Front opening unified pod with latch structure

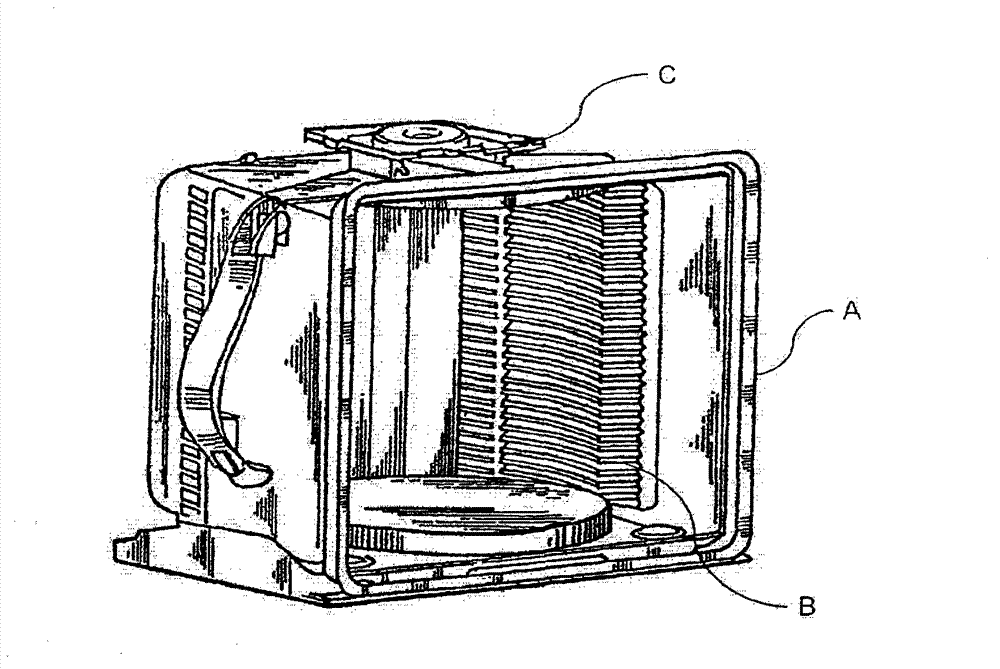

一种前开式晶圆盒、晶圆的技术,应用在连接构件、包装物品类型、特殊包装物件等方向,能够解决前开式晶圆盒冲击、顶面破损、大型晶圆片裂损等问题,达到避免震动及碰撞、防止尘埃的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

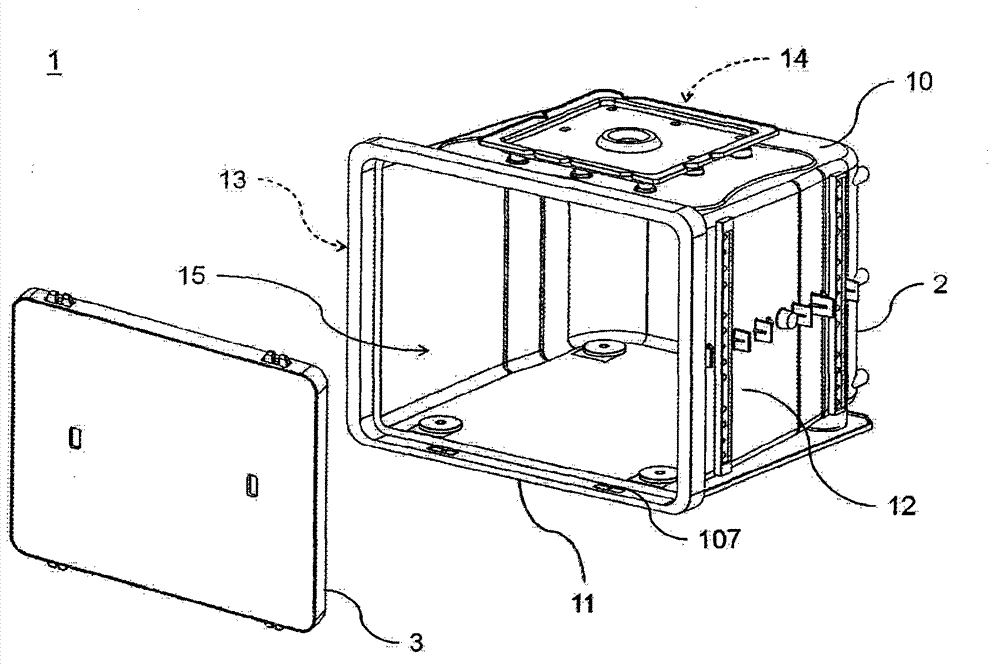

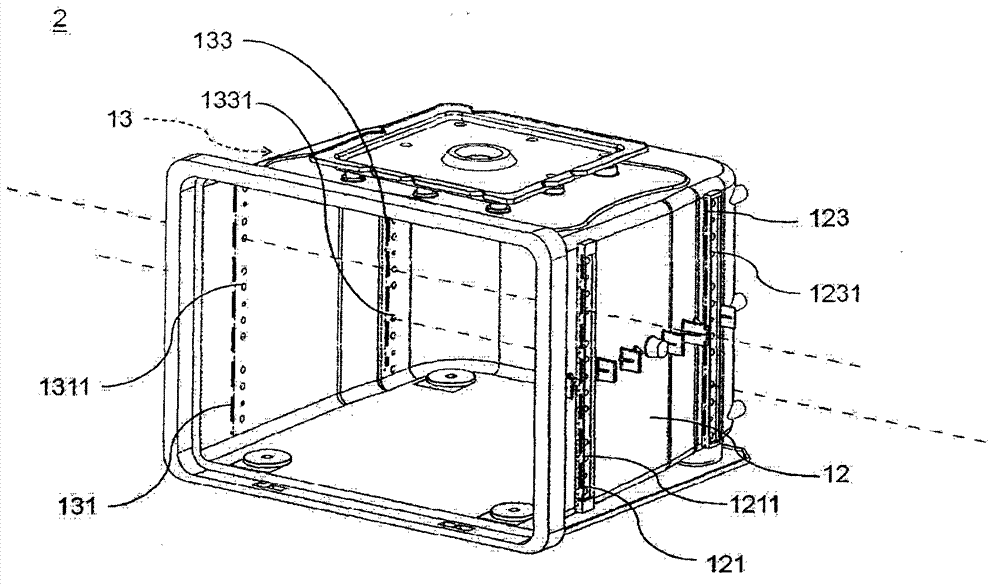

[0120] In order to have a further understanding and understanding of the structural features and the achieved effects of the present invention, preferred embodiments and detailed descriptions are used, which are described as follows:

[0121] Because the present invention discloses a wafer cassette, especially a wafer cassette with calibrated supports; some of the wafer cassette manufacturing, cassette material, and through hole correction methods used therein are based on existing Technology to achieve, so in the following description, not a complete description. In addition, the drawings in the following text are not completely drawn based on actual relevant dimensions, and their function is only to express schematic diagrams related to the features of the present invention.

[0122] First, see figure 2 , Is a schematic diagram of a box body of a front-opening wafer box according to an embodiment of the present invention. Such as figure 2 As shown, the front-opening wafer box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com