Method and device for producing yarn

A yarn and twisting device technology, which is applied to spinning machines, textiles and papermaking, and open-end spinning machines, etc., can solve problems such as the inability to achieve stable yarn solidification, yarn breakage, and gradual disappearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

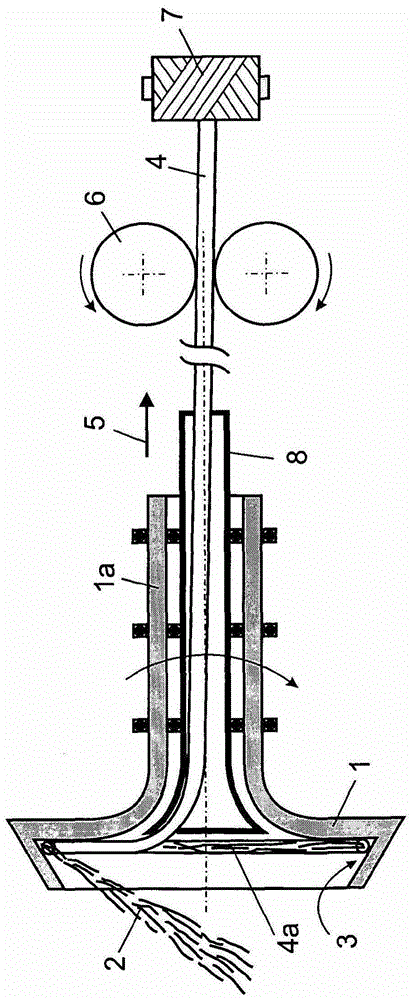

[0062] figure 1 A device according to known prior art is shown. The fiber 2 fed to the wall of the rotor 1 slides into the rotor groove 3 by centrifugal force and is "caught" by the yarn end 4a rotating with the rotor 1 . The yarn 4 is drawn off in direction 5 via the rotor shaft 1a. Yarn 4 is drawn off via draw-off roller 6 and wound onto bobbins 7 . For drawing, these rollers 6 are rotated towards each other, so that the yarn 4 arranged between the rollers is conveyed.

[0063] In this case, a yarn feeder 8 is provided rotatably inside the rotor shaft, through which the yarn 4 is drawn inside. At this moment, the yarn 4 rolls on the inner wall of the yarn feeder 8 and obtains false twist, but only in the area of the rotor 1 .

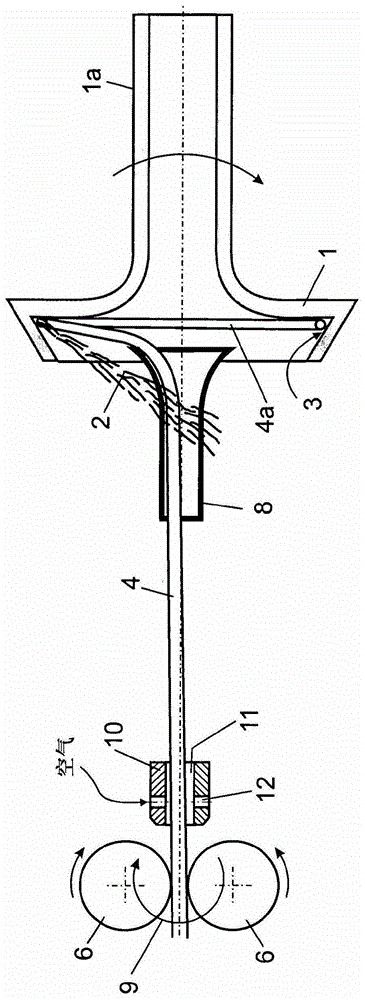

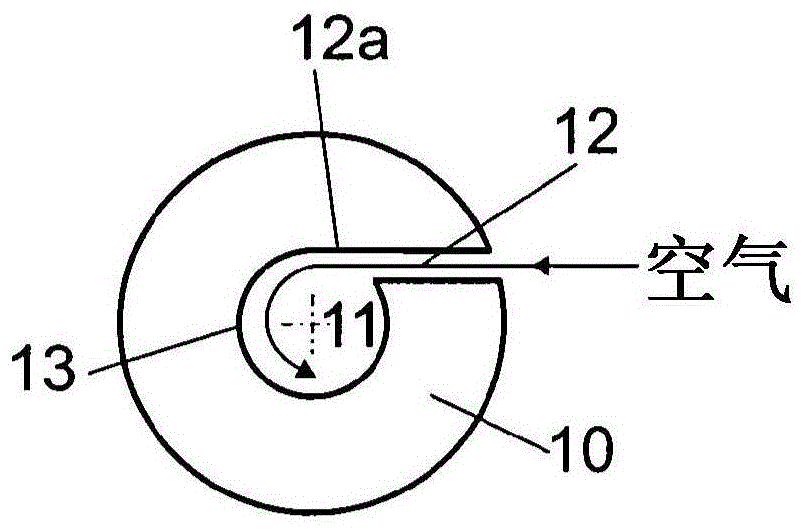

[0064] figure 2 shows an arrangement according to the invention, where the fibers 2 fed to the rotor 1 are merged into the yarn 4 in the rotor groove 3 and the yarn 4 passes through the feed nozzle 8 along the opposite direction to the rotor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com