Preparation method of film bulk acoustic resonator with electrodes provided with double-ring and bridge-shaped structures

A thin-film bulk acoustic wave, double-ring technology, applied in electrical components, impedance networks, etc., can solve the problem of further breakthroughs in thin-film bulk acoustic wave resonators, etc., to improve the frequency and Q value, the electromechanical coupling coefficient does not change much, and improve the Q effect of value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with accompanying drawing.

[0040] A method for preparing a film bulk acoustic resonator with electrodes provided with a double ring and a bridge structure, the specific steps are as follows:

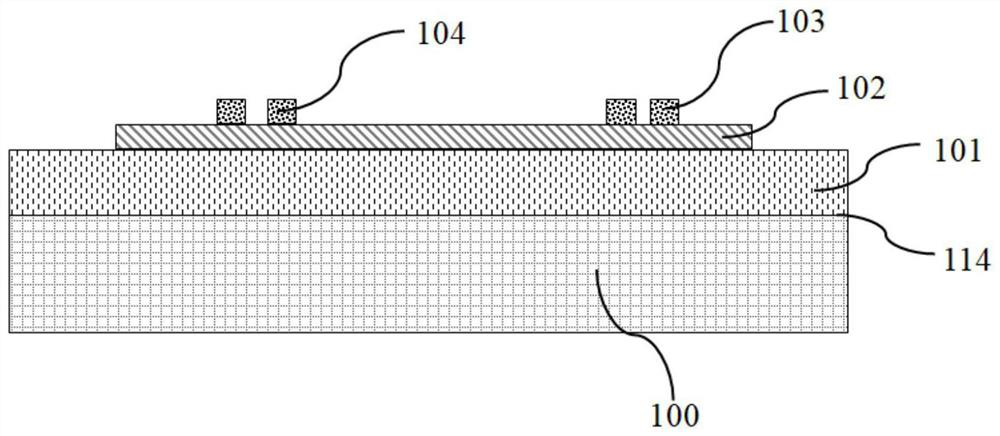

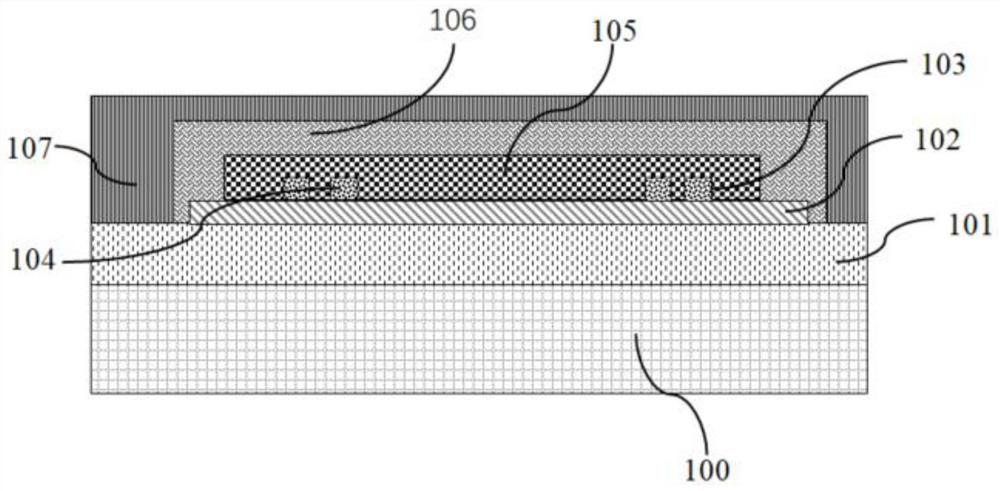

[0041] S1: if figure 1 As shown, the substrate 100 is ultrasonically washed; the peeling layer 114 is deposited on the surface of the substrate 100 by metal organic compound chemical vapor deposition (MOCVD); the material of the peeling layer 114 is GaN; The electrical layer 101 has a thickness of 10nm-4000nm. Next, metal is deposited on the surface of the piezoelectric layer 101 by thermal evaporation or magnetron sputtering, and patterned by plasma or wet etching to form the bottom electrode 102 . Finally, metal is deposited on the surface of the lower electrode 102 by thermal evaporation or magnetron sputtering, and patterned by plasma or wet etching to form the inner annular protrusion 104 and the outer a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com