TDLAS (tunable diode laser absorption spectroscopy) temperature calibration system

A technology for calibrating systems and thermometers, applied in thermometer testing/calibration, thermometers, measuring devices, etc., can solve problems such as material desorption on the surface of temperature sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below with the accompanying drawings ( Figure 1-Figure 3 ) to illustrate the present invention.

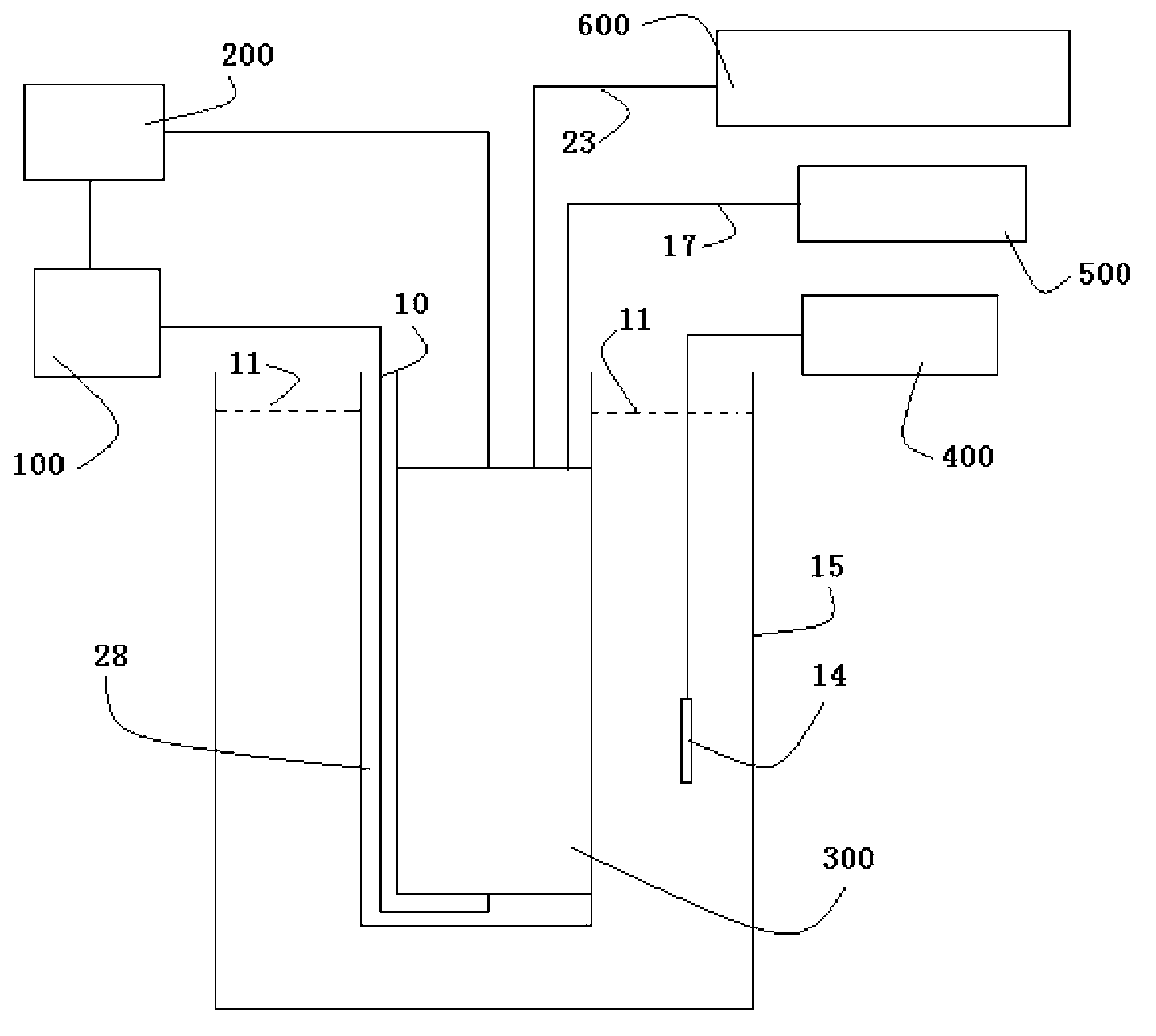

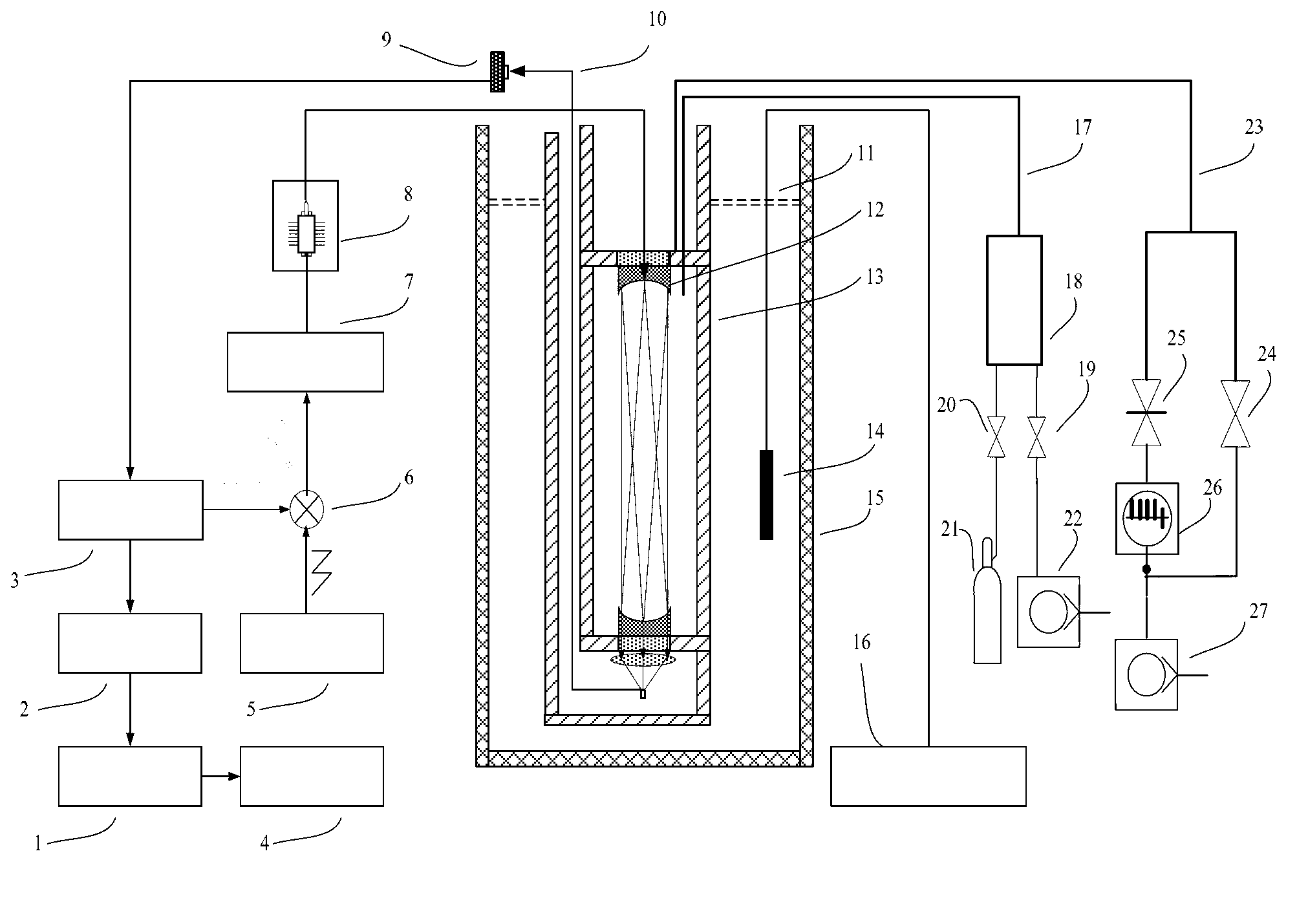

[0021] figure 1 It is a structural schematic diagram of the TDLAS temperature measurement system implementing the present invention. figure 2 It is another structural schematic diagram of the TDLAS temperature measurement system implementing the present invention. Such as figure 1 and figure 2 As shown, the TDLAS temperature calibration system includes a standard sensor temperature measurement system 400 and a calibrated TDLAS temperature measurement system for measuring gas temperature in a vacuum environment. The optical system 300 in the TDLAS temperature measurement system is located in the constant temperature tank 15, so There is a constant temperature liquid between the housing of the optical system 300 and the surrounding wall of the constant temperature tank 15 (it reaches the liquid level 11 of the constant temperature tank), and the standard sensor in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com