Rotating type lamp tube socket structure

A rotary type, lamp technology, applied in the direction of incandescent lamps, discharge lamps, discharge tubes, etc., can solve the problems of difficult operation, difficult assembly action, cumbersome assembly action, etc., and achieve the effect of fast work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

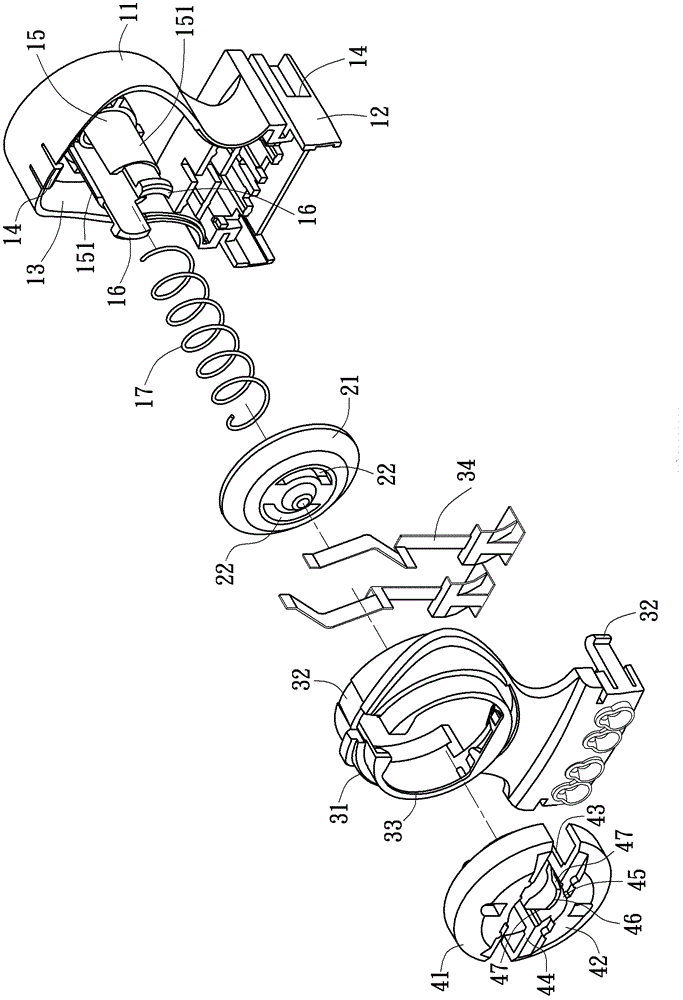

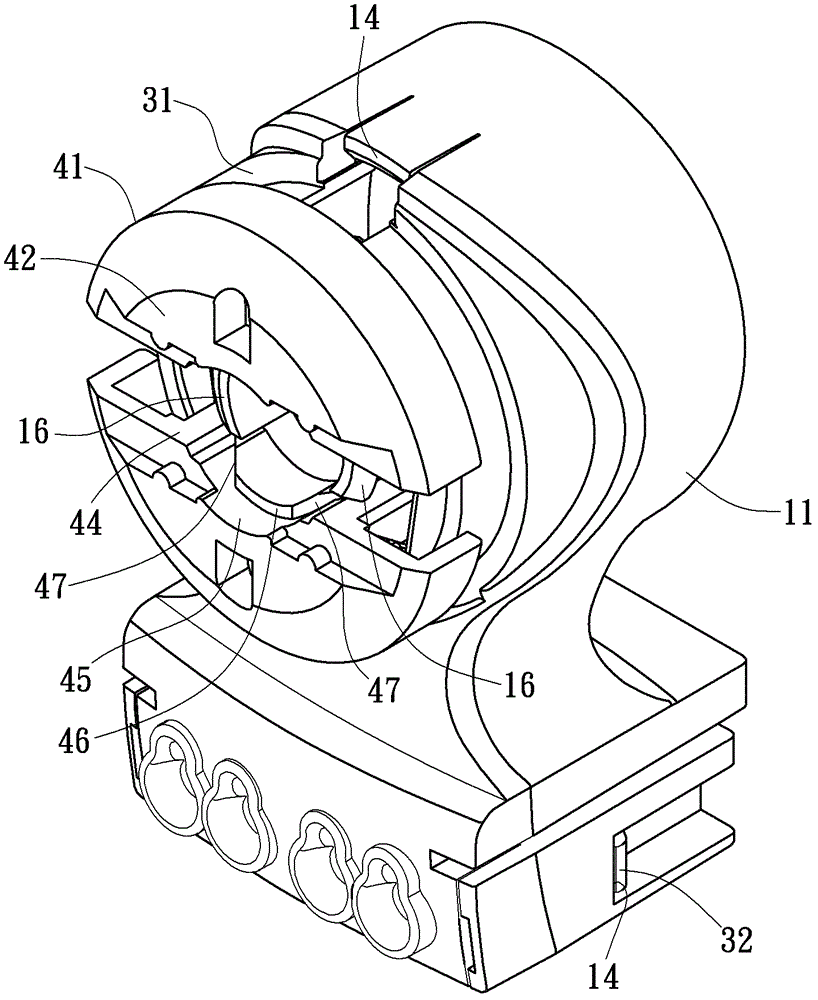

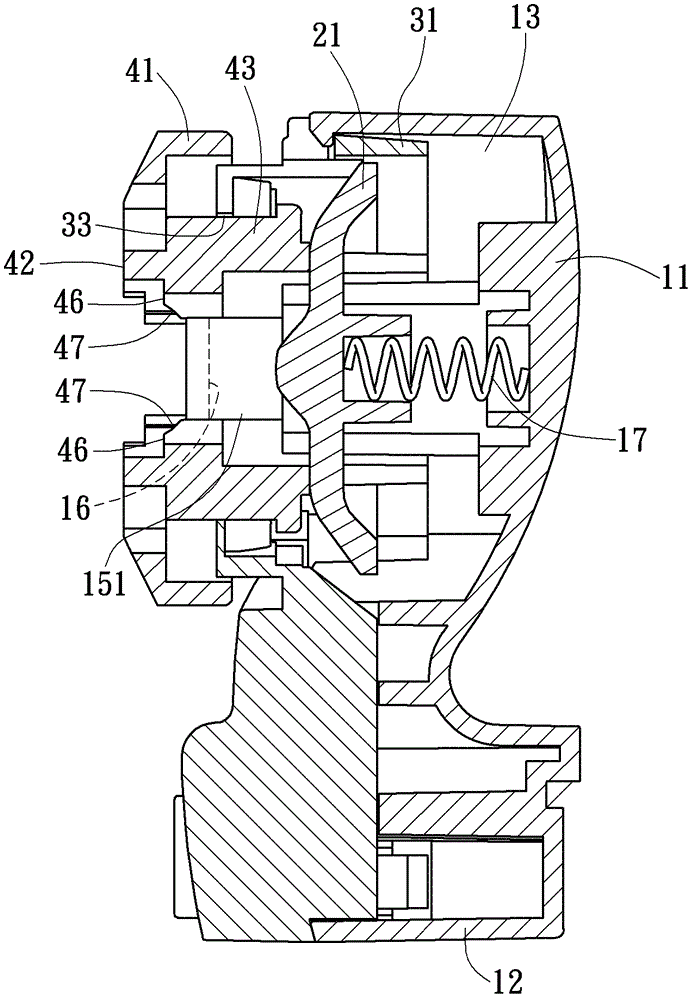

[0031] see Figure 1 to Figure 8 , the present invention provides a rotary lamp socket structure that can be plugged with a terminal 52 of a lamp 51 to form a state of electrical conduction. The rotary lamp socket structure is mainly composed of a base body 11, a top The support member 21, a cover body 31 and a rotating member 41 are composed, wherein:

[0032] The base body 11 has an assembly portion 12 which can be assembled on a lamp base 61, and an accommodating portion 13 extending in the opposite direction of the assembly portion 12, the base body 11 is assembled on it Both sides of the part 12 and the outer side of the housing part 13 are respectively provided with a first plug-in part 14, and a supporting column 15 is extended in the housing part 13. In this embodiment, the supporting column 15 is formed by two side wings 151. As a result, the two side wings 151 are arranged opposite to each other, and each side wing 151 protrudes outward from a top end of a blocking ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com