Method for preparing anhydrous neodymium chloride under open system

A technology of neodymium trichloride hexahydrate and neodymium chloride, which is applied in chemical instruments and methods, inorganic chemistry, rare earth metal compounds, etc., and can solve problems such as vacuum environment preparation process and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

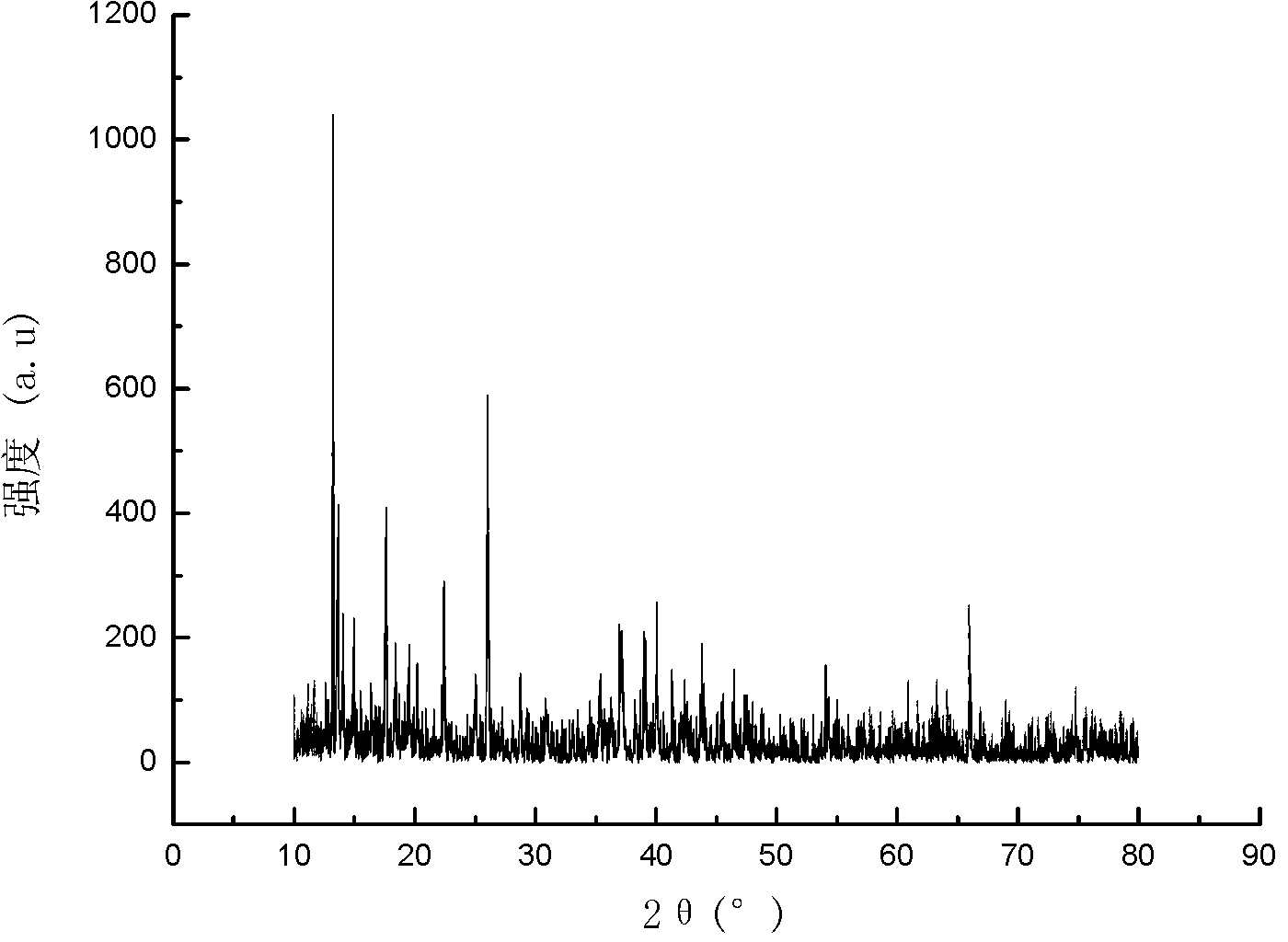

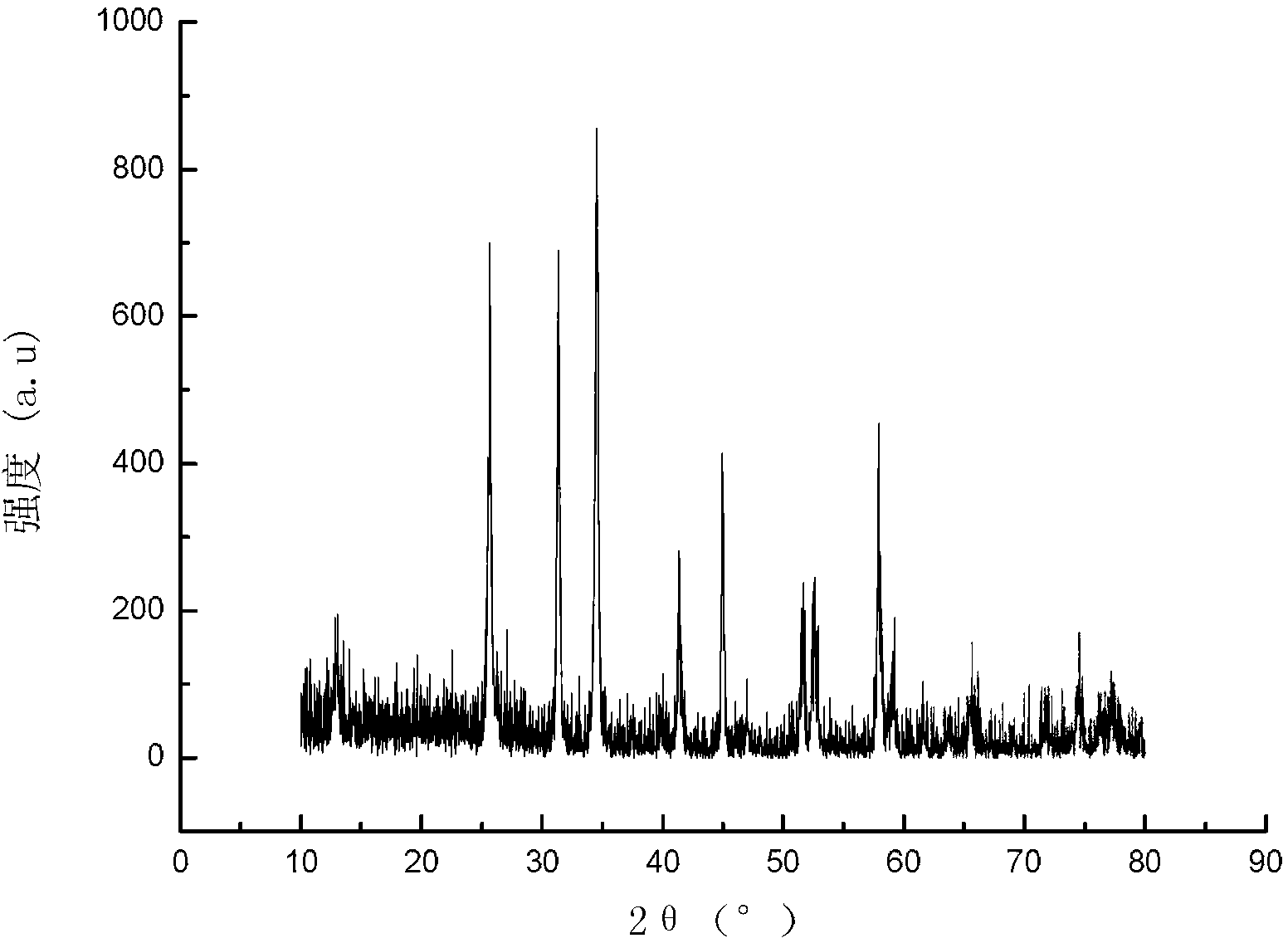

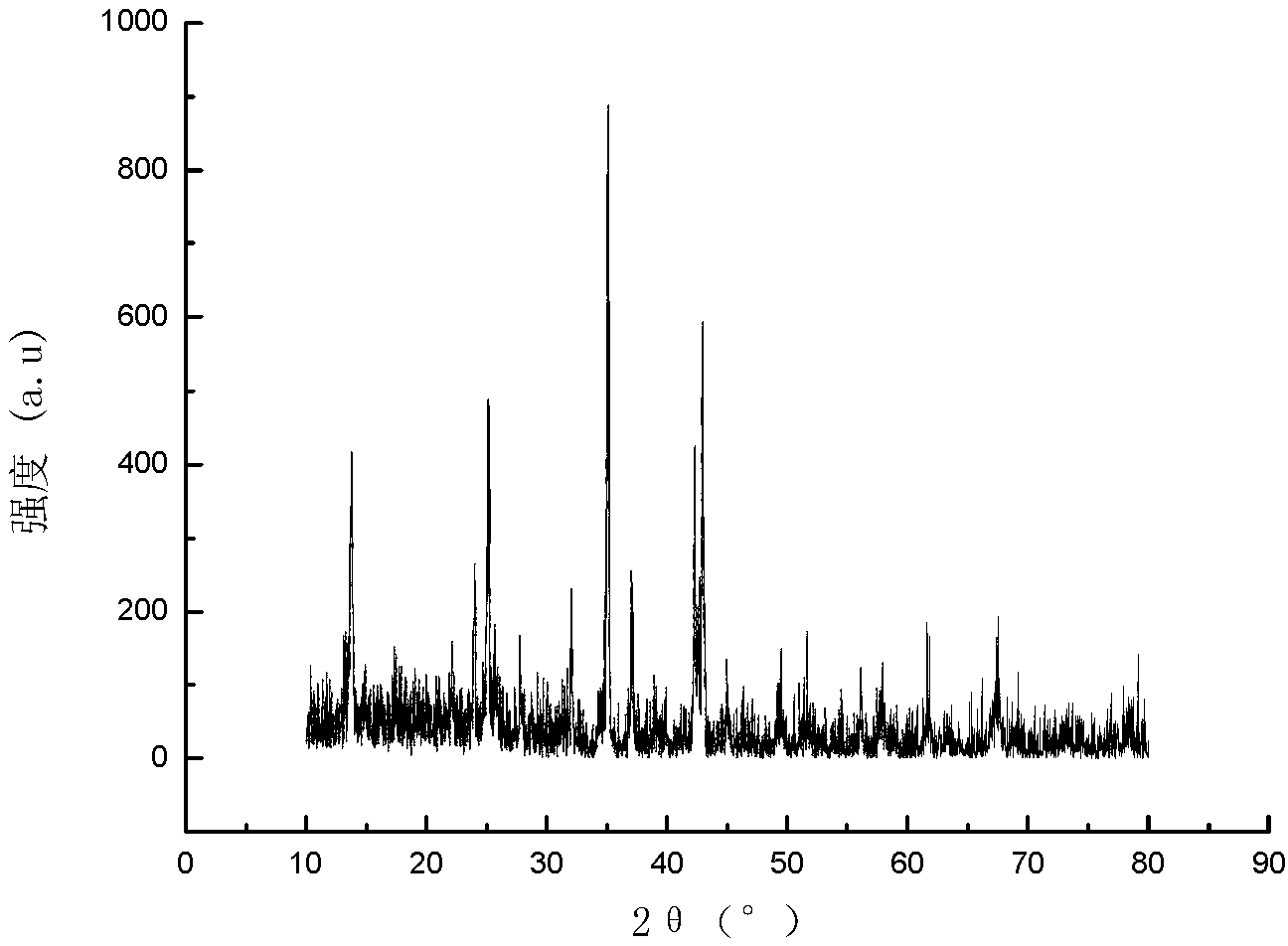

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: a kind of method for preparing anhydrous neodymium chloride under the open system of this embodiment, is to carry out through the following steps:

[0018] 1. Preparation of neodymium trichloride hexahydrate from neodymium oxide: a. Take neodymium oxide and place it in a 50°C oven for 50-70 minutes to obtain pretreated neodymium oxide; b. Add distilled water to the pretreated neodymium oxide, mix uniform; then under the condition of a constant temperature water bath at 70°C, add hydrochloric acid with a mass percentage of 36.6%, stir for 1-2 hours, then filter and keep the filtrate; c, under the condition of a water bath at 75°C, heat the filtrate for 5-8 hours , then washed with acetone, then filtered, then dried and ground to obtain neodymium trichloride hexahydrate; wherein the mass volume ratio of pretreated neodymium oxide to distilled water is 1g:5-10mL, and the pretreated neodymium oxide and distilled water The mass percentage composition...

specific Embodiment approach 2

[0026] Embodiment 2: This embodiment differs from Embodiment 1 in that in step 1, neodymium oxide is placed in an oven at 50° C. for 60 minutes. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the mass volume ratio of pretreated neodymium oxide to distilled water in step 1 is 1g: 8mL. Other steps and parameters are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com