Connection structure and anisotropic conductive adhesive

A connection structure, anisotropic technology, applied in the direction of conductive adhesives, connections, adhesives, etc., can solve problems such as difficult to repair and damaged appearance, and achieve the effect of preventing appearance damage and reducing light leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] 60 parts by mass of polyester polyurethane resin (trade name: UR8200, produced by Toyobo Co., Ltd., dissolved in a mixed solvent of methyl ethyl ketone / toluene=50 / 50 to obtain 20 mass % of the result) as a film-forming resin, 34 parts by mass of free Base polymeric resin (trade name: EB-600, manufactured by Daicel Cytec Co., Ltd. (Daycel Cytec Co., Ltd.)), 1 part by mass of silane coupling agent (trade name: KBM-503, manufactured by Shin-Etsu Chemical Co., Ltd.), 1 mass part of phosphoric acid acrylate (trade name: P-1M, manufactured by Kyoei Chemical Co., Ltd.) and 4 mass parts of reaction initiator (trade name: Perhexa C (パーヘキサ C), manufactured by NOF Corporation) were blended In the adhesive, disperse conductive particles (trade name: AUL705, manufactured by Sekisui Chemical Co., Ltd.) so that the particle density is 5000 particles / mm 2 , and further dispersed 12 parts by mass of a titanium-based black pigment with an average primary particle diameter of 60 nm (trade...

Embodiment 2

[0070] The average primary particle diameter of 12 parts by mass is dispersed as a titanium-based black pigment (trade name: 13M-C, manufactured by Mitsubishi Materials) of 100 nm, and an anisotropic conductive film is prepared in the same manner as in Example 1 except that .

[0071] The transmittance of the anisotropic conductive film of Example 2 was 13.3%. In addition, the initial on-resistance of the bonded structure prepared using the anisotropic conductive film was 2.0Ω, and the on-resistance after the high-temperature and high-humidity test was 5.5Ω. In addition, the initial peel strength was 6.1 N / cm, and the peel strength after the high temperature and high humidity test was 4.0 N / cm. In addition, the evaluation of the light-shielding property was ⊚. Therefore, the overall decision is B. These results are shown in Table 1.

Embodiment 3

[0073] An anisotropic conductive film was prepared in the same manner as in Example 1 except that 12 parts by mass of a titanium-based black pigment (trade name: Tilack D, manufactured by Ako Kasei Co., Ltd.) having an average primary particle diameter of 800 nm was dispersed.

[0074] The transmittance of the anisotropic conductive film of Example 3 was 13.8%. In addition, the initial on-resistance of the bonded structure prepared using the anisotropic conductive film was 1.8Ω, and the on-resistance after the high-temperature and high-humidity test was 3.2Ω. In addition, the initial peel strength was 6.0 N / cm, and the peel strength after the high temperature and high humidity test was 4.3 N / cm.

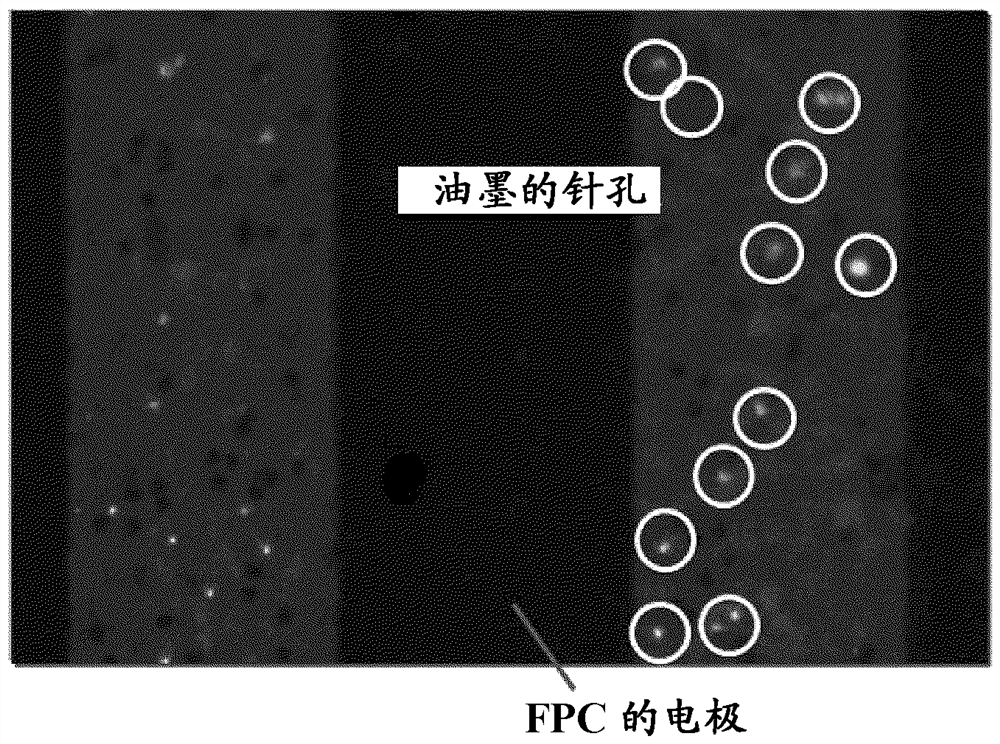

[0075] in addition, image 3 It is a photograph of the bonded structure produced using the anisotropic conductive film of Example 3, irradiated with light from the glass substrate for evaluation side in which pinholes were formed in advance, and observed with a metal microscope from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com