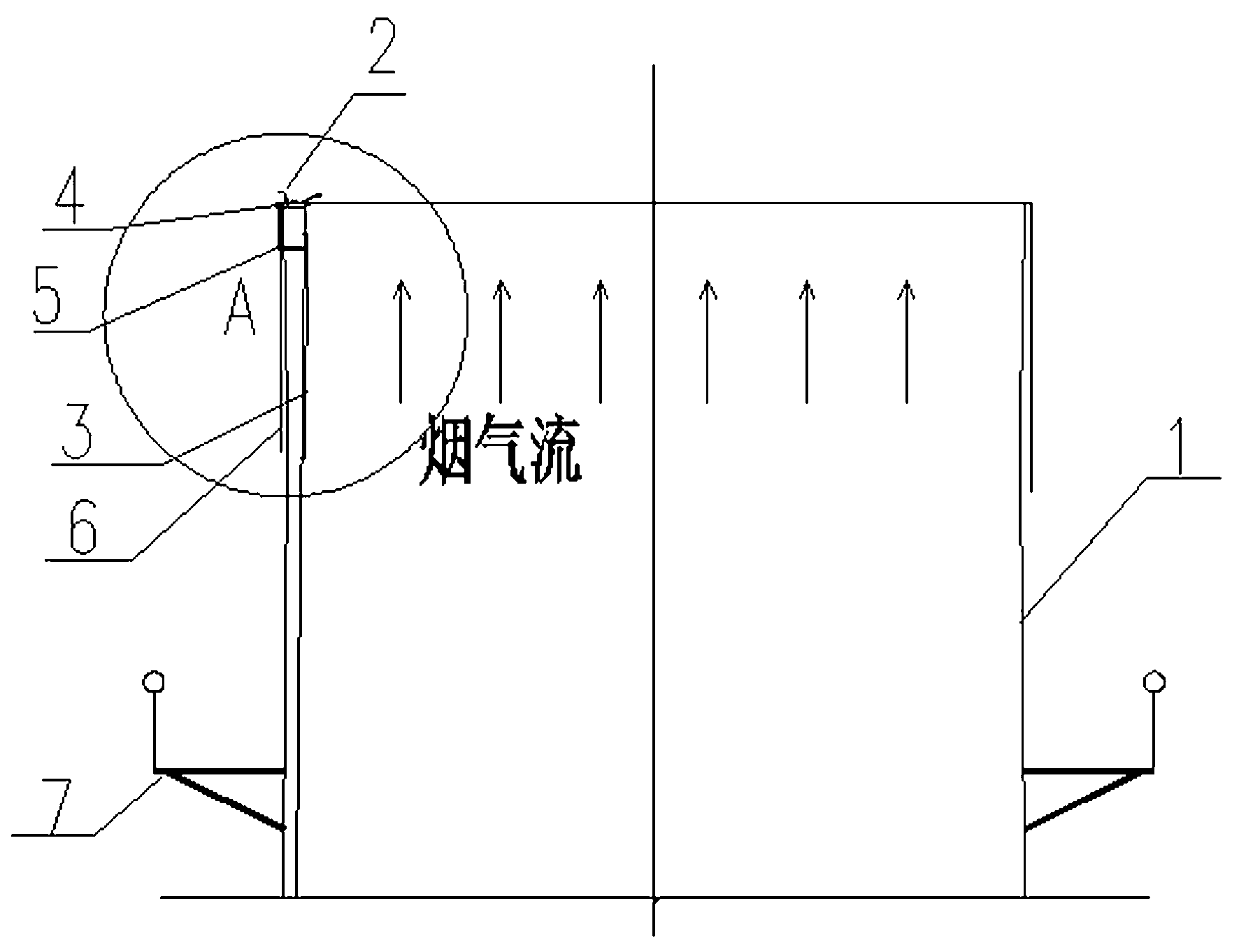

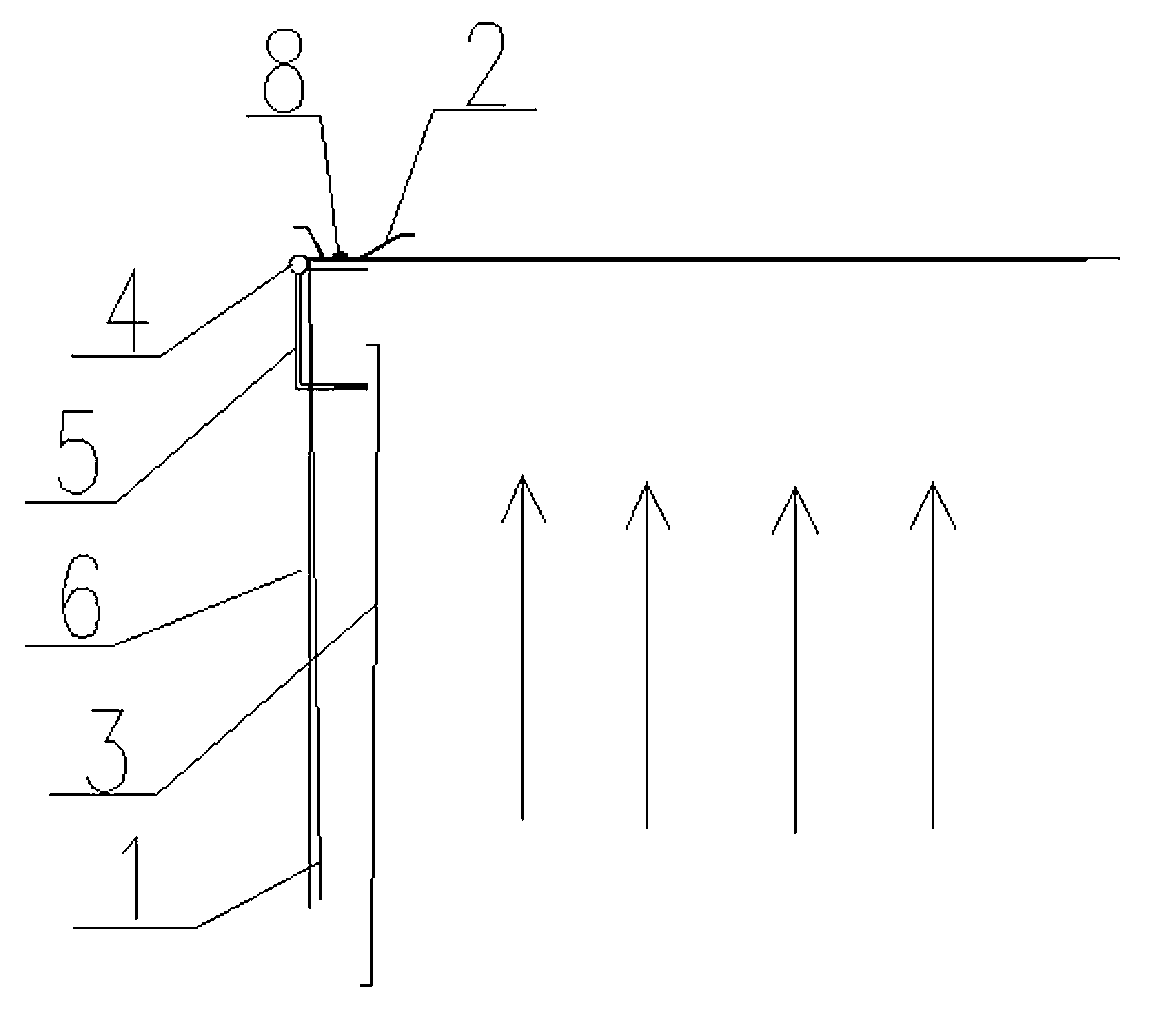

[0011] Below in conjunction with accompanying drawing, the present invention is further described:

[0012] Such as figure 1 , figure 2 As shown, a chimney head automatic ice device and ice melting method thereof, a steel needle 2 is arranged on the top of the chimney 1 head, the steel needle 2 is fixed on the top of the chimney 1 by bolts 8, and the inner circumference of the inner pipe top of the chimney 1 is arranged There is a heating main pipe 3, and an ice-melting pipe 4 is arranged on the outside of the top of the chimney 1. The heating main pipe 3 and the ice-melting pipe 4 are connected by a connecting pipe 5. The outer surface of the cylinder head 1 is provided with a polymer of fluorosilane and methacrylic acid to form a hydrophobic Layer 6. In the present invention, a steel needle 2 is arranged on the top of the chimney 1. Due to the high-altitude environment, the random wind speed will not be small. An appropriate steel needle is installed on the top of the chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com