variable diameter orifice flowmeter

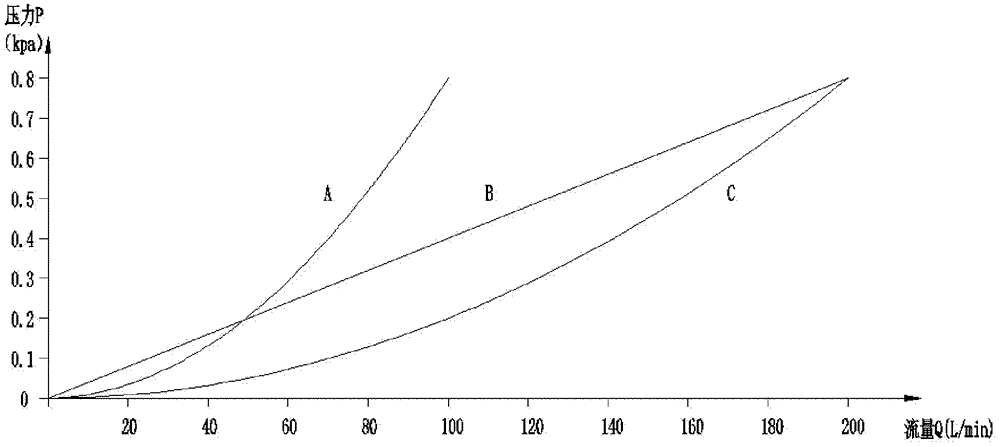

A flowmeter and orifice technology, which is applied to the volume/mass flow generated by mechanical effects, and the direction of fluid flow detection by measuring differential pressure. Achieve the effect of large flow detection range, slow resistance growth rate, easy production and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

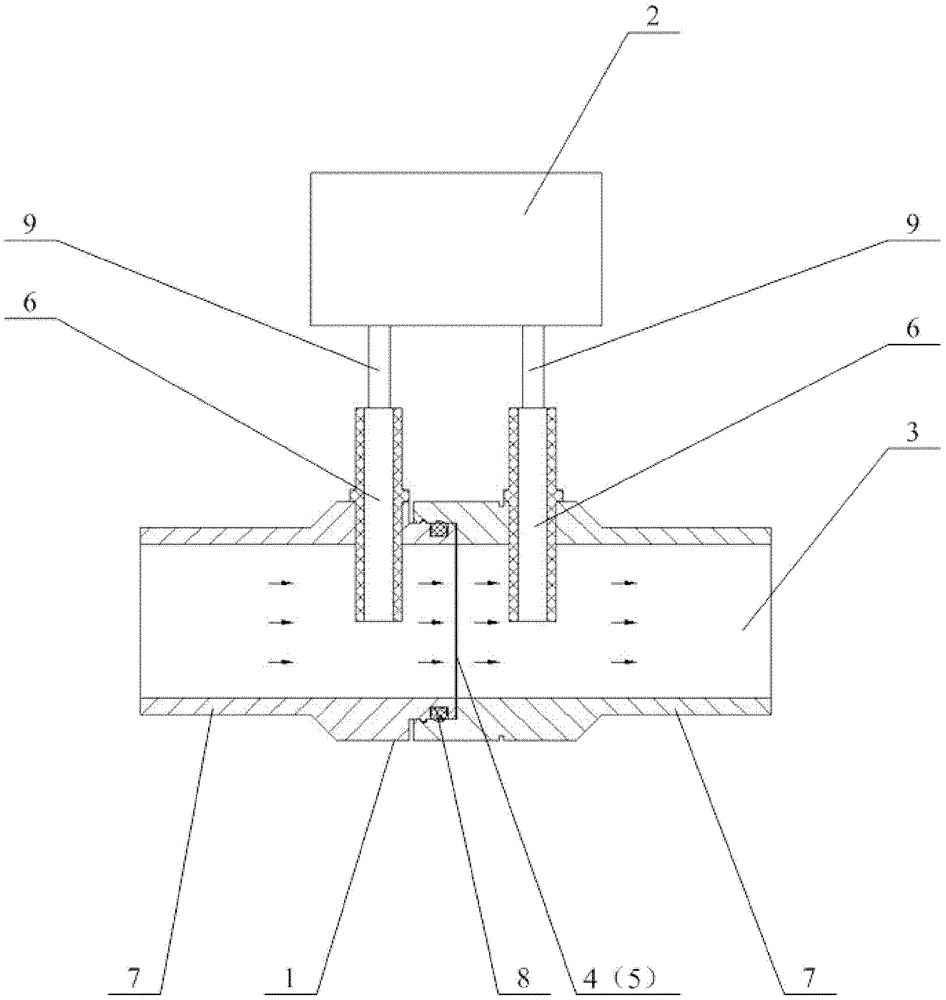

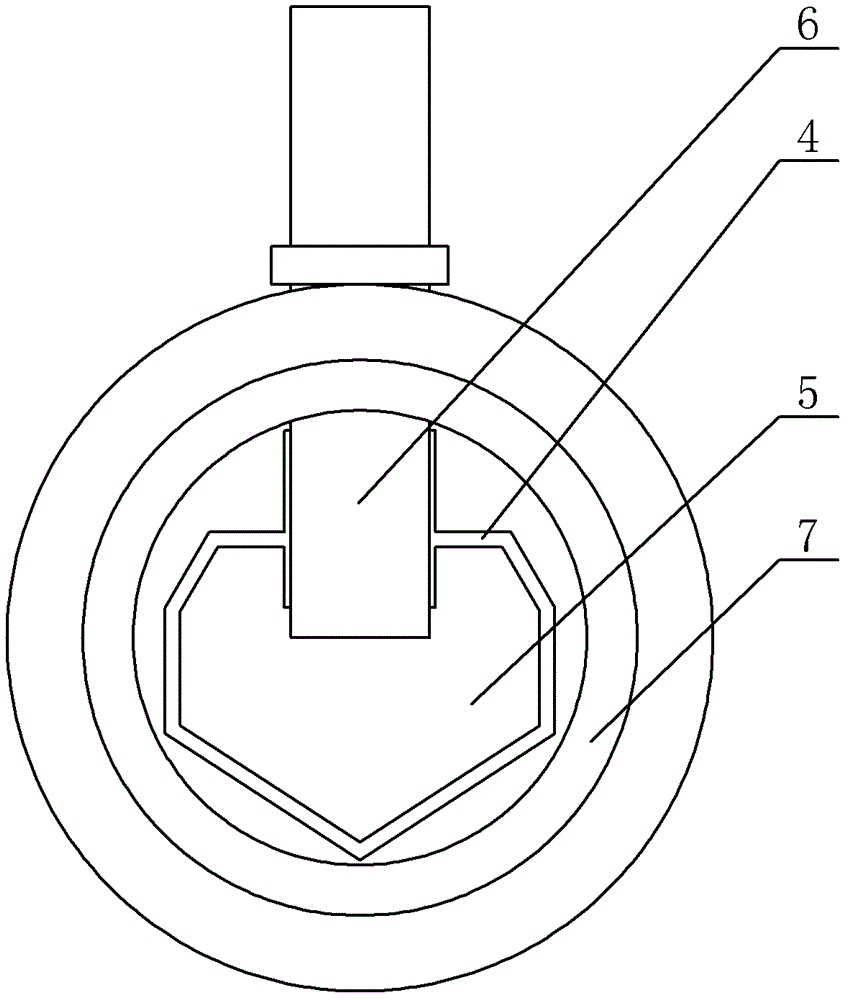

[0026] Such as figure 2 and 3 As shown, in a preferred embodiment of the present invention, the variable-diameter orifice flowmeter includes a throttling device 1 and a flow sensor 2, and the throttling device 1 is provided with a pipeline 3 inside, and the throttling device 1. It is composed of two main bodies 7 that are installed together; the two main bodies 7 are installed with a socket and a slot structure, and the socket and the slot are sealed by bonding, and an O-ring is provided at the sealing place 8. The pipeline 3 is provided with an orifice 4, and the cross-sectional area of the orifice 4 is smaller than the cross-sectional area of the pipeline 3. Specifically, the orifice 4 is arranged at the junction of the two main bodies 7; A movable diaphragm 5 is arranged in the orifice 4, and the upper end of the diaphragm 5 is fixedly connected with the upper end of the orifice 4, and there is a gap between the diaphragm 5 and the orifice 4, and the two main bodies 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com