Welding rod special for nuclear power 20-control chrome steel

An electrode and chromium steel technology is applied in the field of special welding materials for nuclear power 20 chromium steel, which can solve the problems of low chromium content and can not meet the welding requirements of 20 chromium steel, and achieve the effect of improving the anti-FAC performance and ensuring the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

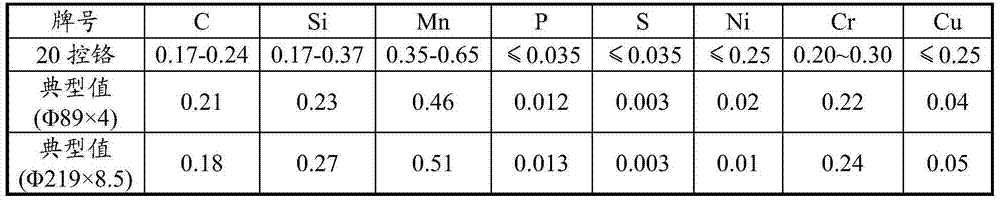

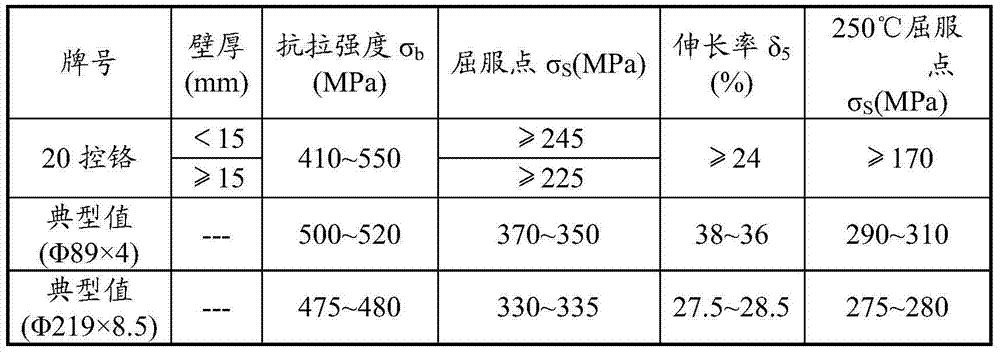

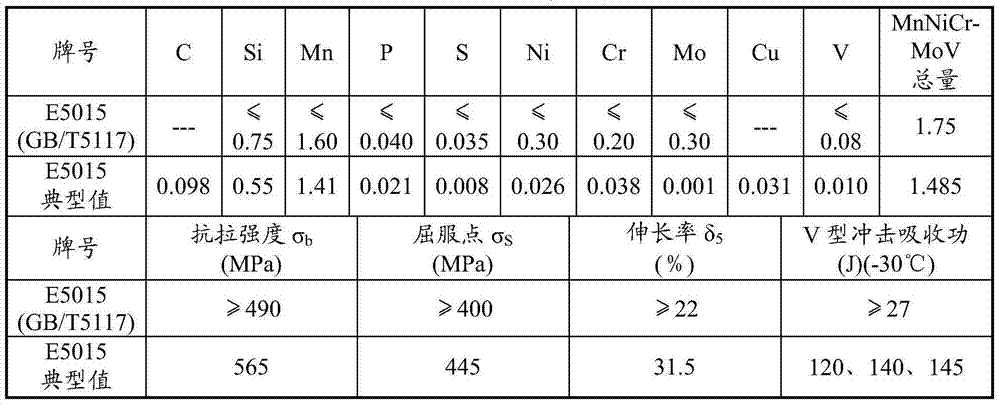

[0023] In order to cooperate with the 20-control chromium steel, the inventor has obtained the design values of the chemical composition, mechanical properties, core wire chemical composition and coating formula of the deposited metal of the special welding rod for nuclear power 20-control chromium steel of the present invention after many experiments, such as Table 4-7 shows.

[0024] Table 4. The design value of the chemical composition of the deposited metal of the special electrode for 20-control chromium steel / wt%

[0025]

[0026] Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com