Wire labelling mechanism and method

A labeling and wire technology, applied in the directions of labeling machines, labels, packaging, etc., can solve the problems of label sticking, complex structure, poor bonding effect, etc., to reduce the footprint of the mechanism, the feeding method is simple, and the structure of the mechanism is simplified. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments. It should be noted that the following is only a detailed description of the preferred embodiments of the present invention, and does not constitute any limitation to the present invention.

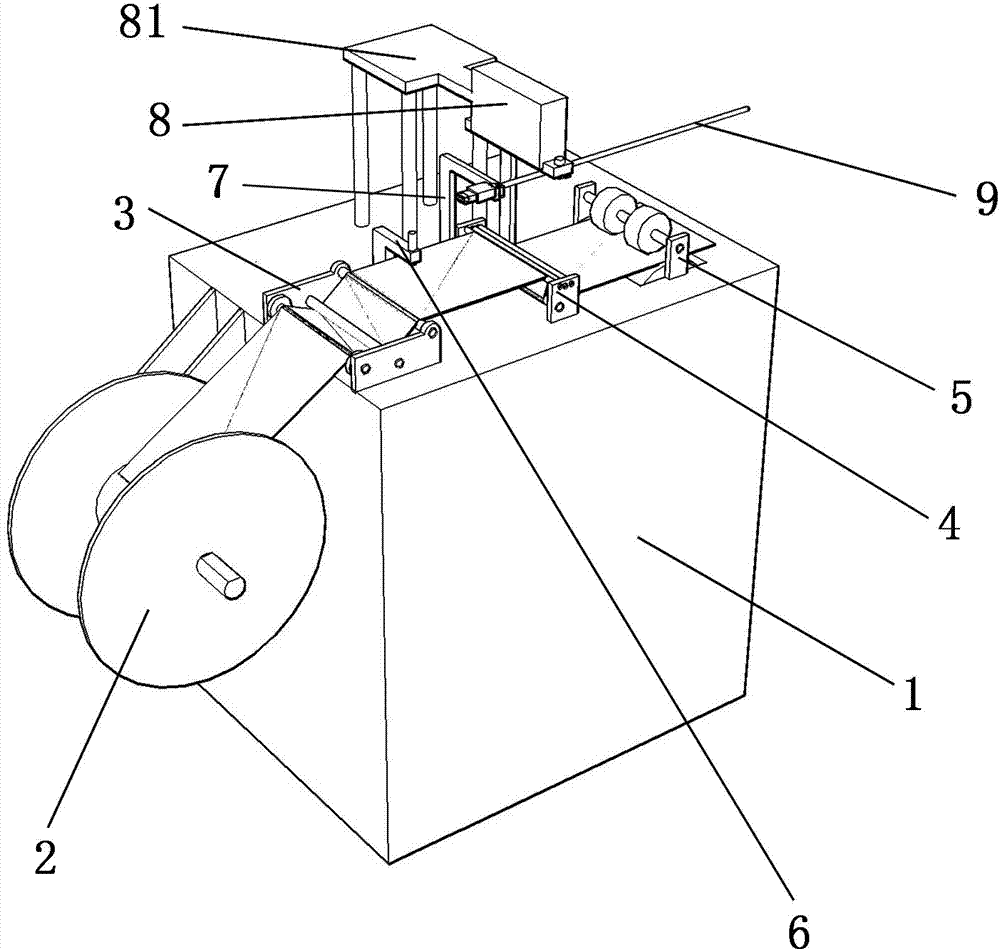

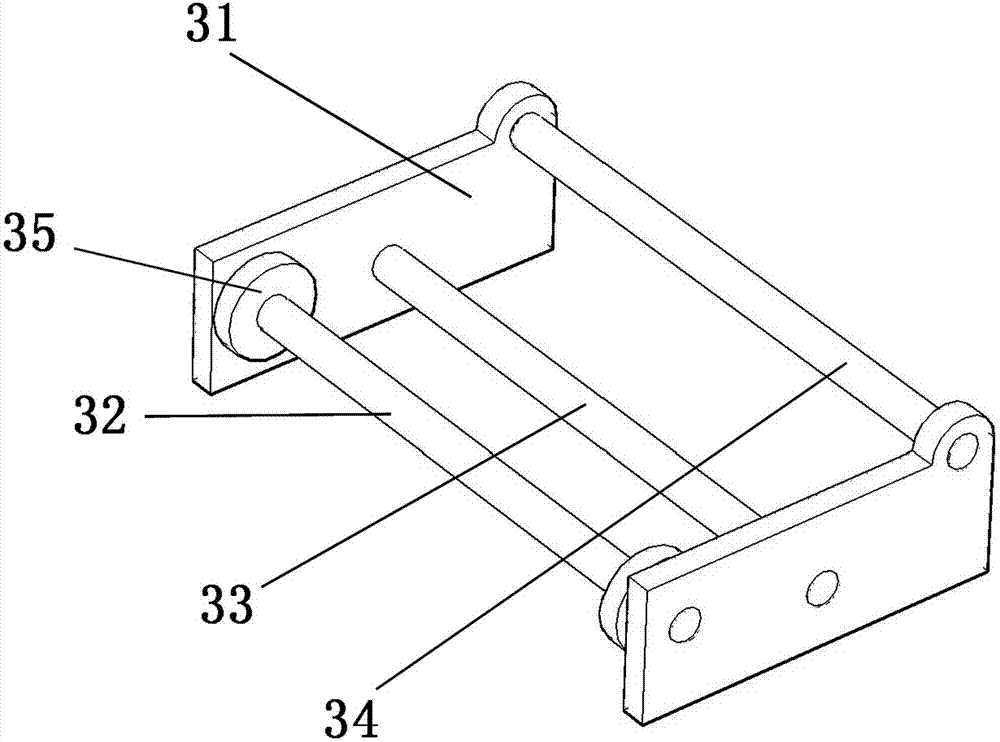

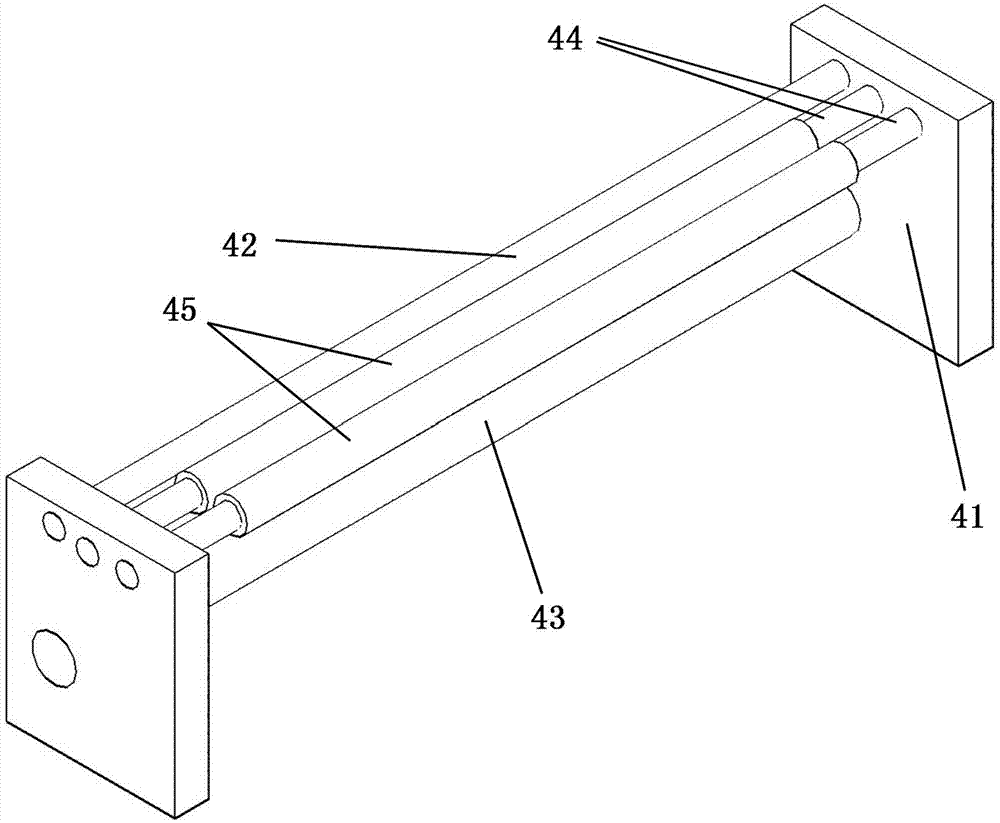

[0023] see Figure 1 to Figure 4 , a wire labeling mechanism according to a preferred embodiment of the present invention, including a frame 1, a feeding mechanism 2, a tape guide mechanism 3, a tape separation mechanism 4, a power mechanism 5, a step monitor 6, and a wire fixing frame 7 , a control module and a folding mechanism 8, the control module is located in the frame 1, the control module is connected with the power mechanism 5, the folding mechanism 8, and the step monitor 6 respectively, the feeding mechanism 2, the strip guiding mechanism 3, and the strip separating mechanism 4 and the power mechanism 5 are sequentially fixed on the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com