gas stove

A technology for gas stoves and stoves, which is applied in the directions of burners, combustion methods, heating fuels, etc., can solve the problems of supplying primary air, difficult necks, and easy accumulation of heat in stove burners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

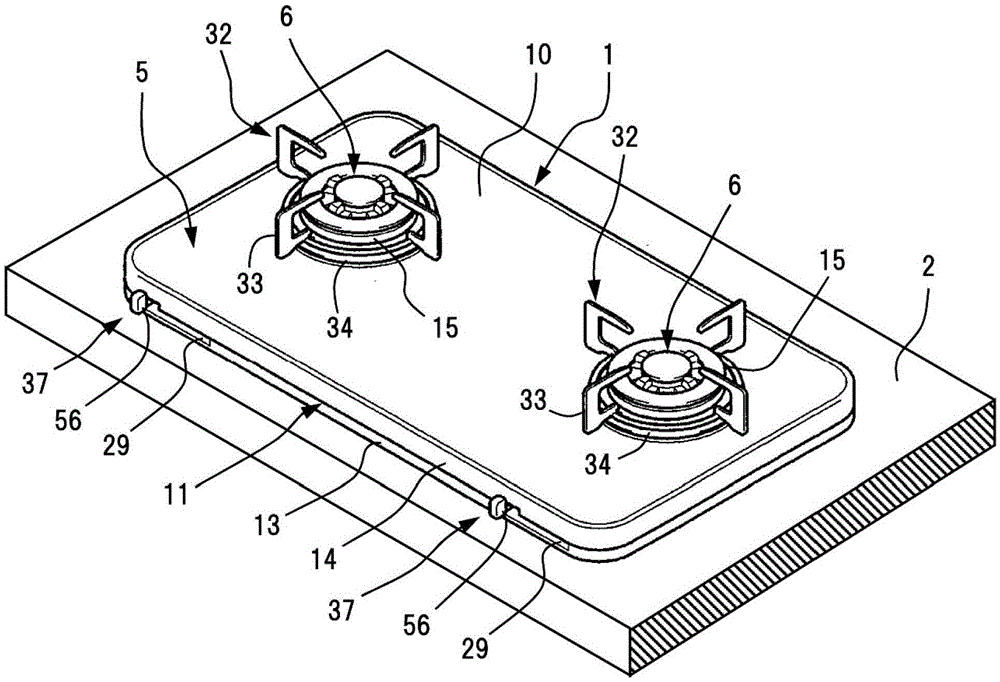

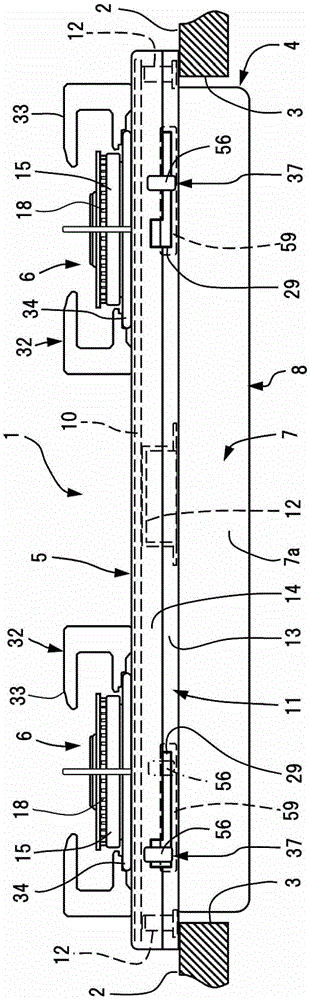

[0023] An embodiment of the present invention will be described with reference to the drawings. Such as figure 1 As shown, the gas stove 1 of the present embodiment is a built-in stove, so as to fall into the opening 3 for the stove (refer to figure 2 ) way to set. Wherein, the opening 3 for a stove is formed on a countertop 2 of a kitchen unit.

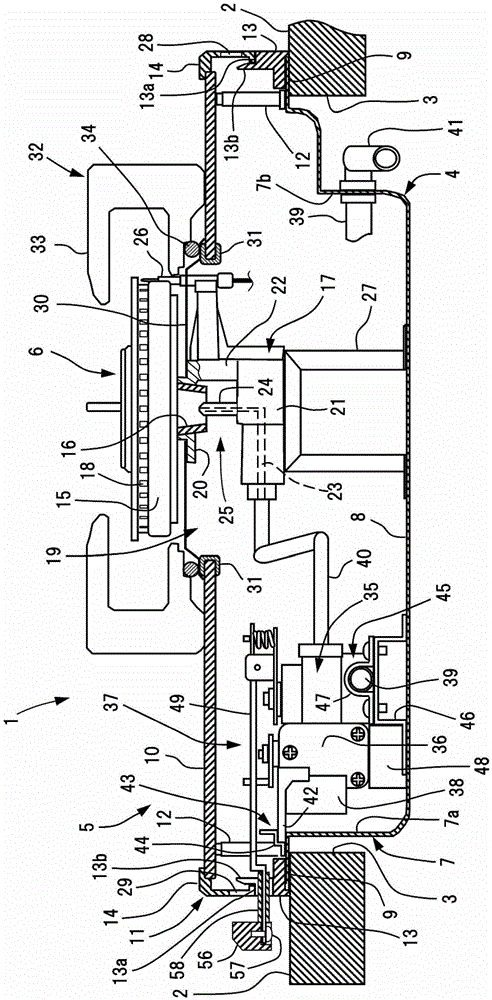

[0024] Such as figure 2 As shown, the gas stove 1 includes a stove main body 4 , a panel portion 5 , and a stove burner 6 . Such as image 3 As shown, the main body 4 of the furnace is composed of a substantially square cylindrical peripheral wall 7 and a bottom wall 8 closing the bottom of the peripheral wall 7 . A flange portion 9 protruding horizontally outward is formed on the upper end of the peripheral wall 7 of the furnace main body 4 . The flange portion 9 is hung and fixed on the upper surface of the periphery of the opening 3 for a stove. Thereby, the stove main body 4 is in the installation state suspended inside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com