Piezoelectric ceramic and piezoelectric device

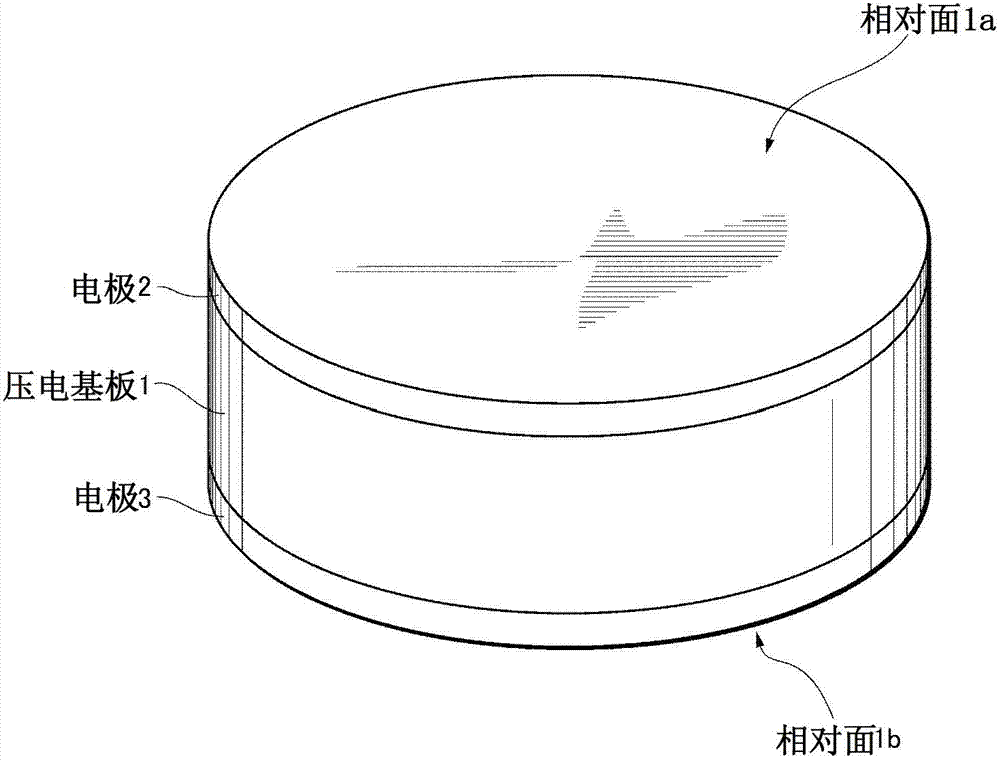

一种压电陶瓷、压电元件的技术,应用在层叠型压电元件领域,能够解决提高、不能得到压电特性、晶粒边界的数量减少等问题,达到抑制空隙、环保性能及生态学优异、压电特性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0062] (Examples 1-3, Comparative Examples 1-2)

[0063] First, prepare sodium carbonate (Na 2 CO 3 ) powder, potassium carbonate (K 2 CO 3 ) powder, lithium carbonate (Li 2 CO 3 ) powder, niobium oxide (Nb 2 o 5 ) powder, tantalum oxide (Ta 2 o 5 ) powder, barium carbonate (BaCO 3 ) powder, zirconia (ZrO 2 ) powder, strontium carbonate (SrCO 3 ) powder, and manganese carbonate (MnCO 3 ) powder or copper oxide (CuO) powder. After these raw materials were sufficiently dried, the respective raw materials were weighed so that the compositions of the piezoelectric ceramics were those of Examples 1 to 3 and Comparative Examples 1 to 2 shown in Table 1, even though the value of m varied.

[0064] After mixing these raw materials in ethanol using a ball mill, they are fully dried in a constant temperature tank at 80-120°C, press-molded, and pre-fired at 750-1050°C for 1-4 hours. The calcined product was pulverized in ethanol using a ball mill, and then dried again to ob...

Embodiment 4~15

[0072] (Examples 4-15, Comparative Examples 3-14)

[0073] so that the general formula (K 1-x-y-w-v Na x Li y Ba w Sr v ) m (Nb 1-z-u Ta z -Zr u )O 3 ...(1) In addition to weighing each raw material so that the values of x, y, z, w, v, and u change, Examples 4-15 and Comparative Examples were produced in the same manner as Examples 1-3. 3 to 14 samples were evaluated and the results are also shown in Table 1.

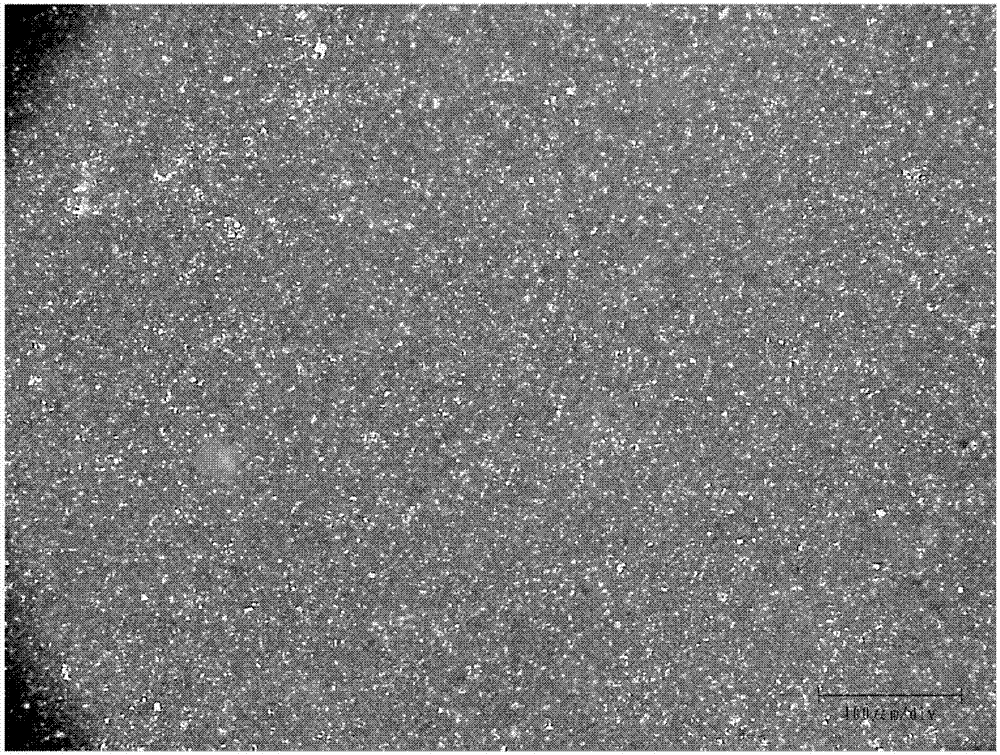

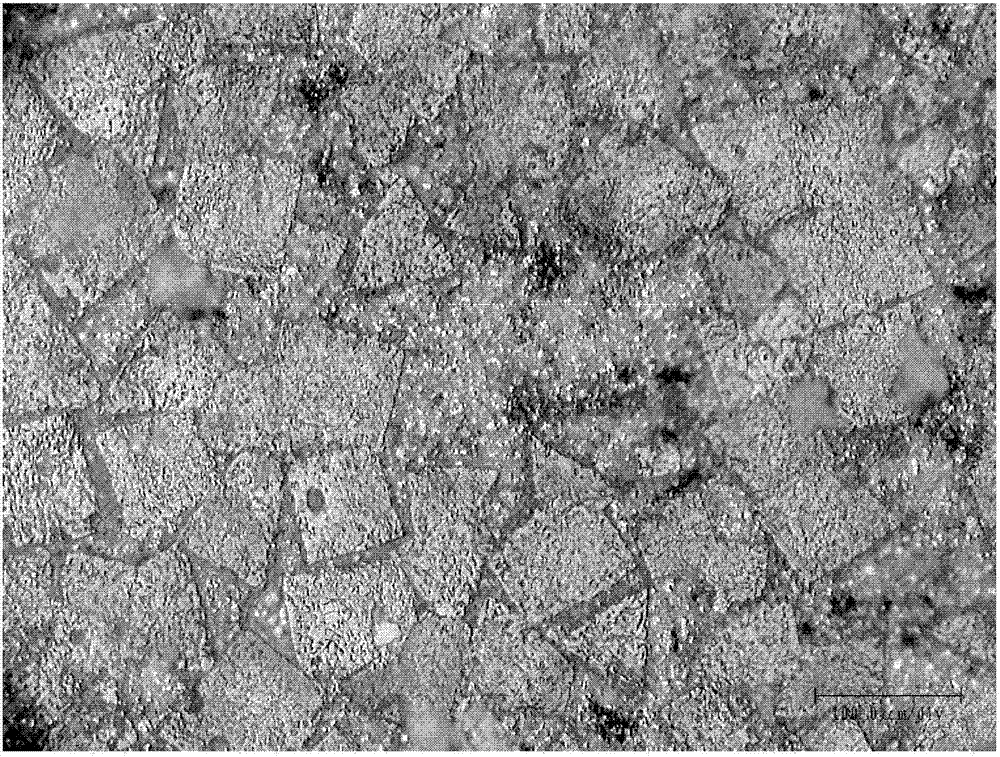

[0074] When x, that is, the amount of sodium (Na) is 0.4 to 0.7, when y, that is, the amount of lithium (Li), is 0.02 to 0.1, and when z, that is, the amount of tantalum (Ta) is 0.3 or less, w That is, when the amount of barium (Ba) is 0.01 or less, when v, that is, the amount of strontium (Sr), is 0.04 to 0.07, and when u, that is, the amount of zirconium (Zr), is 0.04 to 0.07, as shown in the table As shown in 1, abnormal grain growth did not occur, and large values were obtained for εr, kr, and d33. However, as shown in Comparative Examples 3 to 14, k...

Embodiment 16~19)

[0076] In addition, the samples of Examples 16 to 18 were produced and evaluated in the same manner as in Examples 1 to 3, except that the amount of manganese oxide (MnO) as an additive was changed. , and the results are also shown in Table 1. In addition, in Example 19, instead of manganese oxide (MnO), copper oxide (CuO) was weighed and added, and samples were produced and evaluated in the same manner as in Examples 1 to 3. Table 1 also shows the results.

[0077]As shown in Example 16, even when manganese oxide (MnO) was not added, as long as the other compositions were within the prescribed ranges, abnormal grain growth was not observed, and εr, kr, and d33 obtained large values. Furthermore, even when the added amount of manganese oxide (MnO) was 1.0% by mass, abnormal grain growth was not observed, and εr, kr, and d33 obtained large values. However, when the addition amount of manganese oxide (MnO) exceeds 1.0 mass % and reaches 1.5 mass %, although abnormal grain growt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com