Multi-level freely telescopic rod

A telescopic rod, free technology, applied in the direction of rod connection, connecting components, mechanical equipment, etc., can solve the problems of space limitation, insufficient locking, too tight locking, etc., and achieve long service life, convenient operation, and fast locking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

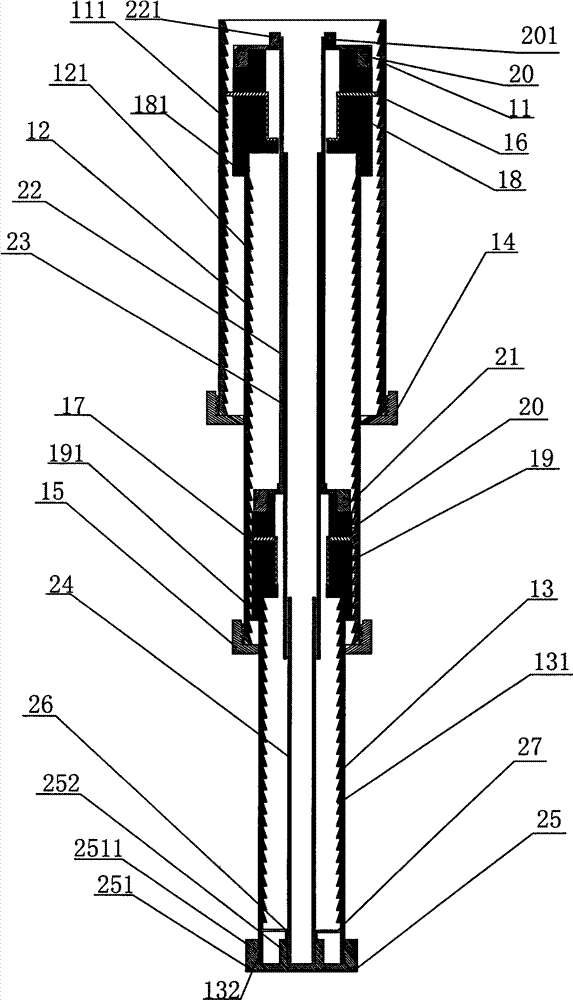

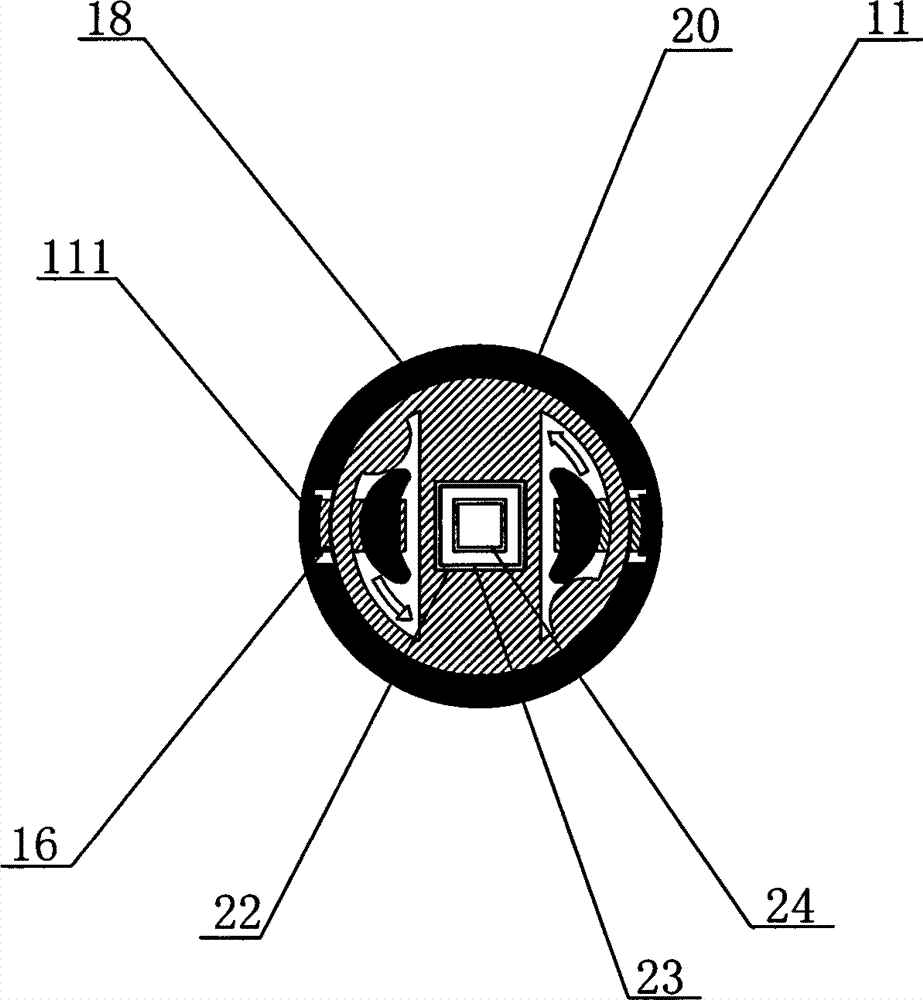

[0041] In order to express the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0042] The multi-stage free telescopic rod provided by the present invention includes n-stage outer tubes, n-stage positioning shrapnels, n-stage positioning parts and n-stage rotating internal pressure parts, wherein n is a natural number; On the top of the locating parts at all levels, the outer tube of the rear stage is movably socketed in the outer tube of the previous stage, and the inner walls of the outer tubes of each level are evenly provided with a plurality of sawtooth levels, and there are gaps on the locating parts of each level. One end of the positioning shrapnel is fixed in the positioning parts of each level one by one, and the other end of the positioning shrapnel of each level penetrates the gaps on the positioning parts of each level and then engages with the sawtooth phases of the outer tubes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com