Method for Obtaining Resistance of Finned Tube Array of Waste Heat Boiler

A waste heat boiler and acquisition method technology, applied in steam boilers, lighting and heating equipment, instruments, etc., can solve problems such as ineffectiveness, difficult equivalent simulation, and inaccurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

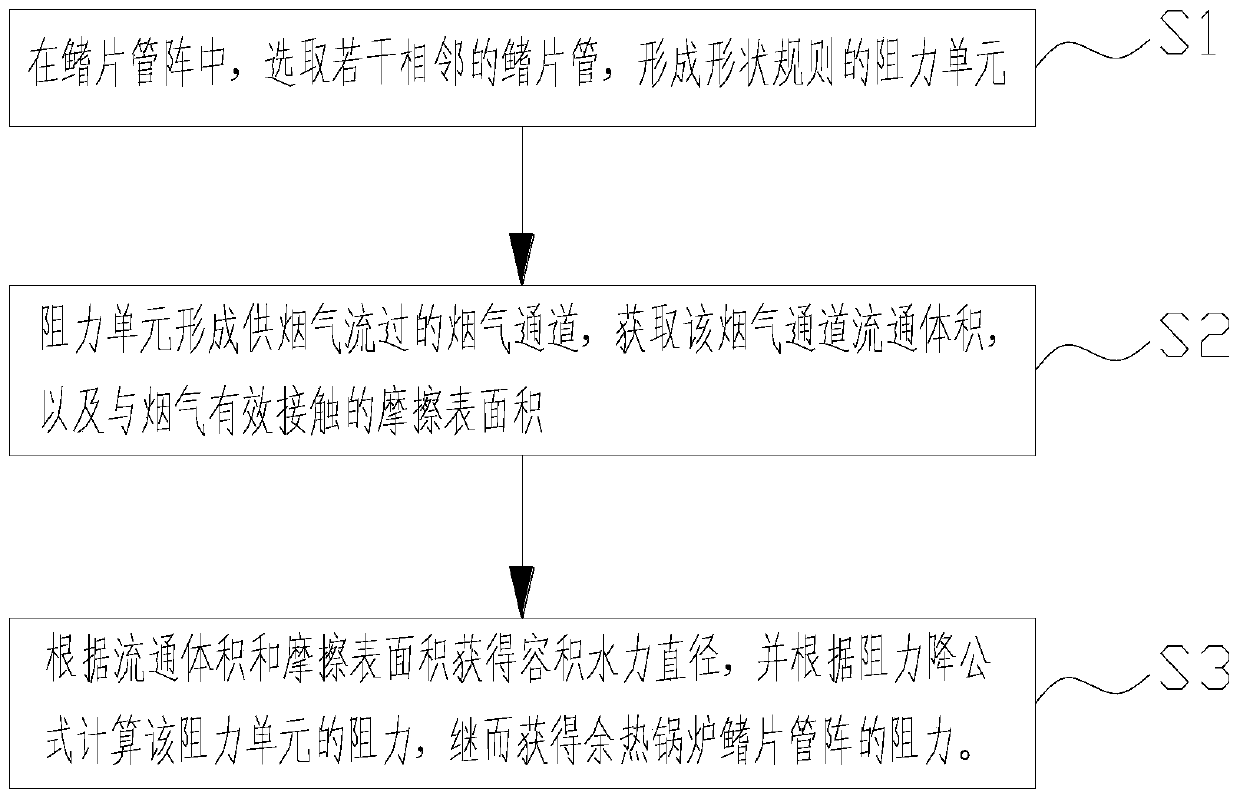

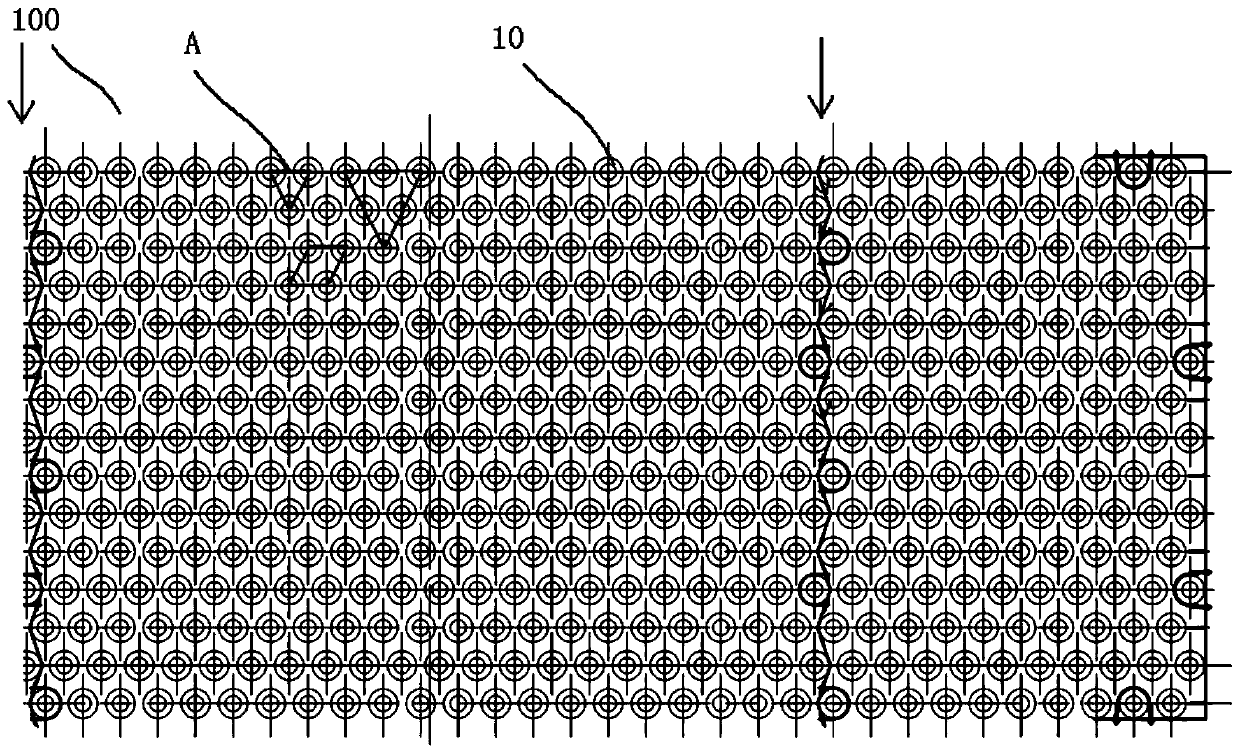

[0044] Please refer to figure 2 , figure 2 It is a flow chart of a specific embodiment of the resistance acquisition method of the waste heat boiler fin tube array provided by the present invention; image 3 It is a schematic diagram of selecting a resistance unit in a fin tube array, in which the resistance unit is indicated by a black line frame, and the direction of the arrow indicates the flow direction of the smoke.

[0045] can be combined figure 1 It is understood that the finned tube array 100 in the waste heat boiler includes multiple rows of finned tubes 10, and each row has several finned tubes 10. The structure of the entire finned tube array 100 is relatively complicated, and it is difficult to establish ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com