Air conditioner, anti-detaching pipe joint and assembly

A detachable pipe and pipe joint technology, which is applied to non-detachable pipe connections, pipes/pipe joints/fittings, threaded connections, etc., can solve the problems of unobvious product advantages, limited after-sales installation, and reduced use range, etc., to achieve Improve refrigerant leakage, reduce installation and maintenance costs, and facilitate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

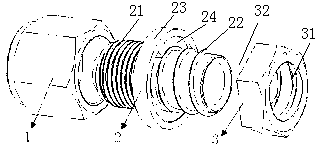

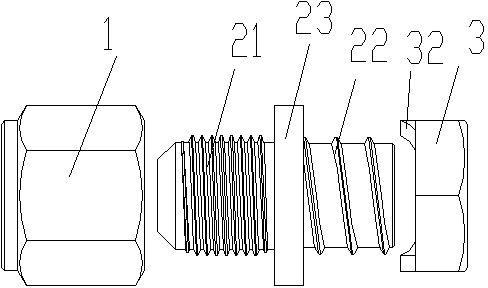

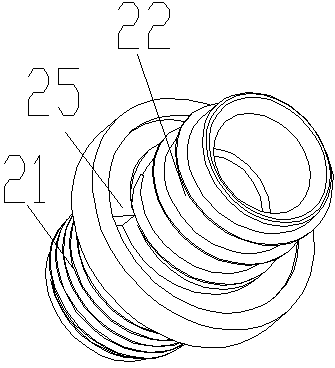

[0027] see figure 1 and figure 2 The anti-disassembly pipe joint assembly of the present invention includes an anti-disassembly pipe joint and a union nut 1, and the anti-disassembly pipe joint includes a pipe joint body 2 and an auxiliary nut 3, wherein the pipe joint body 2 and the auxiliary nut 3 are two independent Parts, the two ends of the pipe joint body 2 are provided with threads 21 and 22, wherein one end thread 22 is matched with the thread 31 of the auxiliary nut 3, and the other end thread 21 is matched with the thread of the union nut 1.

[0028] The auxiliary nut 3 is combined with one end of the pipe joint body 2. When a clockwise torque is applied to the auxiliary nut 2, the two parts of the independent pipe joint body 2 and the auxiliary nut 3 can rotate synchronously, which can ensure that the pipe joint body 2 and the union nut 1 pass through. Threaded connection to connect the evaporator and connecting pipe. When the counterclockwise torque is applied t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com