Trolley conductor insulator

A technology of insulators and sliding contact wires, which is applied in the field of electrical power supply and distribution, and can solve problems such as easy damage to sliding contact wires, corrosion of screws, and heavy equipment workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

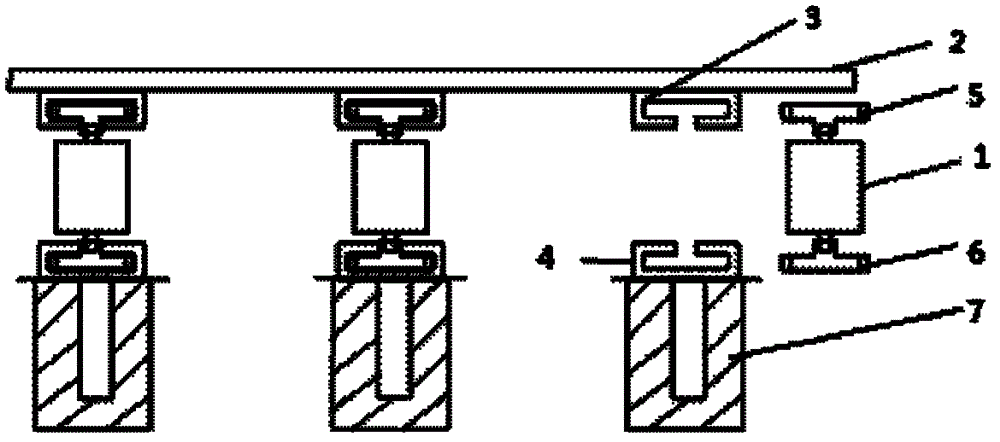

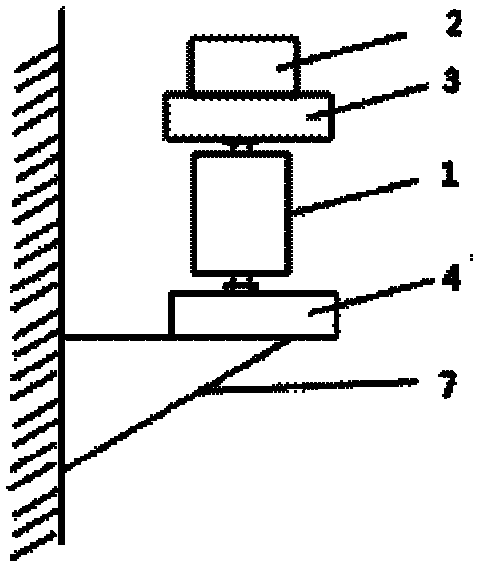

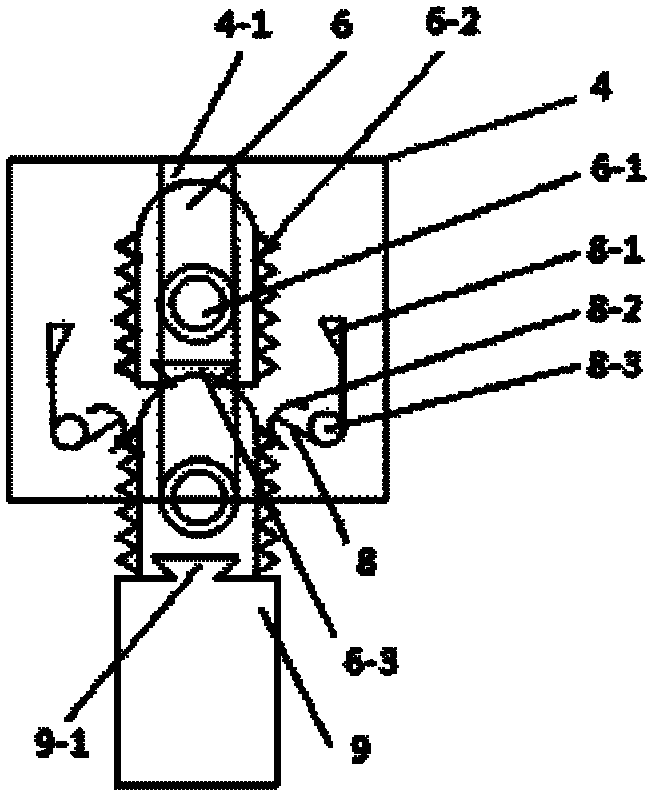

[0016] The trolley line insulator of this embodiment is as figure 1 with figure 2 As shown, the upper and lower ends of the insulating porcelain bottle 1 have threaded heads with opposite rotations respectively, and the cylindrical internal thread bosses 5-1, 6-1 on the lower surface of the upper bottom plate 5 and the upper surface of the lower bottom plate 6 pass through the thread pair. (see Figure 5 )connect. Therefore, when the angular positions of the upper and lower bottom plates are constrained, the distance between the upper and lower bottom plates can be adjusted by twisting the porcelain bottle, which can be used to adjust the pressure on the grinding circuit after the porcelain bottle is installed. The upper and lower bottom plates 5, 6 are respectively inserted in the slots of the upper and lower bases 3, 4 to form a moving pair. The slots of the upper and lower bases 3, 4 respectively have an open notch with a width less than the width of the bottom of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com