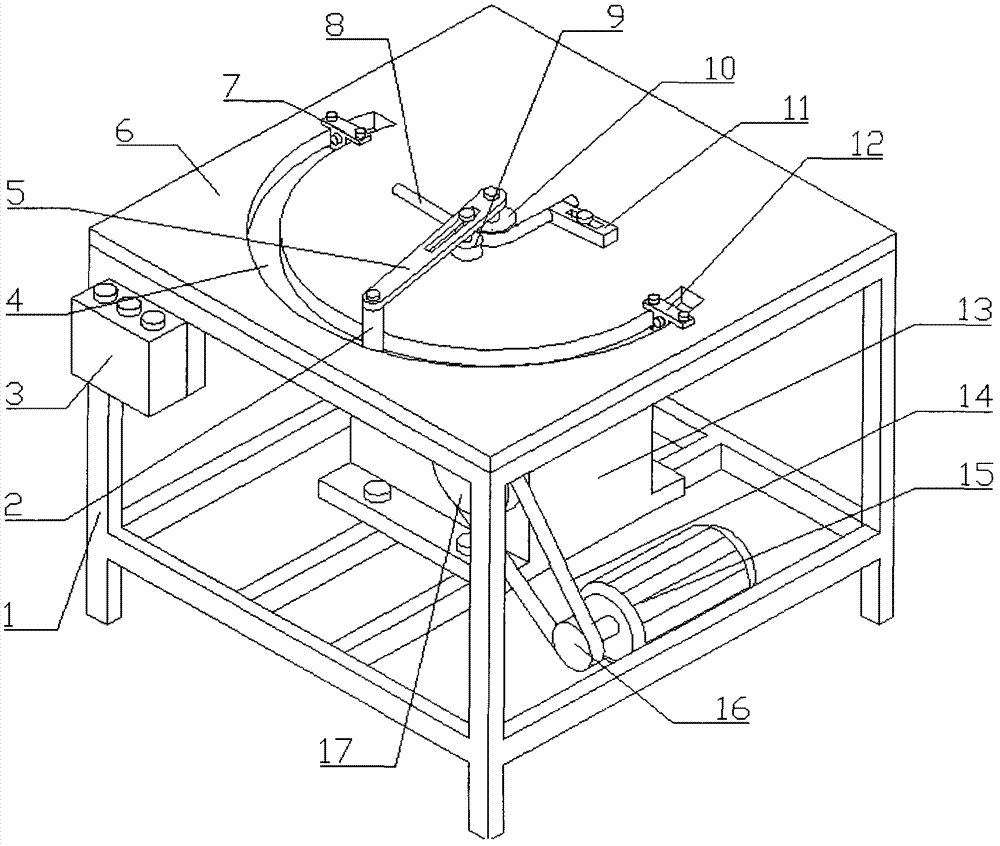

U-shaped bolt bending device

A bending device and bolt technology, which is applied in the field of hydraulic device manufacturing, can solve problems such as difficult control of the opening angle, asymmetrical lengths on both sides, and inability to achieve precision, etc., to achieve the effects of ensuring strength, solving large errors, and avoiding distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

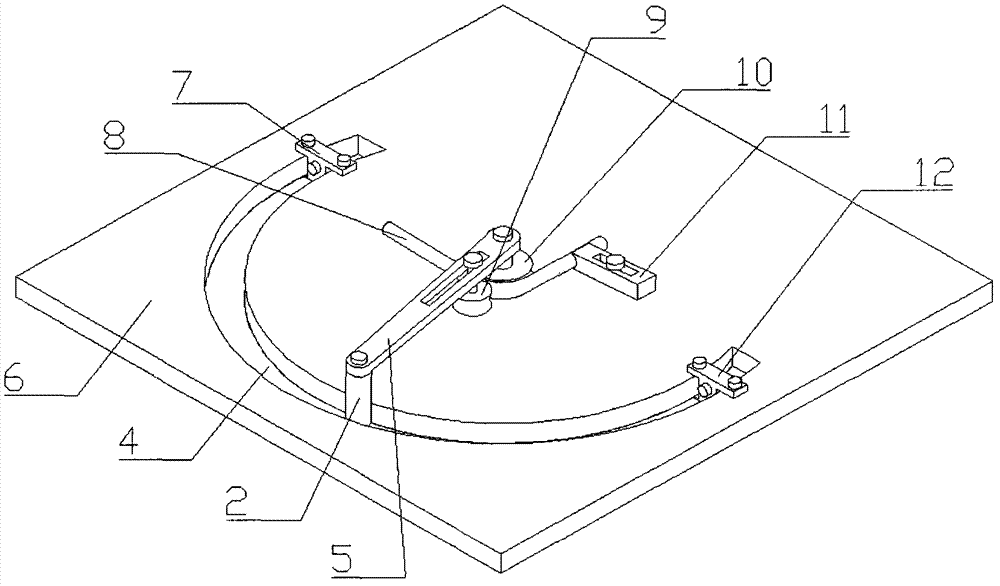

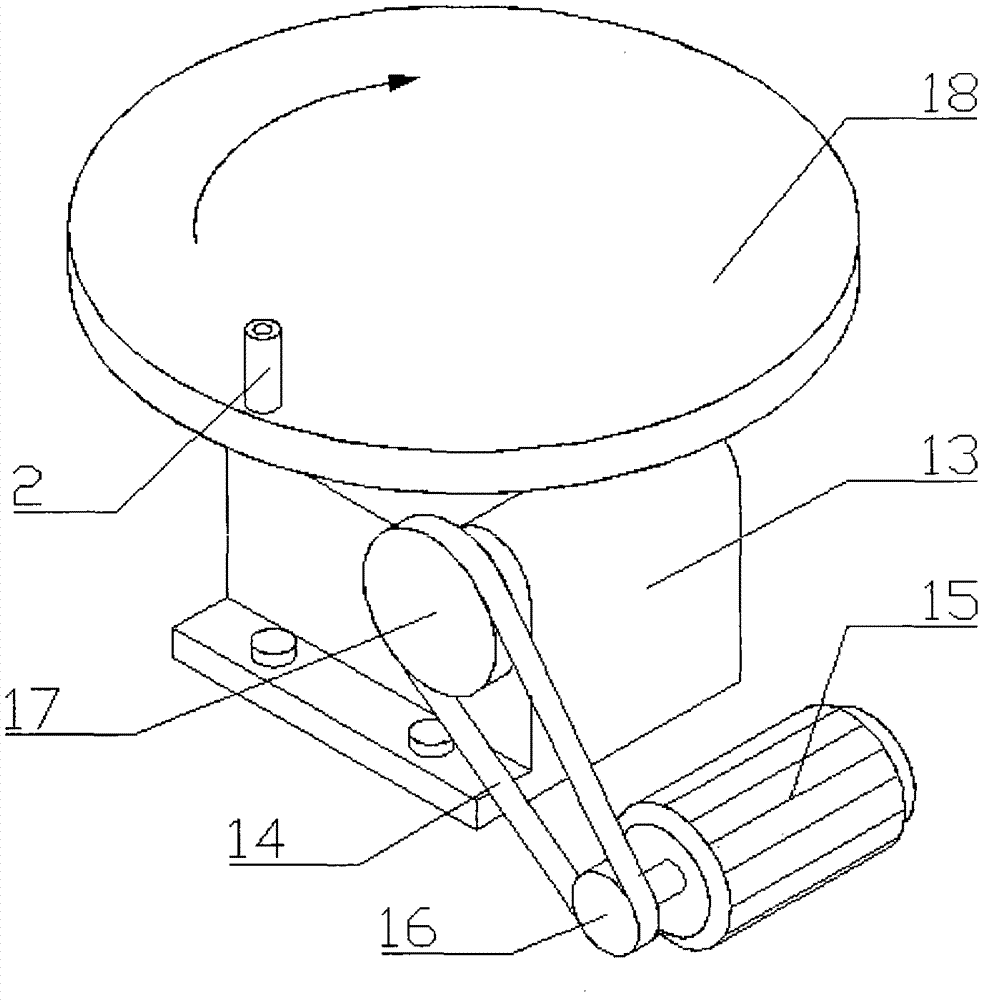

[0041] 1. Determine the type of U-shaped bolt to be processed, select the type of the coil wire wheel 10 and fix it, adjust the workpiece fixing ejector rod 11, select a suitable angle and length and fix it, and place the straight bolt on the coil wire wheel 10 and the anti-wheel 9 In the middle, one end is placed in the groove of the workpiece fixing push rod 11, and the position of the anti-wheel 9 is adjusted so that the workpiece 8 is fixed under the positioning of the anti-wheel 9, the wire coil wheel 10 and the workpiece fixing push rod 11, and the anti-wheel 9 is fixed. Adjust the position of the limit contact reverse switch 7 and the limit contact stop switch 12, select the angle according to the processing requirements, determine the position of the limit switch slider and tighten the bolts at both ends of the slider to fix it.

[0042]2. Turn on the power, press the controller 3, the U-shaped bolt bending device starts to work, the motor 15 drives the worm gear reduce...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap