Vacuum liquid refrigeration sampling device

A sampling device and liquid technology, applied in the field of direct research on the liquid surface in vacuum chambers, can solve the problems of damage to the sealing effect of the O-ring of the sealing part, complicated processing technology, inconvenient disassembly and cleaning, etc., to achieve convenient disassembly and good cooling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

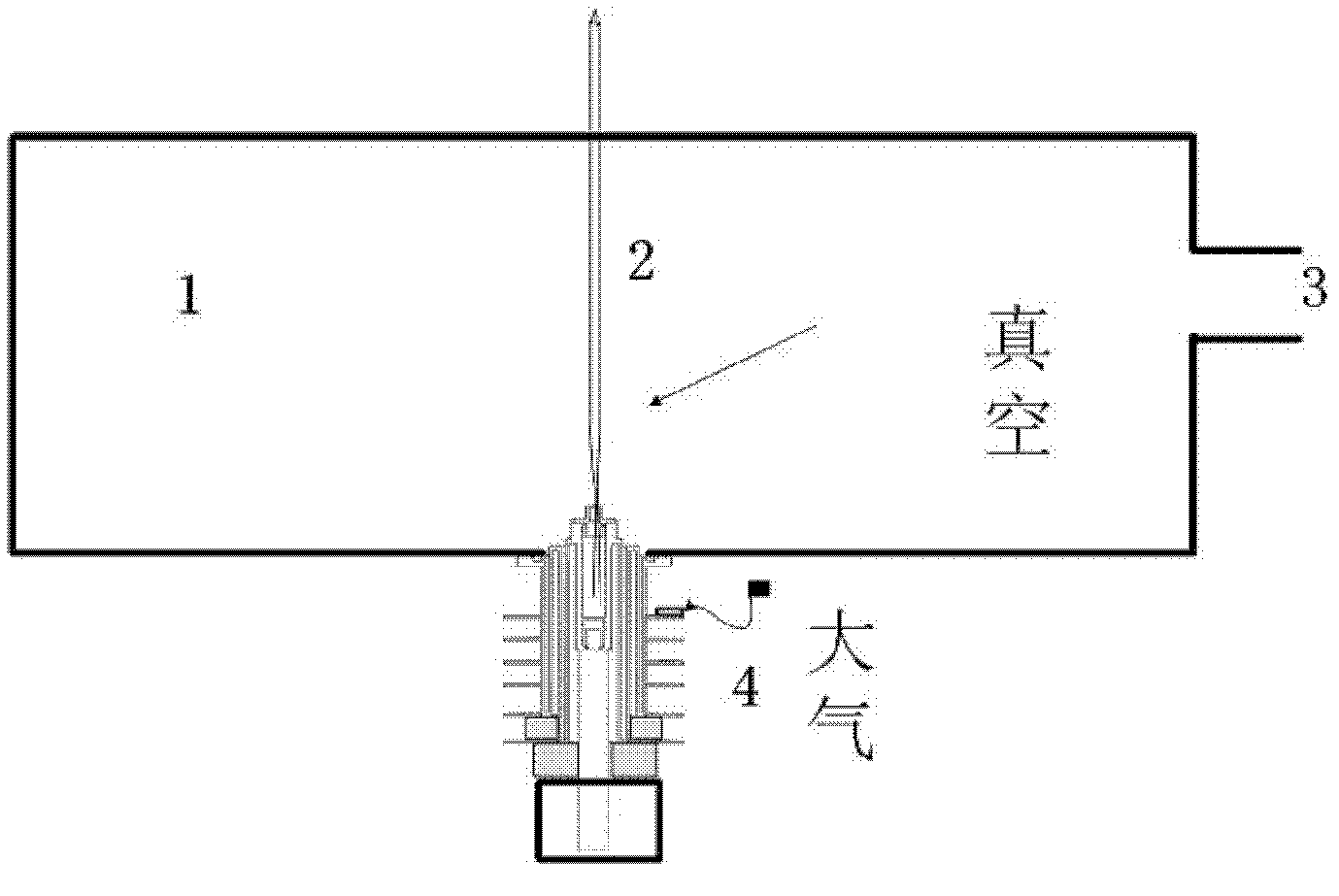

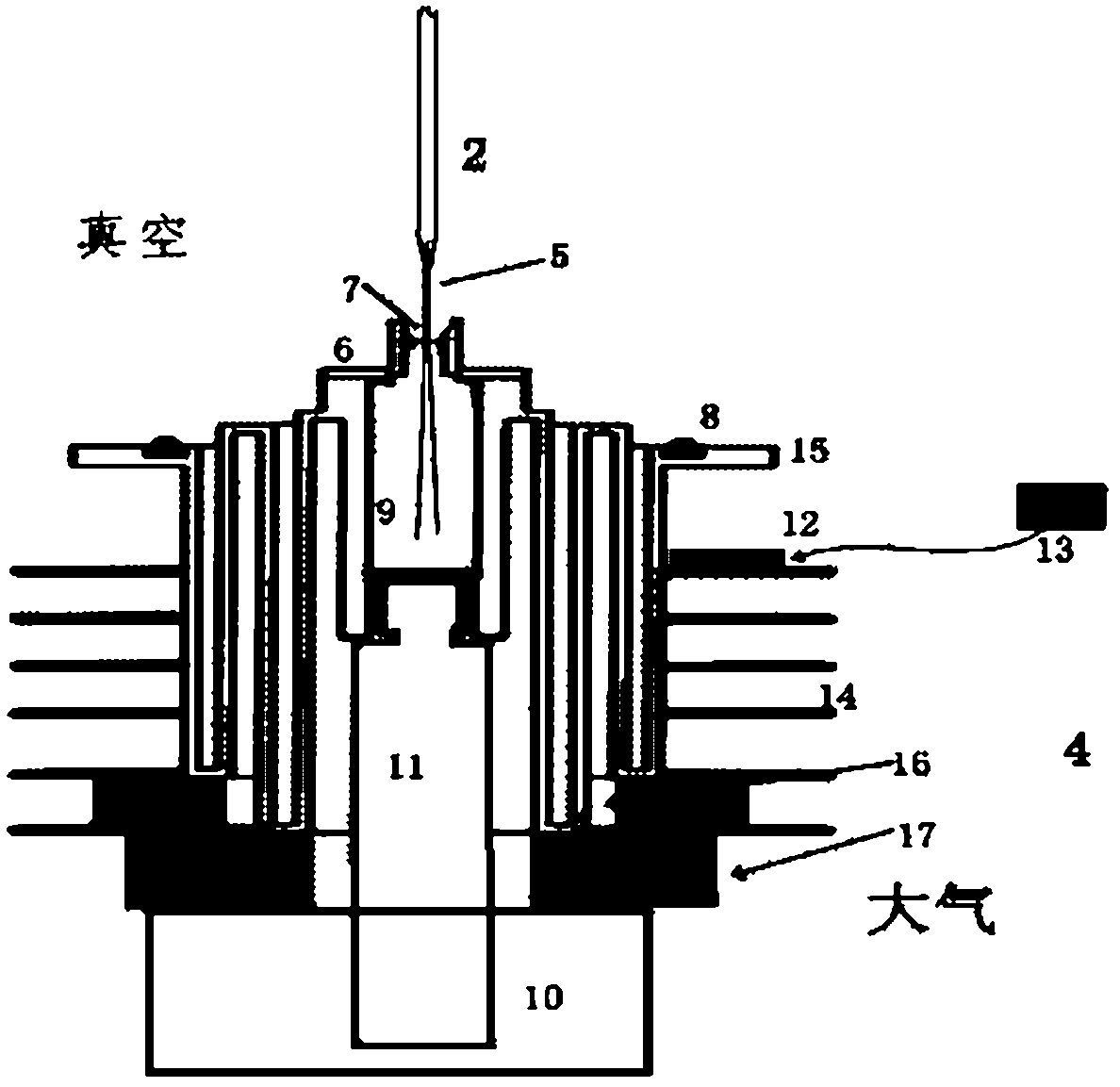

[0024] The invention is used for direct vacuum sampling of liquid samples, and the liquid samples are sprayed into the vacuum chamber 1 through the capillary 2 . Part of the liquid sprayed into the vacuum chamber 1 volatilizes into gas, and is discharged to the vacuum chamber through the molecular pump of the exhaust system 3, and most of the liquid enters the cold trap through the inverted tapered small hole 7 at the upper end of the cold trap 4. The area between the outlet of the capillary 2 and the upper end of the cold trap 4 is the liquid analysis area 5 .

[0025] Such as figure 1 As shown, one end of the metal freezing shaft 11 is directly inserted into the liquid nitrogen 10, and the other end is connected with the liquid freezing chamber 9 through threads. The low temperature of the liquid nitrogen is transmitted to the liquid freezing chamber 9 and the cold trap upper cover 6 through the freezing axis 11 . The cold trap upper cover 6 is connected with the liquid fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com