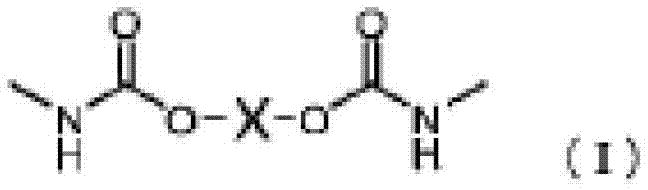

Process for production of polyurethane and uses of polyurethane produced thereby

A technology of polyurethane and polyester polyol, applied in the direction of one-component polyurethane rayon, one-component synthetic polymer rayon, textiles and paper making, etc. , cost reduction, friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

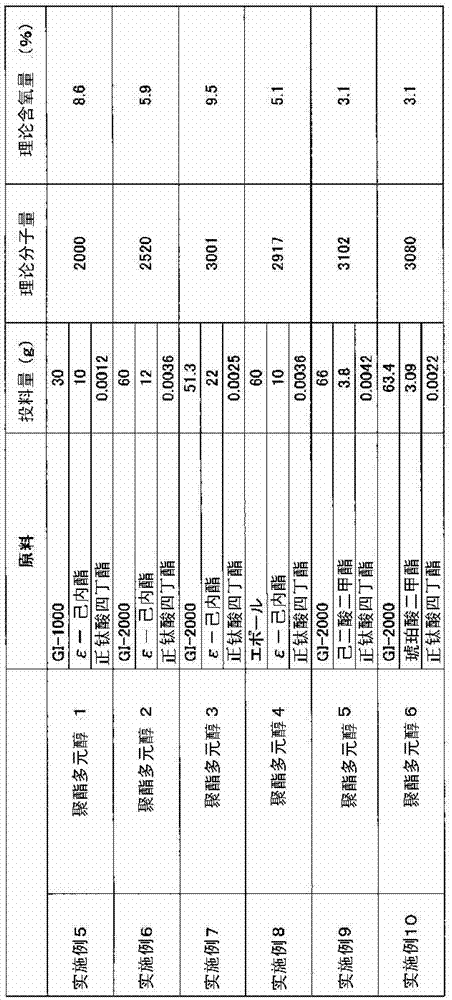

[0213] Hereinafter, although the Example of this invention is demonstrated more concretely, this invention is not limited to these Examples unless the summary is exceeded. In addition, analysis and measurement in the following examples and comparative examples were performed according to the following methods.

[0214]

[0215] The number-average molecular weights of the polyhydroxy hydrocarbon-based polymers and polyether polyols used in the present invention are determined by a hydroxyl value (KOH (mg) / g) measurement method based on the acetylation method of JIS K1557-1:2007.

[0216]

[0217] The molecular weight of the obtained polyurethane or polyurethane urea was measured as follows. A dimethylacetamide solution of polyurethane or polyurethane urea was prepared using a GPC device [manufactured by Tosoh Corporation, product name "HLC-8220" (column: Tskgel GMH-XL (2 root)], and measure the number average molecular weight (Mn) and weight average molecular weight (Mw) in...

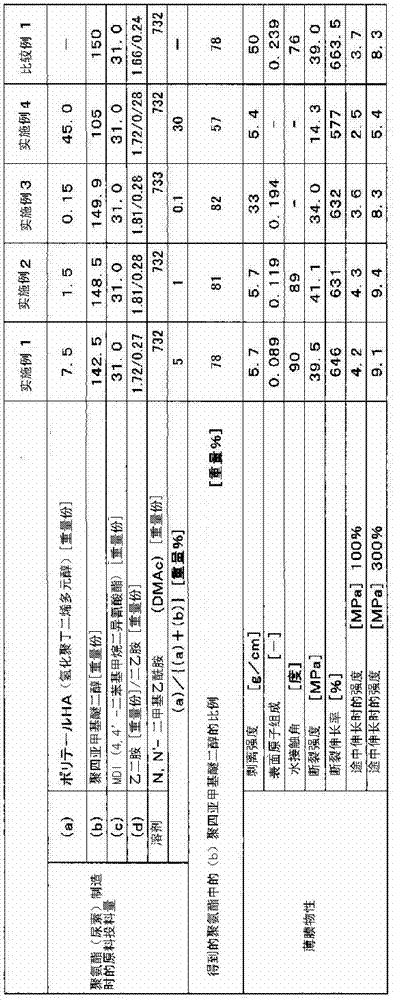

Embodiment 1

[0244]Into a flask with a capacity of 1 L, 142.5 parts by weight of polytetramethylene ether glycol (number average molecular weight calculated from the hydroxyl value: 1968, manufactured by Mitsubishi Chemical Corporation) and hydrogenated Polybutadiene polyol (trade name "Polyter HA" number average molecular weight: 2187, average number of bonded hydroxyl groups per molecule: 1.8) was 7.5 parts by weight, and this mixture was used as a raw material for polyurethane production. The ratio of "Polyter HA" to this mixture was 5% by weight. Then, 31 parts by weight of 4,4'-diphenylmethane diisocyanate (hereinafter, may be abbreviated as "MDI") heated to 40° C. was added. The reaction equivalent ratio of NCO / active hydrogen group (polyether polyol and chain extender) at this time was 1.6. Then, the flask was placed in a 45° C. oil bath, and the temperature of the oil bath was raised to 70° C. over 1 hour while stirring with an anchor-type stirring blade under a nitrogen atmospher...

Embodiment 2

[0250] In Example 1, 148.5 parts by weight of polytetramethylene ether glycol (number-average molecular weight calculated from the hydroxyl value: 1968, manufactured by Mitsubishi Chemical Corporation), which is a raw material for polyurethane production, and "Polyter HA" (number-average molecular weight: 2187, the average number of bonded hydroxyl groups per molecule: 1.8) 1.5 parts by weight (the ratio of "Polyter HA" in this mixture is 1% by weight), and set to ethylenediamine / diethylamine=1.81 / 0.28 (weight ratio), except that, a prepolymer and a polyurethane urea solution were obtained in the same manner as in Example 1.

[0251] After aging the solution overnight at 25° C., the weight average molecular weight and molecular weight distribution were measured by GPC, and the weight average molecular weight was 202,000, and the molecular weight distribution was 2.5. In addition, the ratio of (b) polytetramethylene ether glycol in the obtained polyurethane was 81% by weight. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com