Low-temperature high-pressure rotary viscometer for well cementation cement slurry

A rotational viscometer and cementing slurry technology, which is applied in instruments, measuring devices, scientific instruments, etc., can solve the problems that the viscometer performance of cement has a great influence, restricts the research and development of low-temperature cement system, and the rapid change of viscosity performance, etc. , to avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical solutions and advantages of the present invention clearer, the exemplary embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings. Apparently, the described embodiments are only a part of the embodiments of the present invention, and are not exhaustive of all the embodiments. And in the case of no conflict, the embodiments and the features in the embodiments of the present invention can be combined with each other.

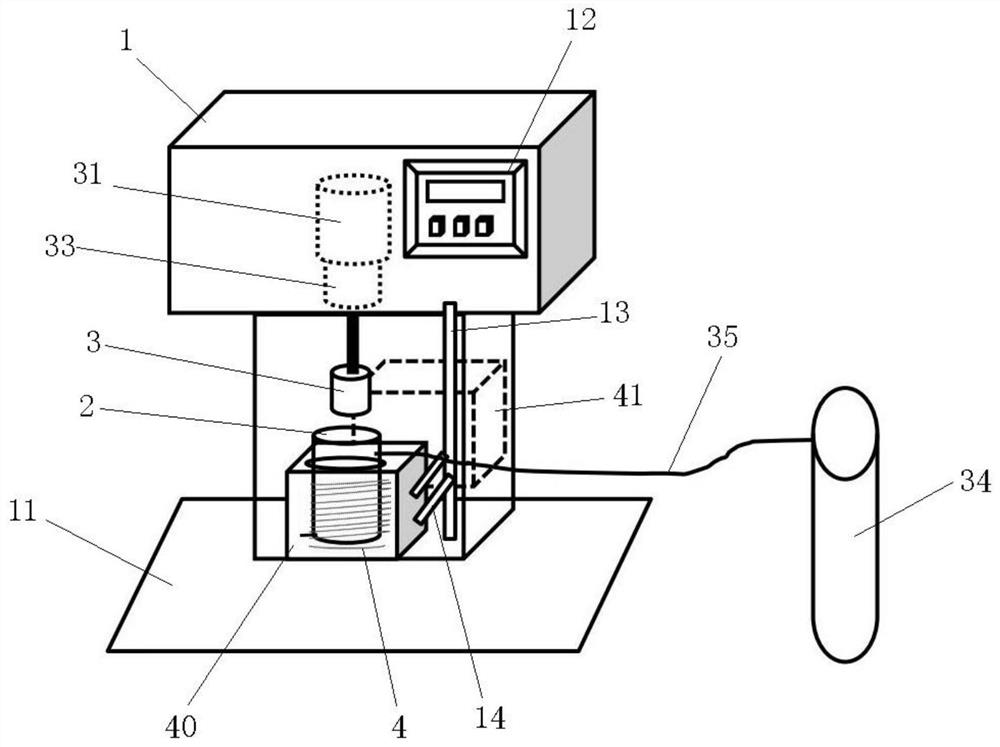

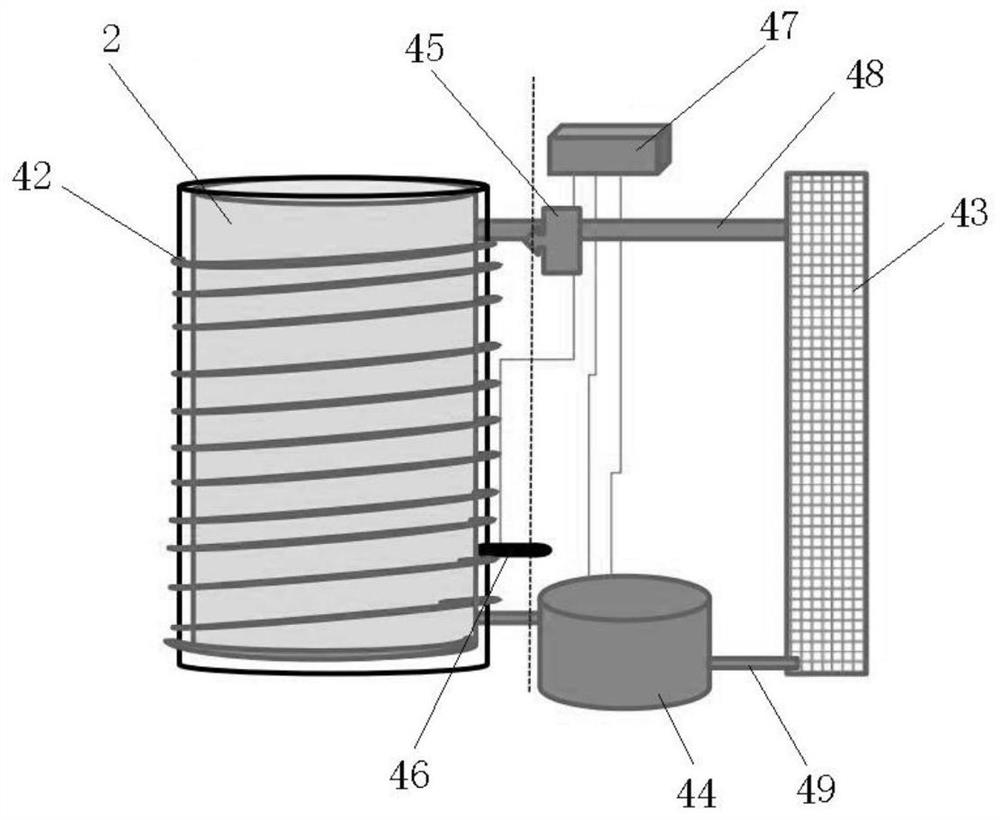

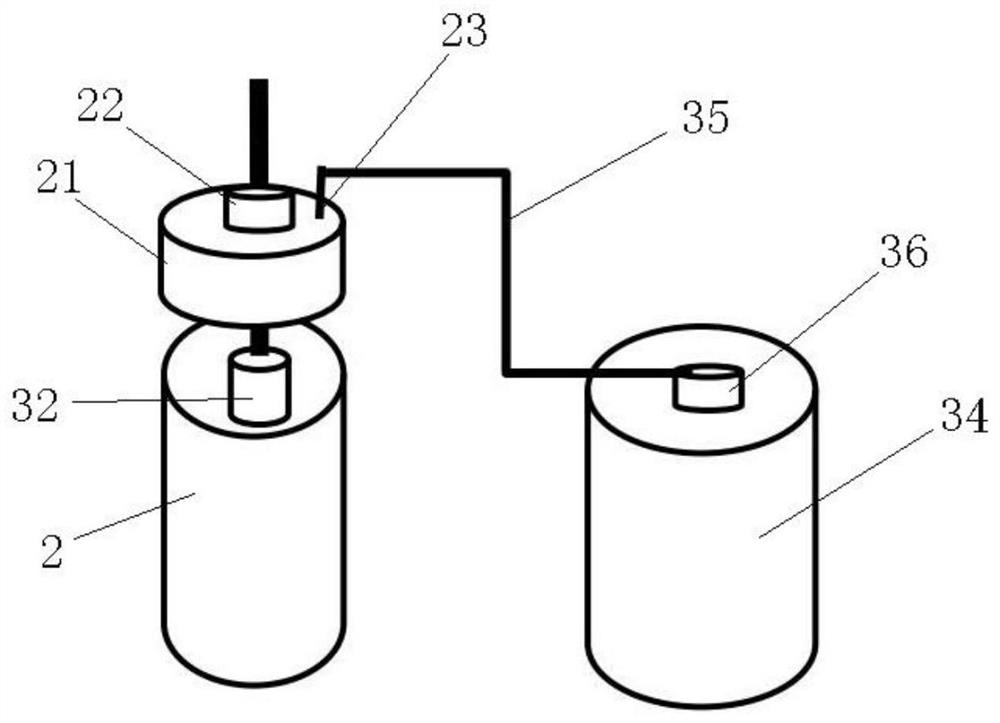

[0035] figure 1 Schematically shows a low-temperature, high-pressure rotational viscometer for cementing slurry according to an embodiment of the present invention, including a viscometer host 1, the viscometer host 1 is arranged on a base 11 and has a certain distance from the base 11 . The edge of the viscometer host 1 is connected to the base 11 through a bracket. A measuring cup 2 is arranged below the viscometer host 1 , and the measuring cup 2 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com