Oil return filtering device and filtering method for supporting roll lubricating system of rolling mill

A lubricating system and back-up roll technology, applied in the direction of rolls, metal rolling, metal rolling, etc., can solve the problems of small adsorption area, complicated disassembly and cleaning of filter devices, and limited magnetic force of magnetic rods, so as to ensure the filtering effect and clean And the effect of simple and convenient replacement and guaranteed performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] With reference to the accompanying drawings, the specific implementation of the present invention will be further described in detail through the description of the best embodiment.

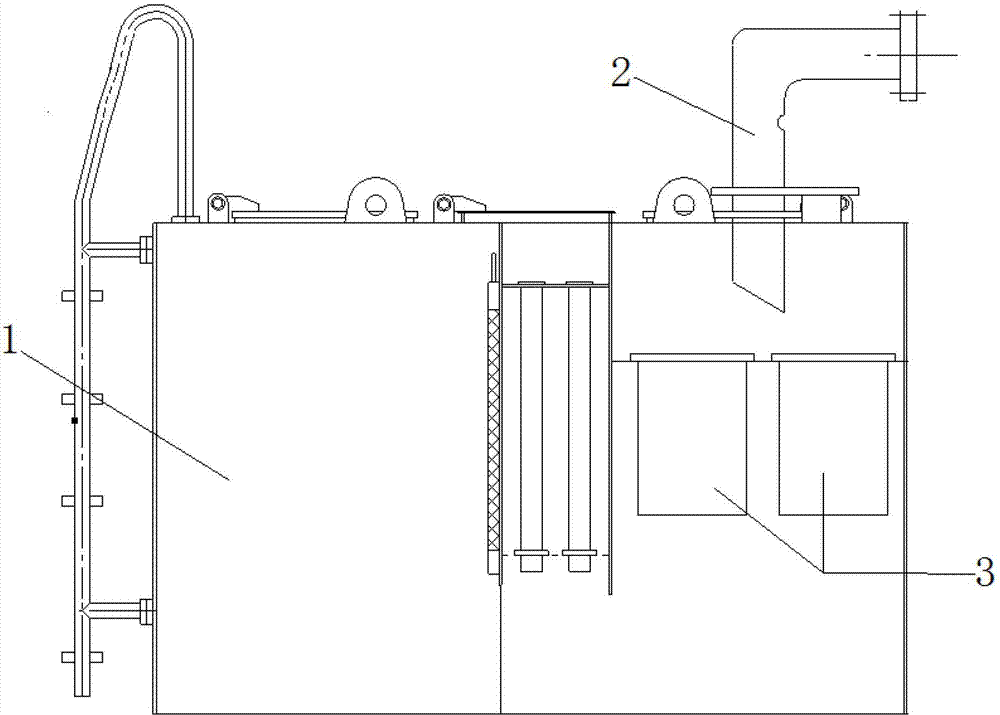

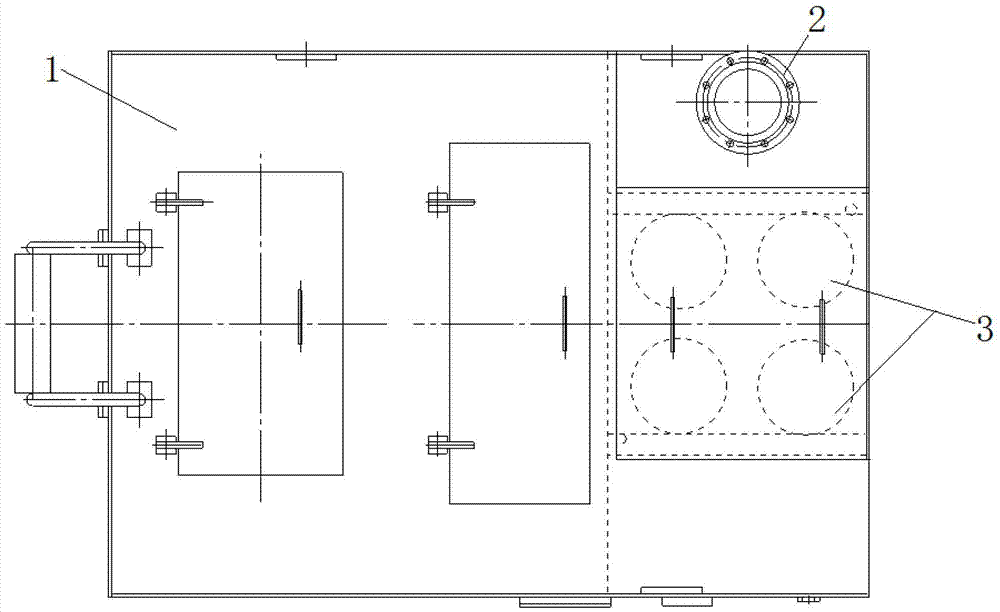

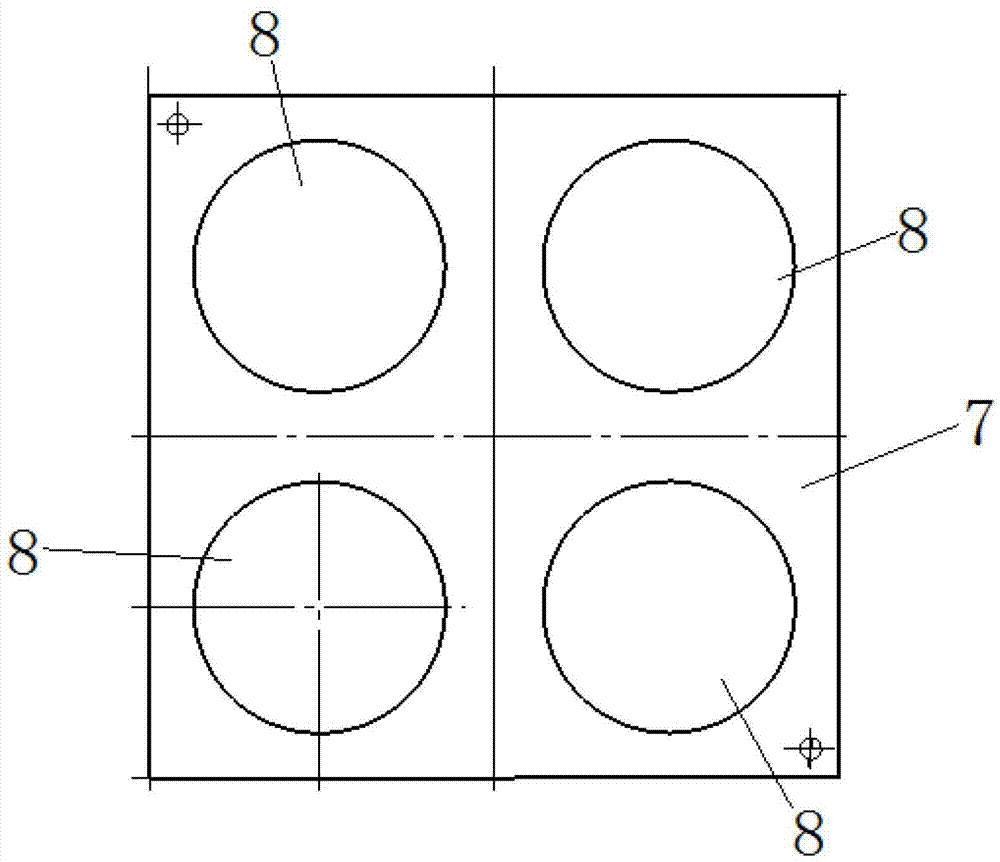

[0032] Such as figure 1 and figure 2 As shown, the back-up roller lubrication system of the rolling mill is equipped with an oil return filter device. The support roller lubrication system includes an oil tank 1. An oil outlet pipe and an oil return pipe 2 are connected to the oil tank 1; 2. The filter 3 below the outlet is composed of the filter 3 facing the outlet of the oil return pipe 2. The lubricating oil flowing from the oil return pipe 2 is filtered by the filter 3 and then enters the oil tank 1 for recycling, which can effectively enhance the filtering effect; Figure 4 and Figure 5 As shown, the filter 3 consists of a disk assembly 4 that absorbs iron in the oil, a metal filter 5 that is set on the outside of the disk assembly 4 to absorb large non-metallic impurities that cannot be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com