Seamed egg detection device

A technology for detection devices and actuators, which is applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, which can solve the problems of longer processing time for crack judgment, failure to detect cracks, and different vibration sounds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

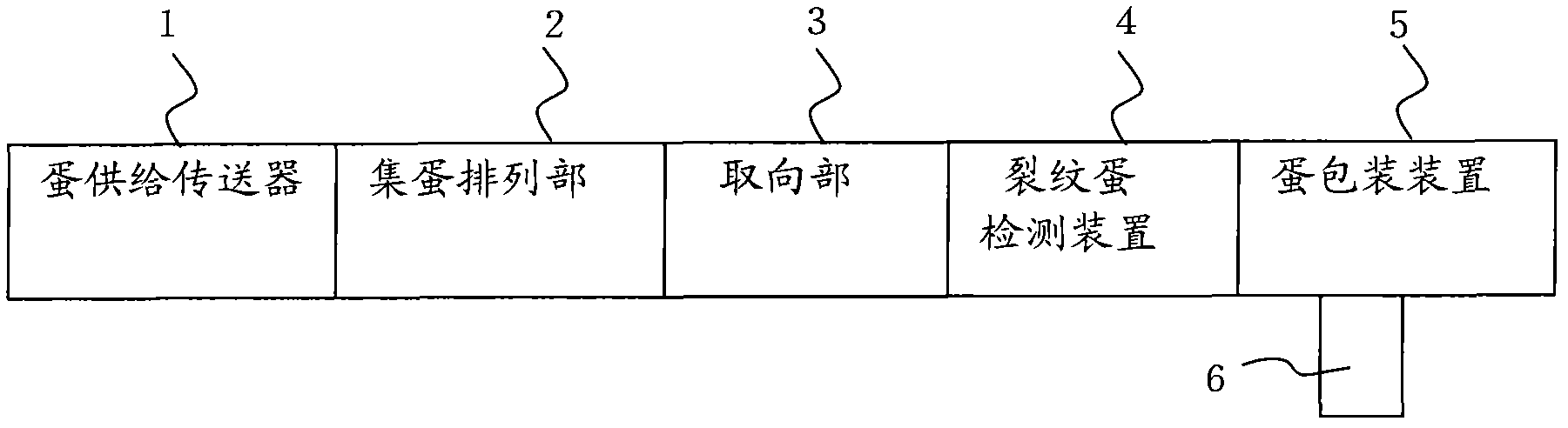

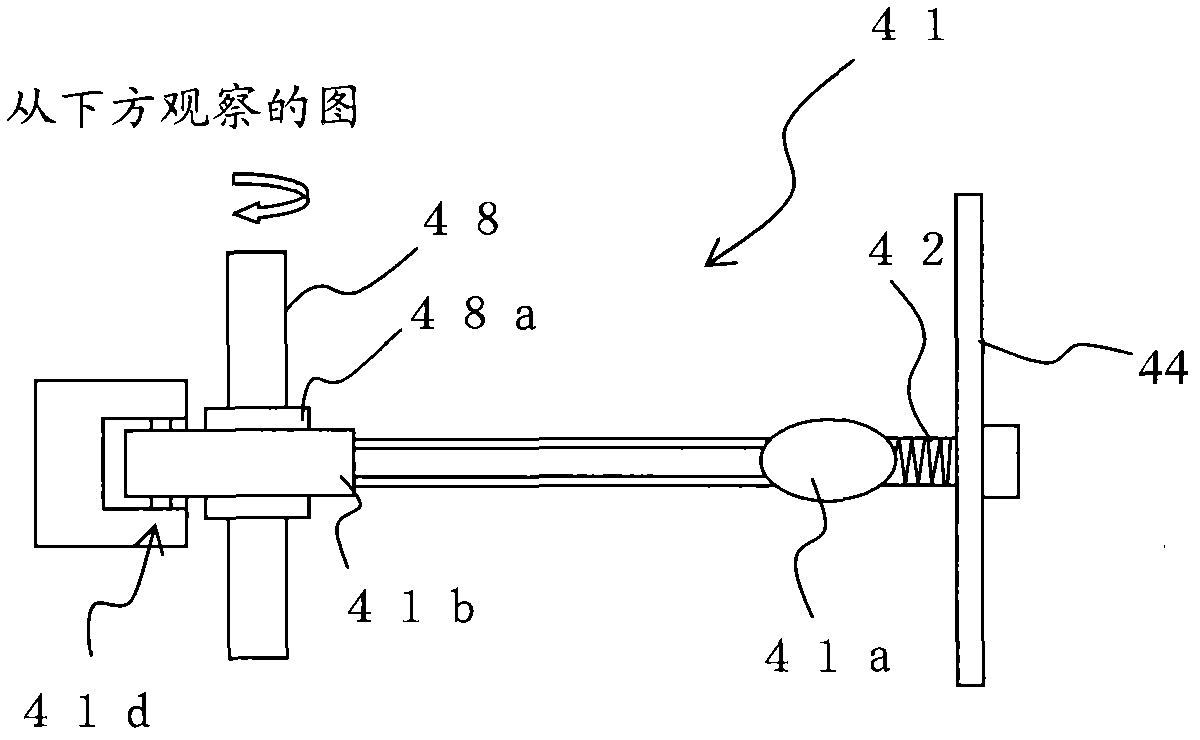

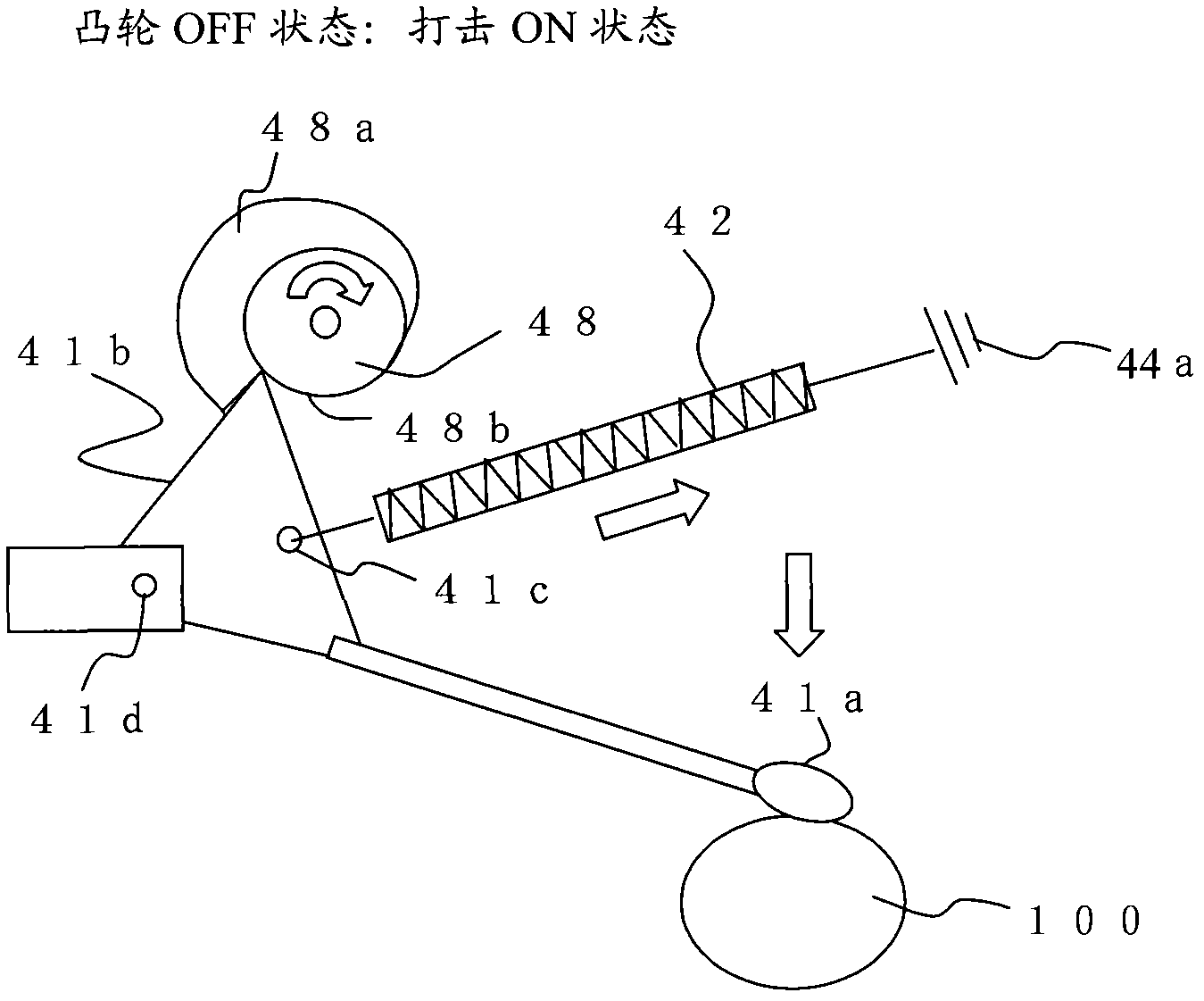

[0049] Embodiments of the cracked egg detection device of the present invention will be described with reference to the drawings. figure 1 It is a diagram conceptually showing the overall configuration including the cracked egg detection device. As an apparatus configuration on the upstream side of the cracked egg detection device, an egg supply conveyor 1 , an egg collection arrangement unit 2 , and an orientation unit 3 are provided. Eggs conveyed from the hen house by the egg supply conveyor 1 are divided into predetermined rows n (for example, 6 rows) by the egg collection arrangement unit 2 . Then, it is sent to the orientation section 3, so that the orientation of the pointed end and the blunt end of the egg are consistent. The egg conveyor 51 in the cracked egg detection device 4 sends the eggs downstream while rotating them. During conveyance to the downstream side, the cracked egg detection device 4 hits the egg to determine whether there is a crack. Details will b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com