Hoisting system with overweight pre-warning function

A technology to improve the system and function, applied in the direction of hoisting device, clockwork mechanism, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

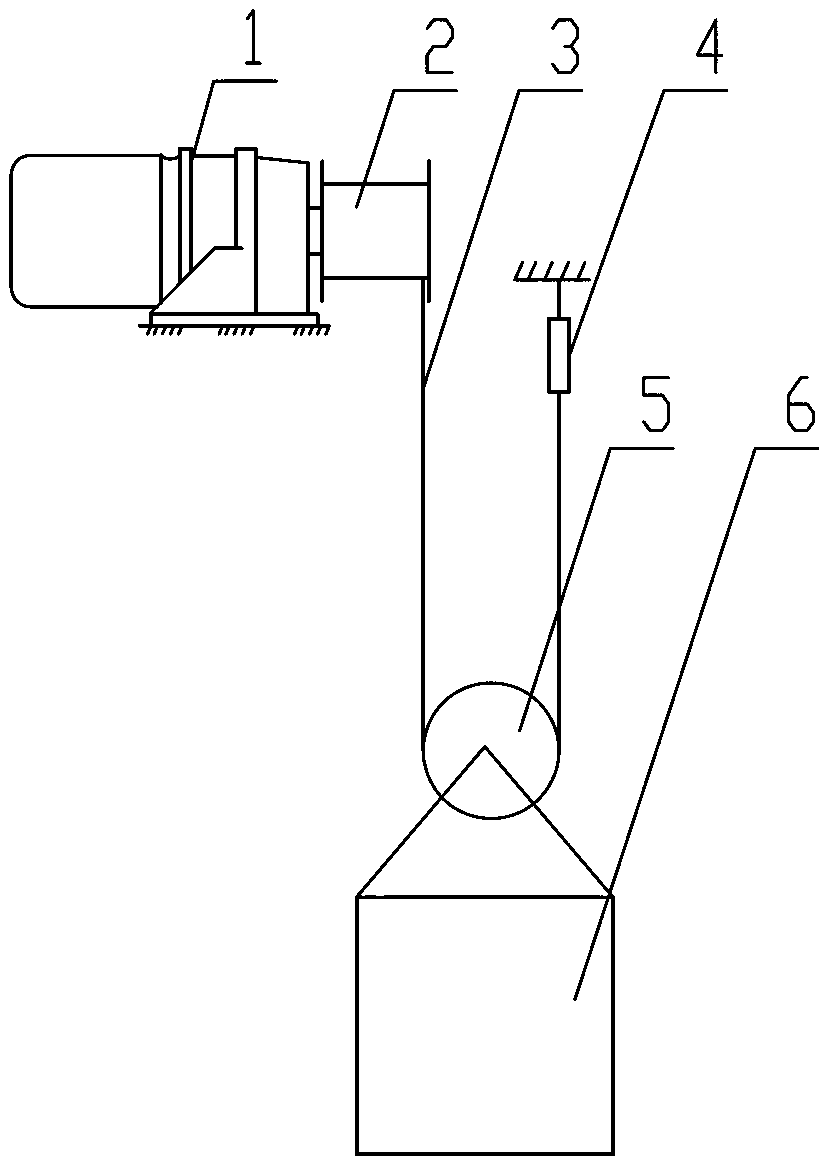

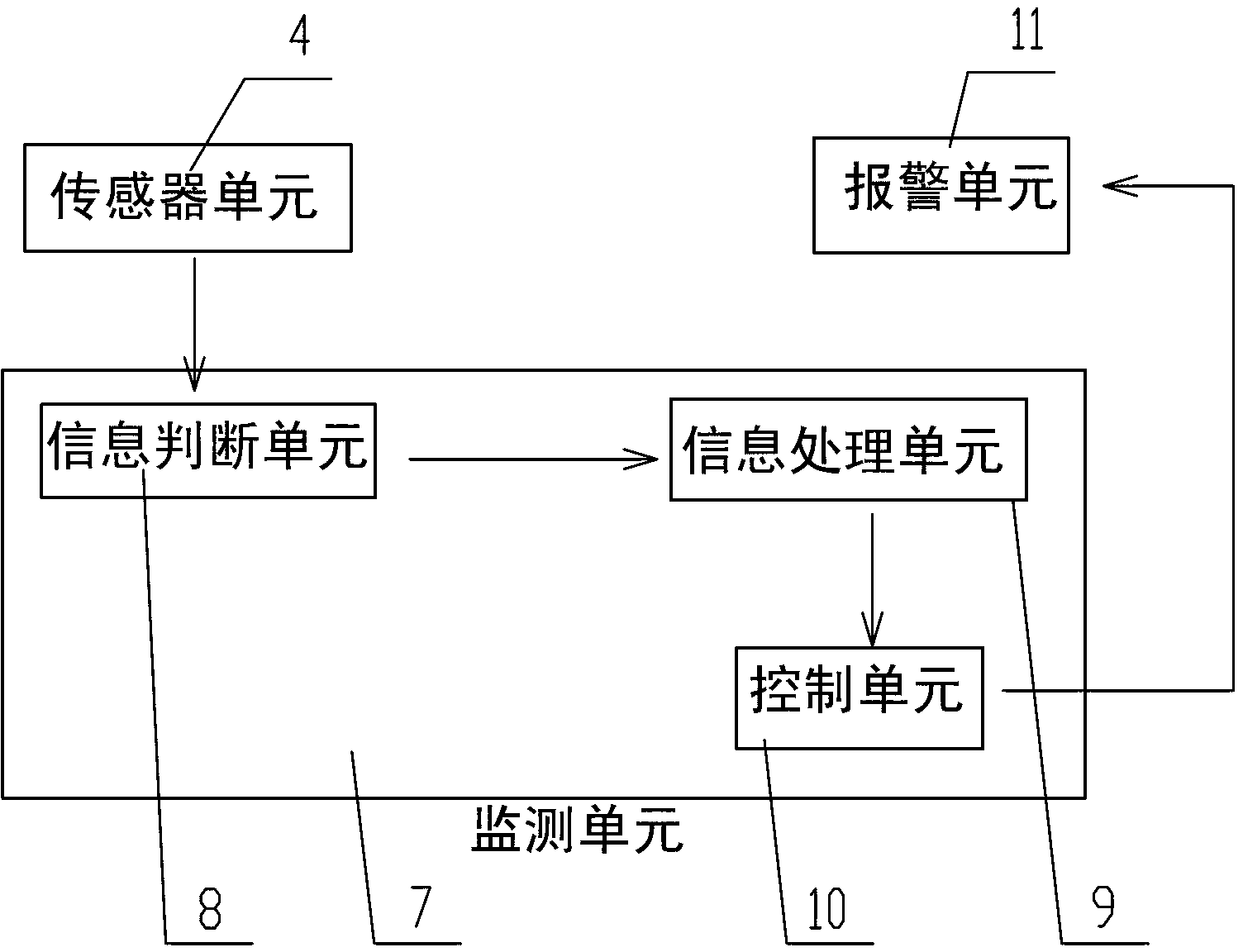

[0012] Refer to the attached figure 1 And attached figure 2 The winch lifting system with overweight warning function of the present invention will be described in detail below.

[0013] The winch lifting system with overweight early warning function of the present invention has a structure comprising a hoist bucket 6, a steel wire rope 3, a reel 2 and a reducer 1, the upper part of the hoist bucket 6 is provided with a redirection pulley 5, and the steel wire rope 3 Bypassing the reversing pulley 5, one end is connected to the reel 2, the reel 2 is connected to the reducer 1 through a shaft key, and the other end of the wire rope 3 bypassing the reversing pulley 5 is connected to the overweight early warning system, The overweight early warning system includes a sensor unit 4, a detection unit 7 and an alarm unit 11, the sensor unit 4 is arranged on the wire rope 3, the sensor unit 4 is connected to the detection unit 7, and the detection unit 7 is connected to the detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com